Submerged arc composite welding method of bridge steel thick plate with tensile strength greater than or equal to 810MPa

A tensile strength, composite welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of no preheating, etc., and achieve the effects of excellent crack resistance, excellent fracture toughness, and excellent low-temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The base material test plate size is 600mm×400mm×50mm for equal thickness welding;

[0033] A method for submerged arc composite welding of bridge steel thick plates with tensile strength ≥ 810MPa, the steps of which are as follows:

[0034] 1) Mechanical properties of the base material: The mechanical properties are characterized by: yield strength R eL 694MPa, tensile strength R m 817MPa, elongation A17%, -40℃KV 2 The impact energy is 231J; the thickness is 50mm equal thickness bridge steel;

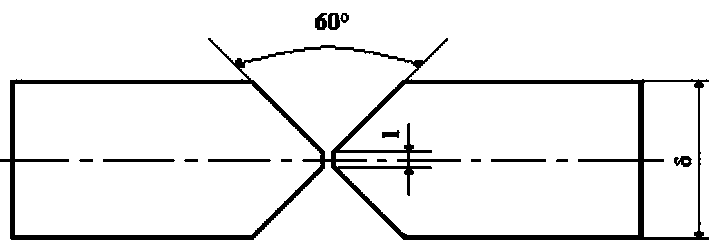

[0035] 2) The groove adopts double-sided V-shaped symmetrical groove, the groove angle is 60°, and the blunt edge is 1mm;

[0036] 3) Two matching welding wires: submerged arc welding wire adopts tensile strength of 888MPa, welding wire diameter Ф4.0mm; Mechanical properties of the deposited metal of the welding wire: tensile strength R m It is 888MPa, elongation A is 17%, reduction of area Z is 65%, -40℃KV 2 The impact energy is 118J;

[0037] The tensile strength of the...

Embodiment 2

[0043] The base material test plate size is 600mm×400mm×32mm for equal thickness welding;

[0044] A method for submerged arc composite welding of bridge steel thick plates with tensile strength ≥ 810MPa, the steps of which are as follows:

[0045] 1) Mechanical properties of the base material: The mechanical properties are characterized by: yield strength R eL 705MPa, tensile strength R m 874MPa, elongation A16%, -40℃KV 2 The impact energy is 210J; the thickness is 32mm equal thickness bridge steel;

[0046] 2) The groove adopts double-sided V-shaped symmetrical groove, the groove angle is 60°, and the blunt edge is 1mm;

[0047] 3) Two matching welding wires: submerged arc welding wire adopts tensile strength of 888MPa, welding wire diameter Ф4.0mm; Mechanical properties of the deposited metal of the welding wire: tensile strength R m It is 888MPa, elongation A is 17%, reduction of area Z is 65%, -40℃KV 2 The impact energy is 118J;

[0048] The tensile strength of the...

Embodiment 3

[0054] The base material test plate size is 600mm×400mm×50mm for equal thickness welding;

[0055] A method for submerged arc composite welding of bridge steel thick plates with tensile strength ≥ 810MPa, the steps of which are as follows:

[0056] 1) Mechanical properties of the base material: The mechanical properties are characterized by: yield strength R eL 694MPa, tensile strength R m 817MPa, elongation A17%, -40℃KV 2 The impact energy is 231J; the thickness is 50mm equal thickness bridge steel;

[0057] 2) The groove adopts double-sided V-shaped symmetrical groove, the groove angle is 60°, and the blunt edge is 1mm;

[0058] 3) Two matching welding wires: submerged arc welding wire adopts tensile strength of 888MPa, welding wire diameter Ф4.0mm; Mechanical properties of the deposited metal of the welding wire: tensile strength R m It is 888MPa, elongation A is 17%, reduction of area Z is 65%, -40℃KV 2 The impact energy is 118J;

[0059] The tensile strength of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com