A Method for Indirect Measurement of Fluid Temperature in Radiator Tube of Indirect Air Cooling System

A technology of radiator tube and measurement method, which is applied in the direction of temperature measurement of moving fluids, can solve problems such as uneconomical operation, energy consumption, complex radiator repair process, etc., to reduce the frequency of field measurements, efficient solutions and guidance, The effect of preventing and treating tube bundle frostbite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

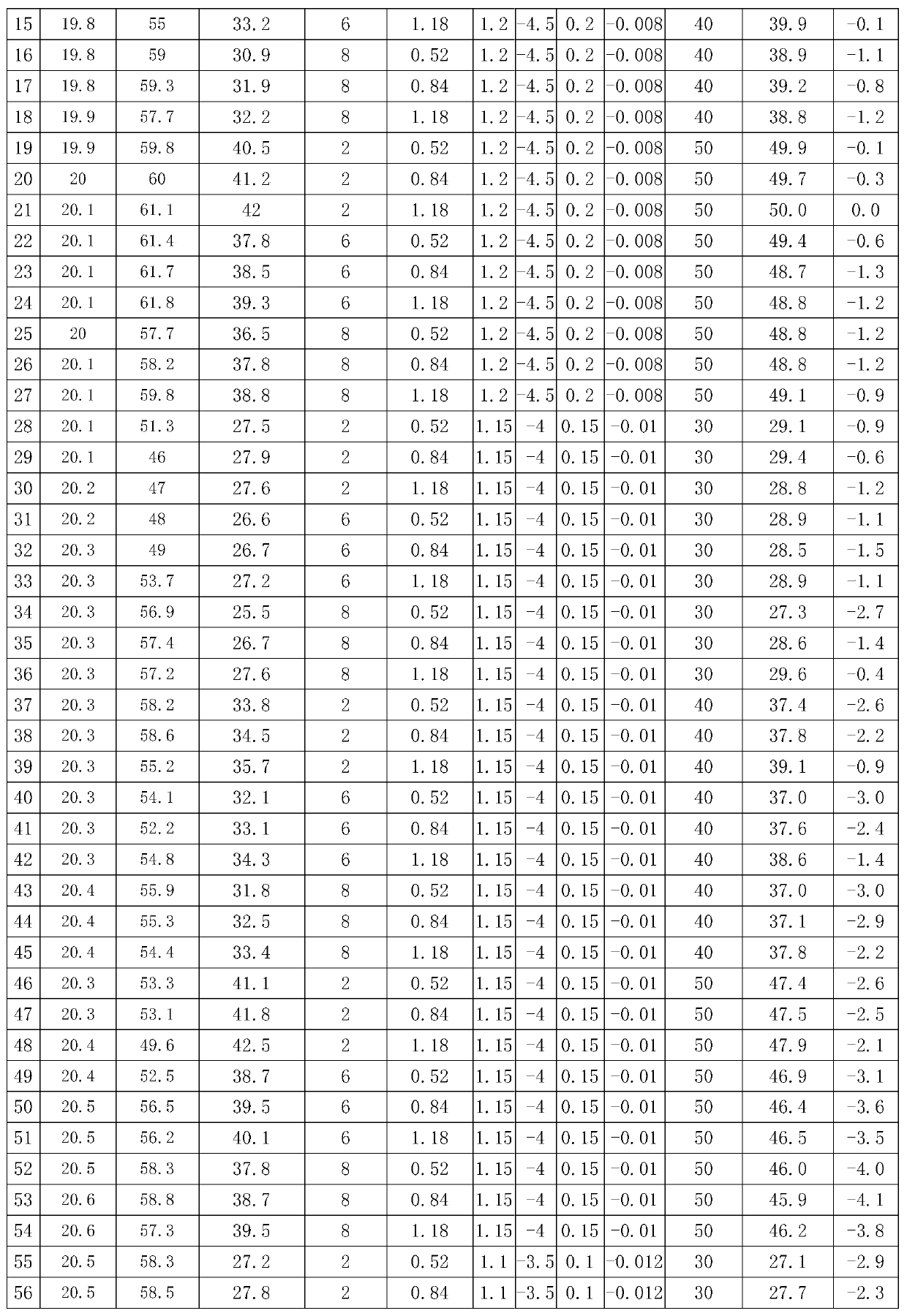

[0020] The present invention will be further described in detail in combination with experimental data and specific examples below.

[0021] This indirect measurement method is to build an experimental model of the indirect air condenser that can simulate various working conditions, and integrate the radiator with the indirect air condenser The temperature parameter associated with the temperature of the fluid in the pipe is an indirect measurement method obtained by integrating the experimental data of the associated temperature parameter, comprising the following steps:

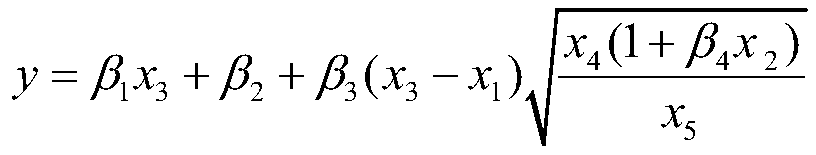

[0022] a. Obtain the associated temperature parameters, the associated temperature parameters include the ambient temperature x of the indirect air condenser 1 , the ambient relative humidity of the indirect air condenser x 2 , indirect air condenser radiator tube wall temperature x 3 , Ambient wind speed of indirect air condenser x 4 and the velocity of water flow in the radiator tube of the indirect a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com