Novel interior decorating material for automobile and modification method thereof

An automotive interior and modification technology, applied in chemical instruments and methods, vehicle parts, other household appliances, etc., can solve the problems of increased surface tension, limited effect, and few polar groups of skeleton materials, so as to improve the surface Tension, improved impact resistance, easy-to-react effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

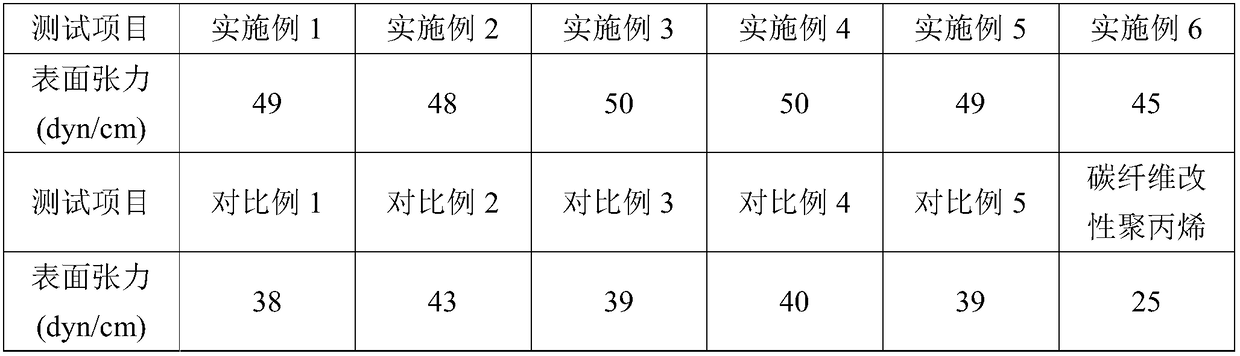

Examples

Embodiment 1

[0053] A new type of automotive interior material, including sequentially laminated skin layer, foam layer, TPU hot melt adhesive layer and skeleton material;

[0054] Among them, the skin layer is made of polyolefin, the foam layer is TPU microporous foam layer, and the skeleton material is carbon fiber modified polypropylene.

[0055] A method for modifying the above-mentioned novel automotive interior material, comprising the steps of:

[0056] (1) Pretreatment: select carbon fiber modified polypropylene skeleton material, polish its surface with SiC sandpaper, and then clean it with absolute ethanol;

[0057] (2) Disperse the modifier in water to form an emulsion, and then coat it on the surface of the pretreated skeleton material, dry and solidify at 50°C to form a modified coating with a thickness of 10 μm;

[0058] Wherein, modifier is by the polypropylene of 40wt% 4-methyl-5-vinyl thiazole ethylene disulfonate, 40wt% hydroxyethyl acrylate and 20wt% maleic anhydride gr...

Embodiment 2

[0064] A new type of automotive interior material, including sequentially laminated skin layer, foam layer, TPU hot melt adhesive layer and skeleton material;

[0065] Among them, the skin layer is made of polyolefin, the foam layer is EVA microporous foam layer, and the skeleton material is carbon fiber modified polypropylene.

[0066] A method for modifying the above-mentioned novel automotive interior material, comprising the steps of:

[0067] (1) Pretreatment: select carbon fiber modified polypropylene skeleton material, polish its surface with SiC sandpaper, and then clean it with absolute ethanol;

[0068] (2) Disperse the modifier in water to form an emulsion, and then coat it on the surface of the pretreated framework material, dry and solidify at 70°C to form a modified coating with a thickness of 20 μm;

[0069] Wherein, modifier is made up of 60wt% sodium allyl sulfonate, 30wt% hydroxypropyl methacrylate and 10wt% maleic anhydride grafted polypropylene (grafting r...

Embodiment 3

[0075] A new type of automotive interior material, including sequentially laminated skin layer, foam layer, TPU hot melt adhesive layer and skeleton material;

[0076] Among them, the skin layer is made of polyurethane, the foam layer is PU microporous foam layer, and the skeleton material is carbon fiber modified polypropylene.

[0077] A method for modifying the above-mentioned novel automotive interior material, comprising the steps of:

[0078] (1) Pretreatment: select carbon fiber modified polypropylene skeleton material, polish its surface with SiC sandpaper, and then clean it with absolute ethanol;

[0079] (2) Disperse the modifier in water to form an emulsion, and then coat it on the surface of the pretreated framework material, dry and solidify at 55°C to form a modified coating with a thickness of 15 μm;

[0080] Wherein, modifying agent is by the polypropylene of 50wt% 1-allyl-3-methylimidazole p-toluenesulfonate, 20wt% hydroxybutyl acrylate and 30wt% maleic anhyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com