A kind of nano-bismuth vanadate-zinc electroplating layer and its preparation method and application

A bismuth vanadate and zinc electroplating technology, which is applied in coatings, electrolytic components, electrolytic processes, etc., can solve the problems of poor mechanical properties, inability to apply to real sea application environments, and inability to apply nano-photocatalytic materials, etc., to achieve a good barrier effect , strong substrate bonding method, corrosion resistance and photocatalytic antibacterial performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

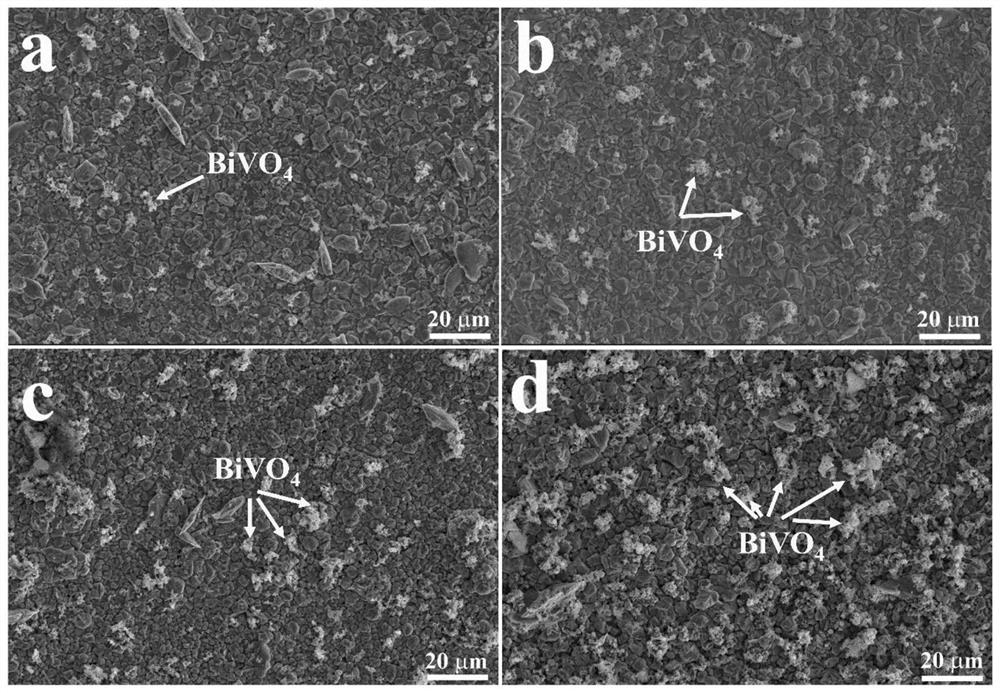

[0035] Preparation of nano-bismuth vanadate-zinc composite electroplating layer

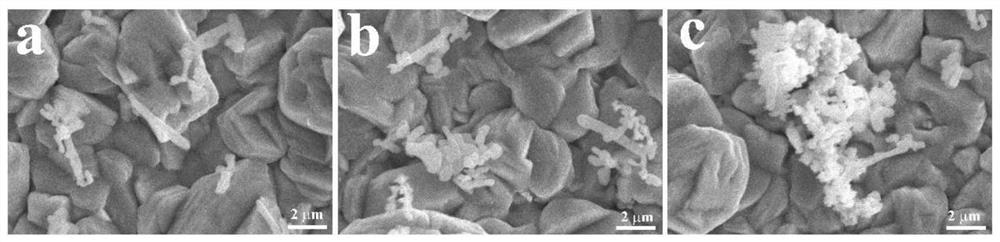

[0036] 1) Preparation of dendritic bismuth vanadate: Bi(NO 3 ) 3 ·5H 2 O nitric acid solution as A solution; in NH 4 VO 3Add polyvinylpyrrolidone (PVP) to the NaOH solution to obtain solution B; then add solution B dropwise to solution A under magnetic stirring, and adjust the pH of the suspension to 7, and continue to stir for 60 minutes; transfer the suspension to In a high-pressure reactor, heat treatment at 160°C for 24 hours; after the reaction, the product was filtered to obtain dendritic nano-BiVO 4 [2] .

[0037] Among them, A solution is Bi(NO 3 ) 3 ·5H 2 Nitric acid solution of O, where Bi(NO 3 ) 3 ·5H 2 O and HNO 3 The ratio of the amount of substances is 1:10; B solution is NH 4 VO 3 NaOH solution, where NaOH and NH 4 VO 3 The ratio of the amount of substances is 1:10, then in 100mLNH 4 VO 3 Add 0.5 g of PVP to the NaOH solution.

