Fe2O3/SnO2 composite material and preparation method and application thereof and lithium-ion battery

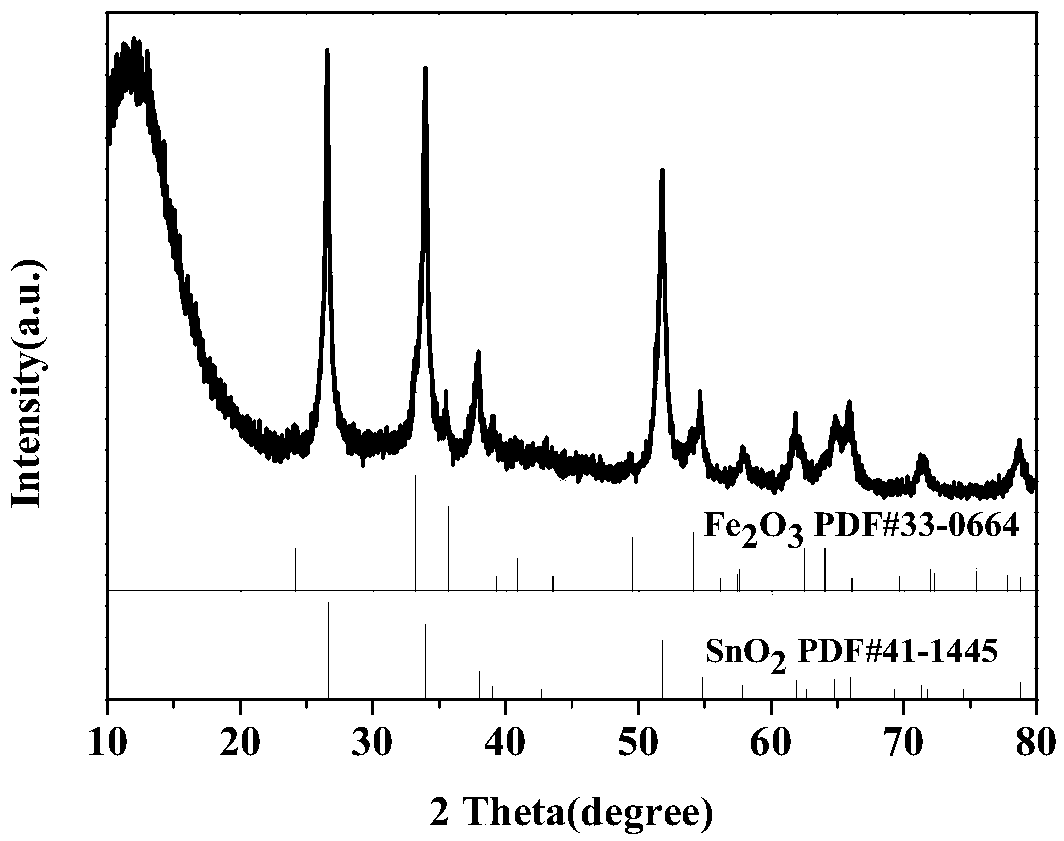

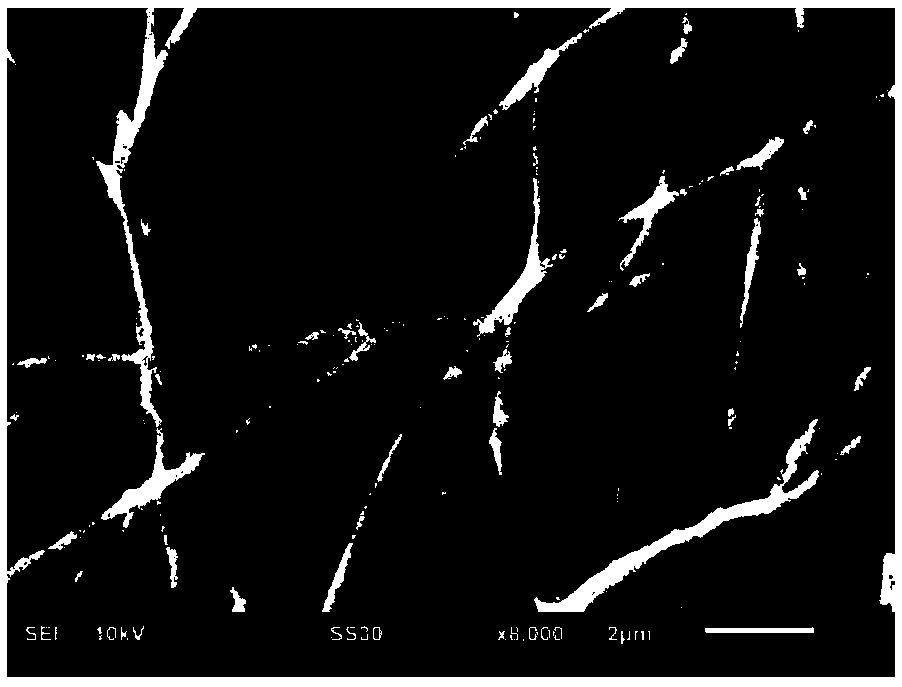

A lithium-ion battery and composite material technology, which is applied in the preparation of lithium-ion battery electrode materials, its preparation, and Fe2O3/SnO2 composite materials, can solve the problem that the morphology of two-component oxides is difficult to control, and the microscopic morphology of alloy oxides is amorphous. , The purity of metal oxides is not high, etc., to achieve the effect of small grain size, good fibrous morphology, and large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] According to a second aspect of the present invention, there is provided a Fe 2 o 3 / SnO 2 The preparation method of composite material, comprises the following steps:

[0053] Add tin salt and iron salt to the electrospinning solution, mix them evenly, and then perform electrospinning to obtain the primary product. The primary product is dried and heat-treated in an air atmosphere to obtain Fe 2 o 3 / SnO 2 composite materials;

[0054] Preferably, the tin salt is one of stannous chloride, stannous oxalate, tin tetrachloride or stannous sulfate, preferably stannous chloride;

[0055] Preferably, the iron salt is one of ferric acetylacetonate, ferric chloride, ferrous oxalate or ferrous sulfate, preferably ferric acetylacetonate;

[0056] Preferably, the electrospinning solution includes a polymer and a solvent;

[0057] Preferably, the polymer is one of polyacrylonitrile, polystyrene, polyvinyl alcohol or polyvinylpyrrolidone, preferably polyacrylonitrile;

[00...

Embodiment 1

[0108] a kind of Fe 2 o 3 / SnO 2 The preparation method of composite material, comprises the following steps:

