A kind of high-strength and high-modulus dual-phase magnesium-lithium alloy and preparation method thereof

A technology of magnesium-lithium alloy and high modulus, which is applied in the field of magnesium alloy as a metal material, can solve problems such as low elongation, unreached strength, and unreached strength, so as to improve elastic modulus and strength, and achieve good solid solution strengthening Effect, the effect of improving the modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

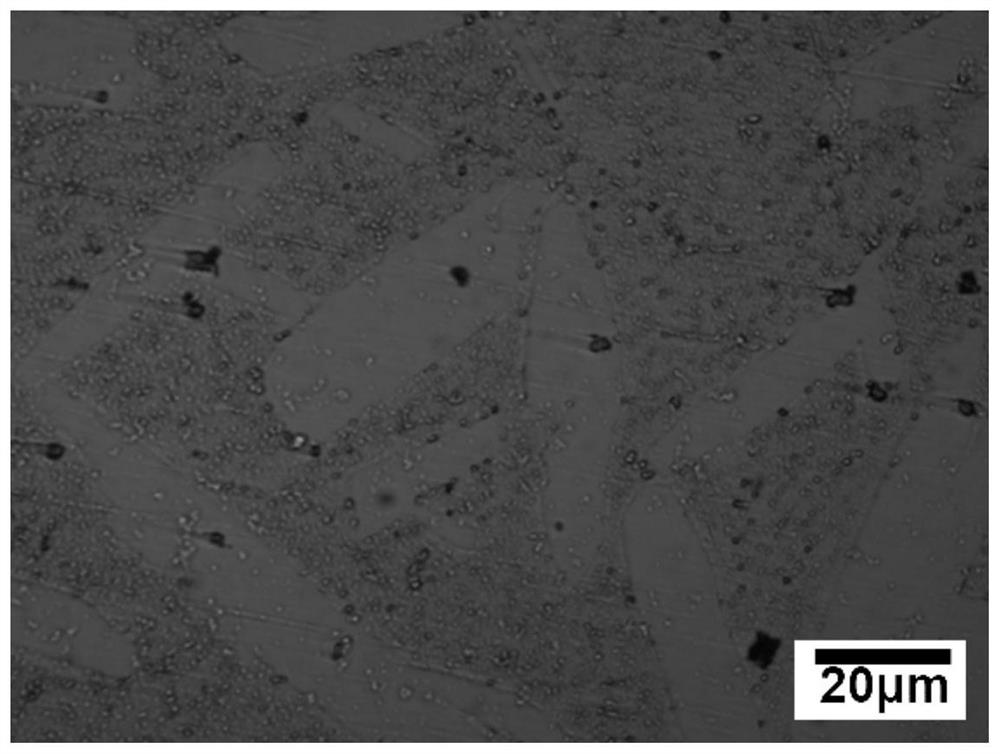

Image

Examples

Embodiment 1

[0065] The chemical composition of a high-strength and high-modulus dual-phase magnesium-lithium alloy is: Gd: 2.0wt.%, Al: 4.0wt.%, Y: 3.0wt.%, Li: 8.0wt.%, Zn: 3.0 wt.%, Mn: 1.0 wt.% The balance is Mg and inevitable impurities.

[0066] The preparation method of the high-strength and high-modulus dual-phase magnesium-lithium alloy comprises the following steps:

[0067] S1, raw material preparation stage

[0068] According to the mass percentage of raw material chemical components in the high-strength and high-modulus dual-phase magnesium-lithium alloy, the total weight is Mg-28wt.%Gd master alloy containing 2wt.%Gd, Mg-28wt.%Gd containing 3wt.%Y. %Y master alloy, Mg-28wt.%Mn master alloy with 1wt.%Mn, 4wt.% pure Al, 8wt.% pure Li, 3wt.% pure Zn, balance pure Mg; and surface oxides removed ;

[0069] S2, preheating raw material stage

[0070] Put the weighed raw materials and stainless steel crucible in step S1 into a heat treatment furnace and preheat at 200°C for 2 hou...

Embodiment 2

[0081] The chemical composition of a high-strength and high-modulus dual-phase magnesium-lithium alloy is as follows: Gd: 3.0wt.%, Al: 5.0wt.%, Y: 2.0wt.%, Li: 5.0wt.%, Zn: 4.0 wt.%, Mn: 3.0 wt.% The balance is Mg and inevitable impurities.

[0082] The preparation method of the high-strength and high-modulus dual-phase magnesium-lithium alloy comprises the following steps:

[0083] S1, raw material preparation stage

[0084] According to the mass percentage of raw material chemical components in the high-strength and high-modulus dual-phase magnesium-lithium alloy, the total mass is Mg-23wt.%Gd master alloy containing 3wt.%Gd, Mg-40wt.%Gd containing 2wt.%Y. %Y master alloy, Mg-20wt.%Mn master alloy with 3wt.%Mn, 5wt.%pure Al, 5wt.%pure Li, 4wt.%pure Zn, balance pure Mg; and surface oxides removed ;

[0085] S2, preheating raw material stage

[0086] Put the weighed raw materials and graphite crucible in step S1 into a heat treatment furnace and preheat at 220 ° C for 1.5 ...

Embodiment 3

[0097] The chemical composition of a high-strength and high-modulus dual-phase magnesium-lithium alloy is: Gd: 1.8wt.%, Al: 4.2wt.%, Y: 4.9wt.%, Li: 7.8wt.%, Zn: 1.8 wt.%, Mn: 3.1 wt.% The balance is Mg and inevitable impurities.

[0098] The preparation method of the high-strength and high-modulus dual-phase magnesium-lithium alloy comprises the following steps:

[0099] S1, raw material preparation stage

[0100] According to the mass percentage of raw material chemical components in the high-strength and high-modulus dual-phase magnesium-lithium alloy, the total weight is Mg-43wt.%Gd master alloy containing 2wt.%Gd, Mg-35wt.%Gd containing 5wt.%Y. %Y master alloy, Mg-25wt.%Mn master alloy with 3wt.%Mn, Mg-48wt.%Li master alloy with 8wt.%Li, 4wt.% pure Al, 2wt.% pure Zn, balance is pure Mg; and removes surface oxides;

[0101] S2, preheating raw material stage

[0102] Put the weighed raw materials and BN crucibles in step S1 into a heat treatment furnace and preheat at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com