Energy-saving type mud-head-free automatic green brick cutting device

An energy-saving and billet-cutting technology, which is applied in the direction of ceramic molding machines and manufacturing tools, can solve the problems of unfavorable energy saving, time-consuming, and rising production costs, and achieve the effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

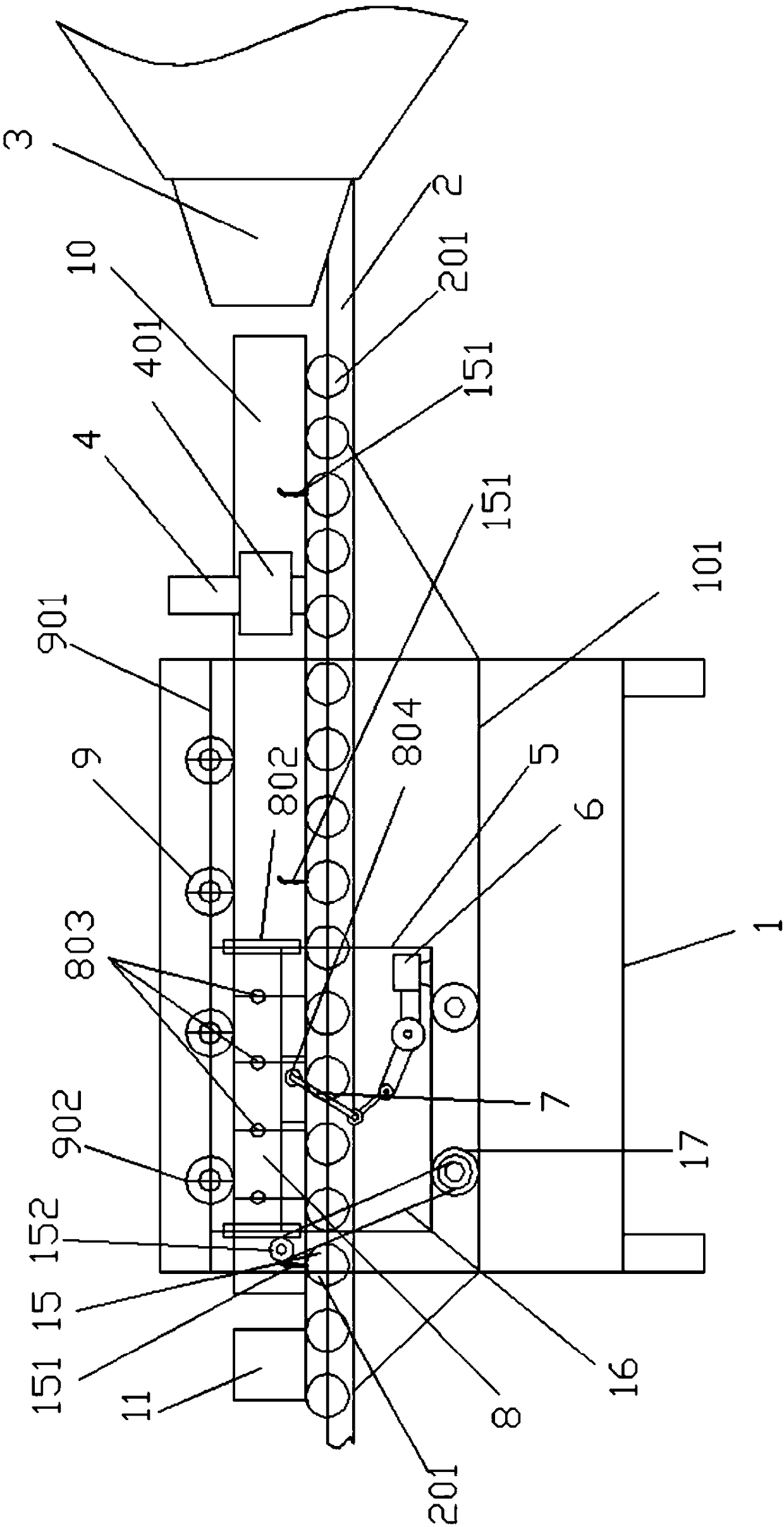

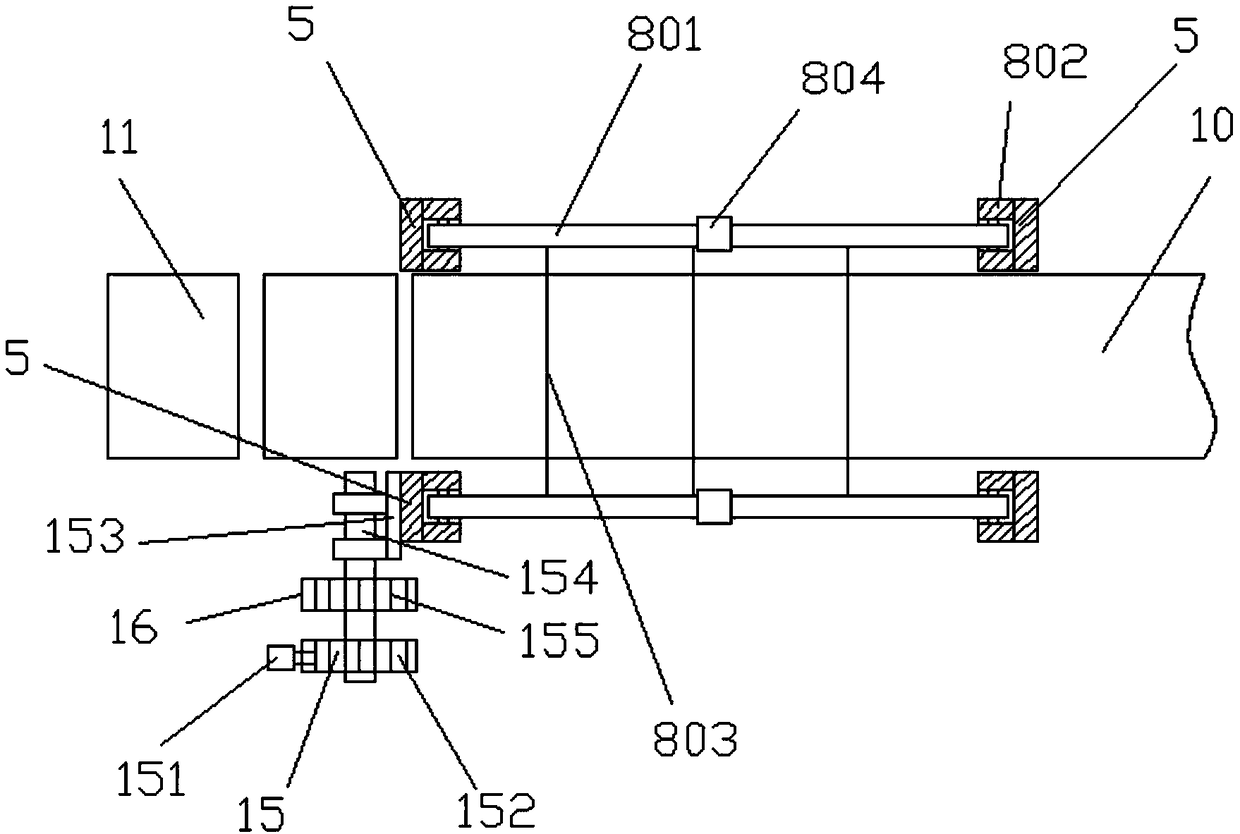

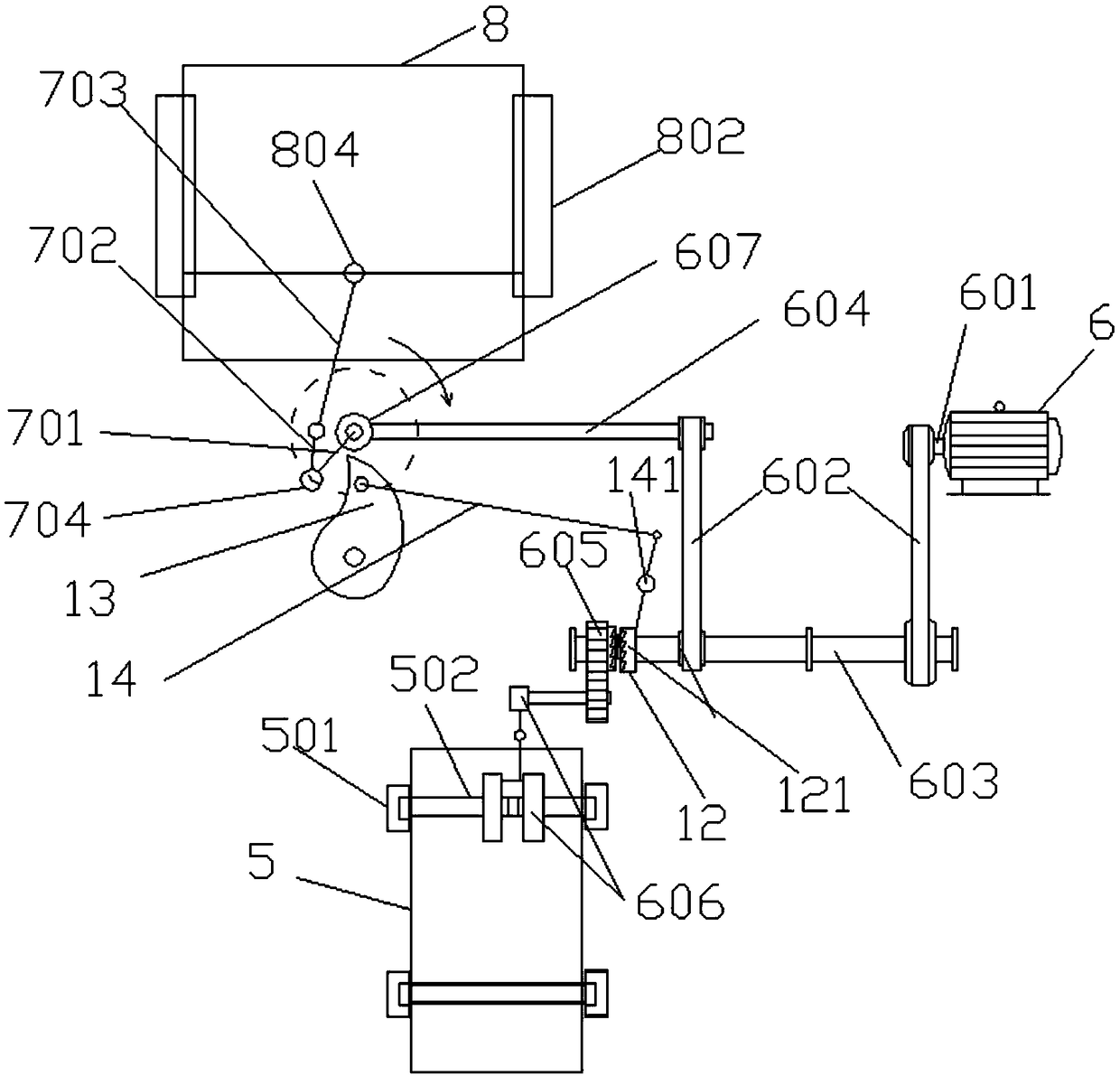

[0032] Attached below Figure 1-9 as well as Figure 10-Figure 11 Specific examples of the present invention are described.

[0033]The following examples facilitate a better understanding of the present invention, but do not limit the present invention. The following embodiments are only some of the embodiments of the present invention, but not all of them. The components used in the following examples are commercially available unless otherwise specified. The implementation of the control circuit in the following embodiments is a conventional control method unless otherwise specified.

[0034] In the present invention, unless otherwise clearly specified and limited, in the absence of a contrary description, the orientation words included in the terms such as "up, down, left, right, inside, outside, vertical, horizontal" are only It represents the orientation of the term in conventional use, or for the convenience of describing the present invention and simplification of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com