Treatment method for strengthening mechanical properties of palm rattan weaving

A treatment method, rattan technology, applied in the field of arts and crafts, can solve the problems of poor weather resistance, waste of resources, and decline in mechanical properties, and achieve the effects of short production cycle, low cost, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

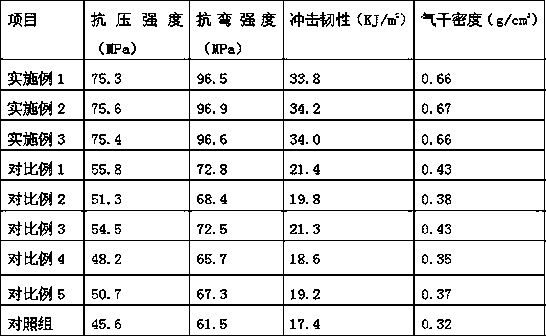

Examples

Embodiment 1

[0017] A processing method for enhancing the mechanical properties of palm rattan weaving, comprising the following steps:

[0018] (1) Mechanically peel the harvested palm rattan and dry it in the sun for 2 days, stir and bleach with bleach to remove the residual cortex on the surface, the stirring speed is 200 rpm, the bleaching temperature is 60°C, and the bleaching time is 20 minutes, and then placed in Heat treatment under steam, the steam pressure is 0.25MPa, the steam temperature is 100°C, and the treatment time is 1.5 hours;

[0019] (2) Rinse the heat-treated palm rattan with water for 2 times, then dry it, control the drying temperature at 60°C, dry it until the water content is between 10-12%, and then place it in a glue-containing agent for vacuum Dipping treatment, and then refrigerated at 0°C for 7 hours. After refrigerated, take out the rattan, scrub the surface and put it in an oven for drying. The oven is heated to 60°C and dried until the water content is bet...

Embodiment 2

[0026] A processing method for enhancing the mechanical properties of palm rattan weaving, comprising the following steps:

[0027] (1) Mechanically peel the harvested palm rattan and dry it in the sun for 2 days, stir and bleach with bleach to remove the residual cortex on the surface, the stirring speed is 220 rpm, the bleaching temperature is 65°C, and the bleaching time is 25 minutes, and then placed in Heat treatment under steam, the steam pressure is 0.28MPa, the steam temperature is 105°C, and the treatment time is 1.8 hours;

[0028] (2) Rinse the heat-treated palm rattan with water for 2 times, then dry it, control the drying temperature at 65°C, dry it until the water content is between 10-12%, and then place it in a glue-containing agent for vacuum Dipping treatment, and then refrigerated at 3°C for 8 hours. After refrigerated, take out the rattan, scrub the surface and put it in an oven for drying. The oven is heated to 65°C and dried until the water content is b...

Embodiment 3

[0035] A processing method for enhancing the mechanical properties of palm rattan weaving, comprising the following steps:

[0036] (1) Mechanically peel the harvested palm rattan and dry it in the sun for 3 days, stir and bleach with bleach to remove the residual cortex on the surface, the stirring speed is 240 rpm, the bleaching temperature is 70°C, and the bleaching time is 30 minutes, and then placed in Heat treatment under steam, the steam pressure is 0.30MPa, the steam temperature is 110°C, and the treatment time is 2.0 hours;

[0037](2) Rinse the heat-treated palm rattan with water for 3 times, then dry it at a controlled drying temperature of 70°C, dry it until the water content is between 10-12%, and then place it in a glue-containing agent for vacuum Dipping treatment, and then refrigerated at 5°C for 10 hours. After refrigerated, take out the rattan, scrub the surface and put it in an oven for drying. The oven is heated to 70°C and dried until the water content is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com