Method for recycling cyanide through high-pressure circulating countercurrent washing of cyanidation tailings

A high-pressure circulation, countercurrent washing technology, applied in metal cyanide, chemical instruments and methods, simple alkali metal cyanide, etc., can solve the problems of unstable treatment effect, easy generation of sulfur dioxide, affecting process indicators, etc., to achieve environmental and economical Significant social benefits, good washing effect and safe process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

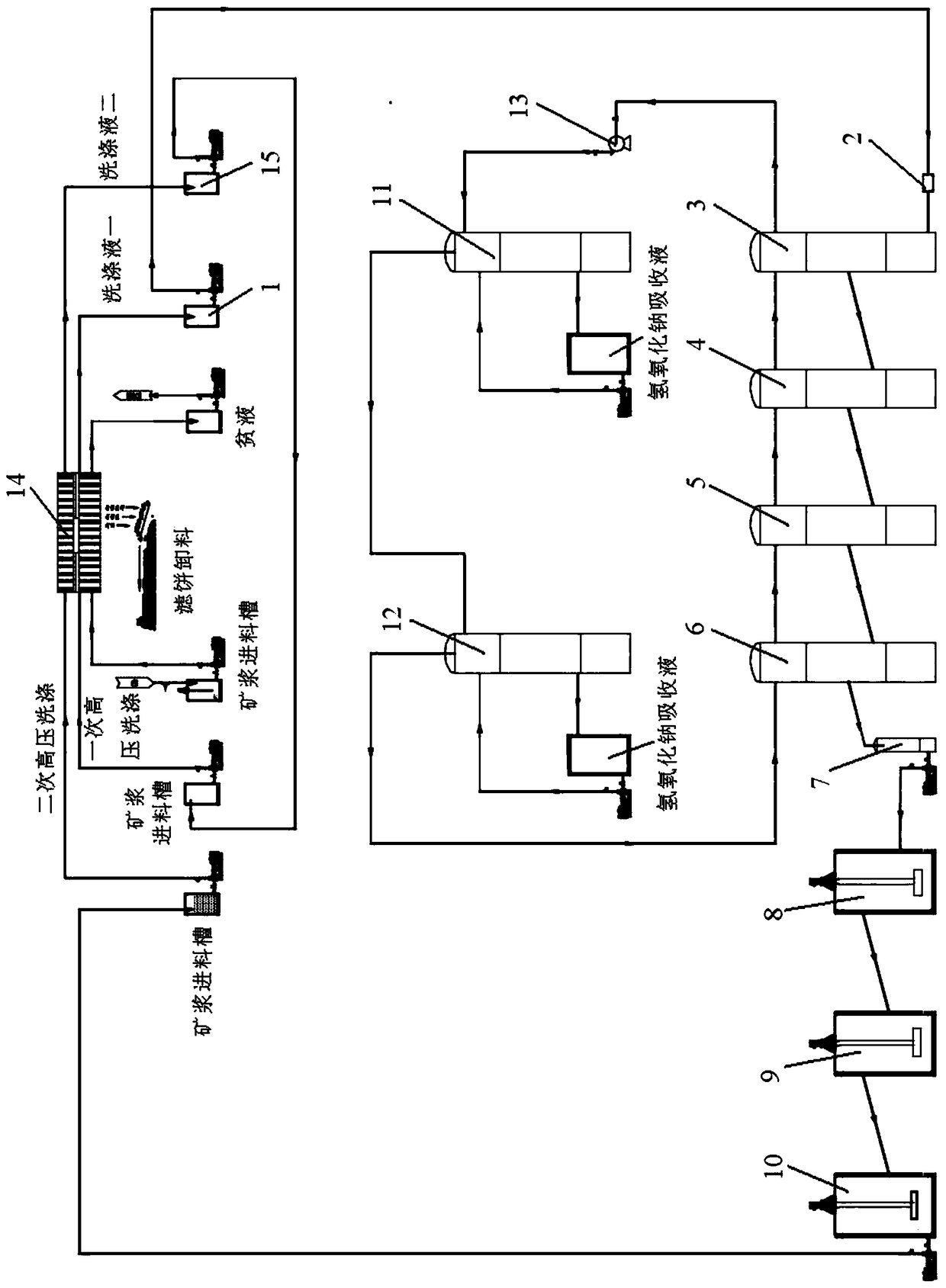

[0029] Include the following steps:

[0030] (1) Pass the high-concentration cyanide-containing ore slurry into the compacted filter press 14 for pressure filtration to form a filter cake;

[0031] (2) Maintain the compacted state of the filter press, carry out "one-time high-pressure washing" with clear water, and the washing liquid evenly passes through the filter cake to produce washing liquid one;

[0032] (3) Maintain the compacted state of the filter press, carry out "secondary high-pressure washing" with clear water, and the washing liquid evenly passes through the filter cake to produce washing liquid two;

[0033] (4) The washing liquid one directly enters the buffer tank one 1, pumps into the heater 2, and flows into the reactor one 3, reactor two 4, reactor three 5, reactor four 6, buffer tank two 7, and pumps into the middle And tank one 8, self-flow enters neutralization tank two 9, and then enters buffer tank three 10;

[0034] (5) Add an appropriate amount of ...

Embodiment 2

[0051] Include the following steps:

[0052] (1) Pass the high-concentration cyanide-containing ore slurry into the compacted filter press 14 for pressure filtration to form a filter cake;

[0053] (2) Maintain the compacted state of the filter press, carry out "one-time high-pressure washing" with clear water, and the washing liquid evenly passes through the filter cake to produce washing liquid one;

[0054] (3) Maintain the compacted state of the filter press, carry out "secondary high-pressure washing" with clear water, and the washing liquid evenly passes through the filter cake to produce washing liquid two;

[0055](4) The washing liquid one directly enters the buffer tank one 1, pumps into the heater 2, and flows into the reactor one 3, reactor two 4, reactor three 5, reactor four 6, buffer tank two 7, and pumps into the middle And tank one 8, self-flow enters neutralization tank two 9, and then enters buffer tank three 10;

[0056] (5) Add an appropriate amount of c...

Embodiment 3

[0073] Include the following steps:

[0074] (1) Pass the high-concentration cyanide-containing ore slurry into the compacted filter press 14 for pressure filtration to form a filter cake;

[0075] (2) Maintain the compacted state of the filter press, carry out "one-time high-pressure washing" with clear water, and the washing liquid evenly passes through the filter cake to produce washing liquid one;

[0076] (3) Maintain the compacted state of the filter press, carry out "secondary high-pressure washing" with clear water, and the washing liquid evenly passes through the filter cake to produce washing liquid two;

[0077] (4) The washing liquid one directly enters the buffer tank one 1, pumps into the heater 2, and flows into the reactor one 3, reactor two 4, reactor three 5, reactor four 6, buffer tank two 7, and pumps into the middle And tank one 8, self-flow enters neutralization tank two 9, and then enters buffer tank three 10;

[0078] (5) Add an appropriate amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com