Embodiment 2

[0050] Comparison of current efficiency between nano-bismuth vanadate-zinc electroplating layer and pure zinc electroplating layer:

[0051] The nanometer bismuth vanadate-zinc electroplating layer is prepared for the above-mentioned embodiment 1;

[0052] The pure zinc electroplating layer is: prepared in SBlank under the same electrodeposition conditions as the nano-bismuth vanadate-zinc electroplating layer;

[0053] Then to pure zinc electroplating layer and nanometer bismuth vanadate-zinc electroplating layer, weigh coating quality before and after deposition, calculate the cathodic current efficiency in the deposition process according to formula (1) (referring to Figure 4 ).

[0054]

[0055] Among them, η c is the cathode current efficiency; m 1 is the mass of the sample before deposition, g; m 2 is the mass of the sample after deposition, g; e is the charge carried by electrons, C; j is the current density, mA cm -2 ; S is the deposition reaction area exposed...

Embodiment 3

[0058] Antibacterial performance of nano-bismuth vanadate-zinc electroplating coating

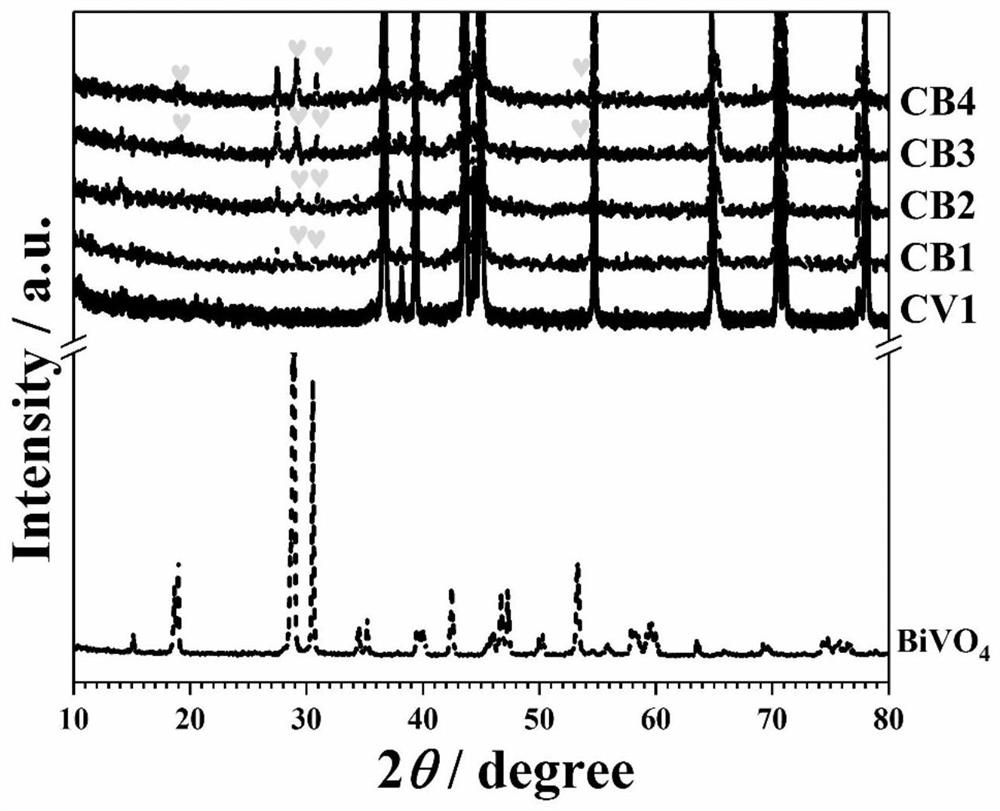

[0059] Prepare pure zinc electroplating layer (CB1, CB2, CB3, CB4) and nanometer bismuth vanadate-zinc electroplating layer (CV1, CV2, CV3, CV4) according to step in embodiment 1, soak in 10 7 cfu / mL Escherichia coli (E.coli) phosphate-buffered saline (PBS) bacteria solution, soaked in the dark state and 4000mW visible light conditions for 2h respectively. After taking out, utilize the K2081 type dyeing agent of APE Company to carry out fluorescence microscope observation after the bacteria staining on the coating surface ( Figure 5 ), and calculate the attachment rate ( Figure 6 ).

[0060] Taking the pure zinc electroplating layer CB2 and the nano-bismuth vanadate-zinc electroplating layer CB2 prepared under the condition of 15W ultrasonic as an example, the fluorescence micrographs are as follows: Figure 5 shown. The stained bacterial cells can fluoresce and appear as bright spots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com