A Submerged Arc Composite Welding Method for Bridge Steel Thick Plates with Tensile Strength≥810mpa

A tensile strength, composite welding technology, used in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem of non-preheating, and achieve the effects of excellent crack resistance, excellent fracture toughness, and easy welding process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The base material test plate size is 600mm×400mm×50mm for equal thickness welding;

[0033] A method for submerged arc composite welding of bridge steel thick plates with tensile strength ≥ 810MPa, the steps of which are as follows:

[0034] 1) Mechanical properties of the base material: The mechanical properties are characterized by: yield strength R eL 694MPa, tensile strength R m 817MPa, elongation A17%, -40℃KV 2 The impact energy is 231J; the thickness is 50mm equal thickness bridge steel;

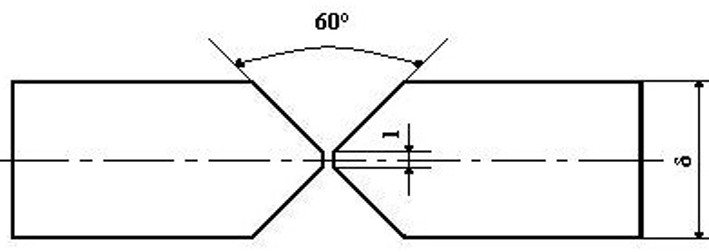

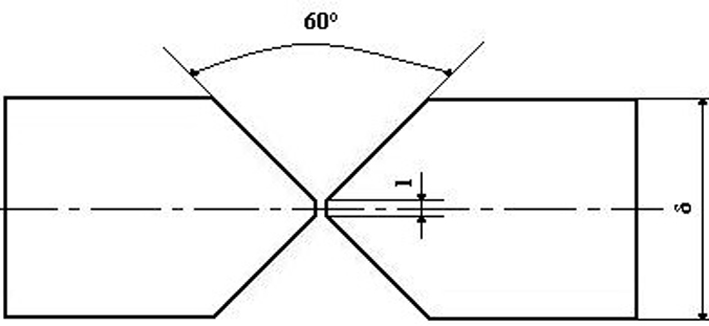

[0035] 2) The groove adopts double-sided V-shaped symmetrical groove, the groove angle is 60°, and the blunt edge is 1mm;

[0036] 3) Two matching welding wires: submerged arc welding wire adopts tensile strength of 888MPa, welding wire diameter Ф4.0mm; Mechanical properties of the deposited metal of the welding wire: tensile strength R m It is 888MPa, elongation A is 17%, reduction of area Z is 65%, -40℃KV 2 The impact energy is 118J;

[0037] The tensile strength of the...

Embodiment 2

[0043] The base material test plate size is 600mm×400mm×32mm for equal thickness welding;

[0044] A method for submerged arc composite welding of bridge steel thick plates with tensile strength ≥ 810MPa, the steps of which are as follows:

[0045] 1) Mechanical properties of the base material: The mechanical properties are characterized by: yield strength R eL 705MPa, tensile strength R m 874MPa, elongation A16%, -40℃KV 2 The impact energy is 210J; the thickness is 32mm equal thickness bridge steel;

[0046] 2) The groove adopts double-sided V-shaped symmetrical groove, the groove angle is 60°, and the blunt edge is 1mm;

[0047] 3) Two matching welding wires: submerged arc welding wire adopts tensile strength of 888MPa, welding wire diameter Ф4.0mm; Mechanical properties of the deposited metal of the welding wire: tensile strength R m It is 888MPa, elongation A is 17%, reduction of area Z is 65%, -40℃KV 2 The impact energy is 118J;

[0048] The tensile strength of the...

Embodiment 3

[0054] The base material test plate size is 600mm×400mm×50mm for equal thickness welding;

[0055] A method for submerged arc composite welding of bridge steel thick plates with tensile strength ≥ 810MPa, the steps of which are as follows:

[0056] 1) Mechanical properties of the base material: The mechanical properties are characterized by: yield strength R eL 694MPa, tensile strength R m 817MPa, elongation A17%, -40℃KV 2 The impact energy is 231J; the thickness is 50mm equal thickness bridge steel;

[0057] 2) The groove adopts double-sided V-shaped symmetrical groove, the groove angle is 60°, and the blunt edge is 1mm;

[0058] 3) Two matching welding wires: submerged arc welding wire adopts tensile strength of 888MPa, welding wire diameter Ф4.0mm; Mechanical properties of the deposited metal of the welding wire: tensile strength R m It is 888MPa, elongation A is 17%, reduction of area Z is 65%, -40℃KV 2 The impact energy is 118J;

[0059] The tensile strength of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com