[0109] (1) 1.80 parts by weight of polyacrylonitrile and 12.00 parts by weight of N,N-dimethylformamide are mixed uniformly to form a mixed solution;

[0110] (2) Add 0.70 parts by weight of stannous chloride and 0.44 parts by weight of iron acetylacetonate into the mixed solution, and mix at 45°C for 11 hours;

[0111](3) The mixed solution obtained in step (2) is subjected to electrospinning to obtain the primary product. The process parameters of the electrospinning include: the inner diameter of the syringe needle is 0.4mm, the voltage of the electrospinning is 15kV, and the scanning stroke is 35mm. The flow rate is 0.8mL / h, the distance between the collecting plate and the needle is 12cm, and the aluminum foil collects the spinning sample to obtain the primary product;

[0112] (4) drying the primary product, drying in a vacuum oven, the drying temperature i...

Embodiment 2

[0116] a kind of Fe 2 o 3 / SnO 2 The preparation method of composite material, comprises the following steps:

[0117] (1) 2.20 parts by weight of polyacrylonitrile and 13.00 parts by weight of N,N-dimethylformamide are mixed uniformly to form a mixed solution;

[0118] (2) Add 0.75 parts by weight of stannous chloride and 0.88 parts by weight of iron acetylacetonate into the mixed solution, and mix at 50° C. for 12 hours;

[0119] (3) The mixed solution obtained in step (2) is subjected to electrospinning to obtain the primary product. The process parameters of the electrospinning include: the inner diameter of the syringe needle is 0.6mm, the voltage of the electrospinning is 16kV, and the scanning stroke is 40mm. The flow rate is 1.0mL / h, the distance between the collecting plate and the needle is 15cm, and the spinning sample is collected to obtain the primary product;

[0120] (4) drying the initial product, drying in a vacuum oven, the drying temperature is 60°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com