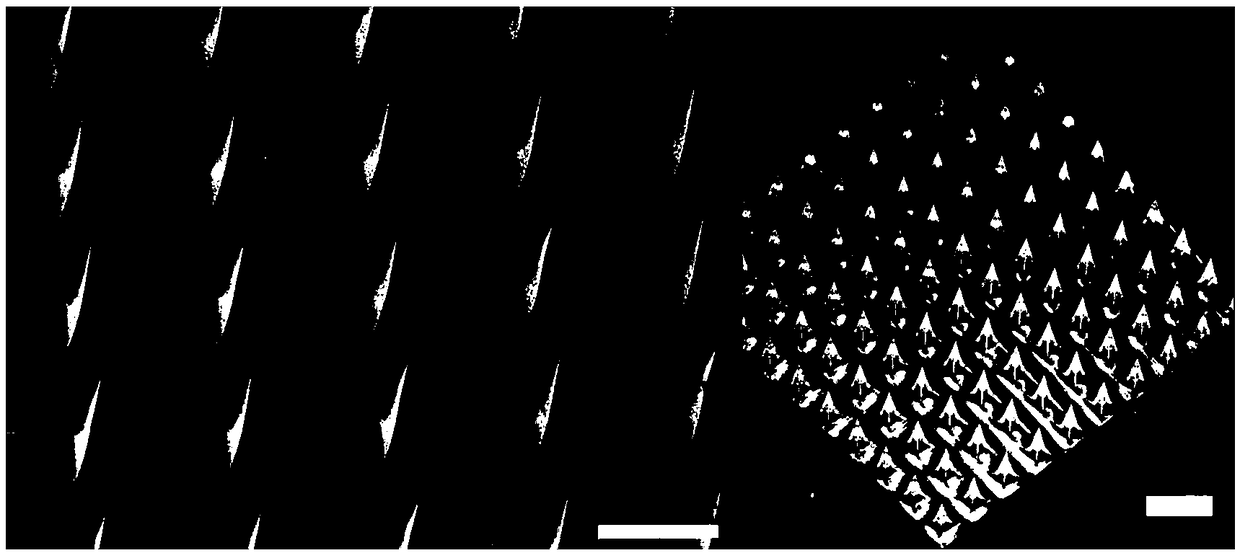

Self-adhesive microneedle patch capable of swelling rapidly and preparation method thereof

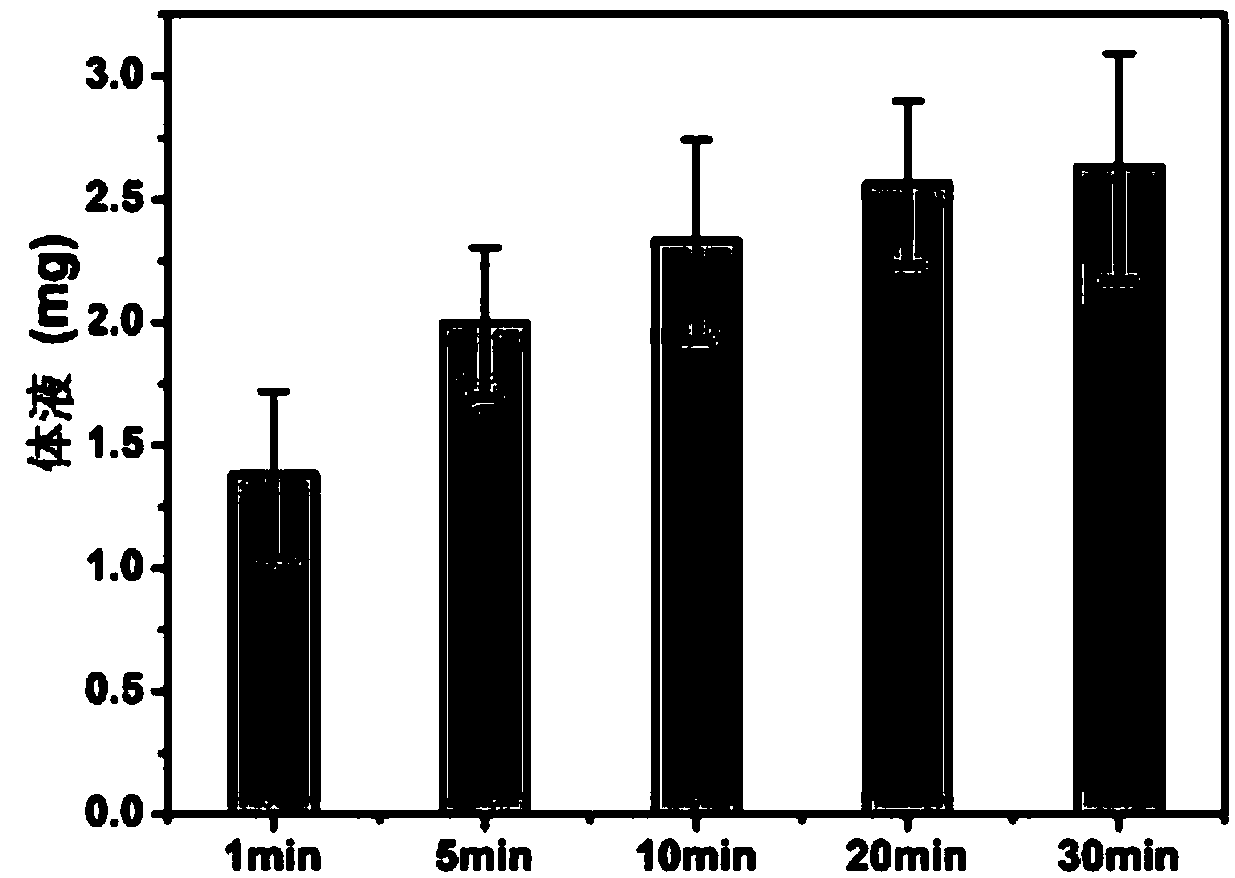

A microneedle patch and self-adhesive technology, applied in the direction of microneedles, needles, pharmaceutical formulations, etc., can solve problems such as allergic reactions, residues in the skin, and easy breakage, and achieve reduced time and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

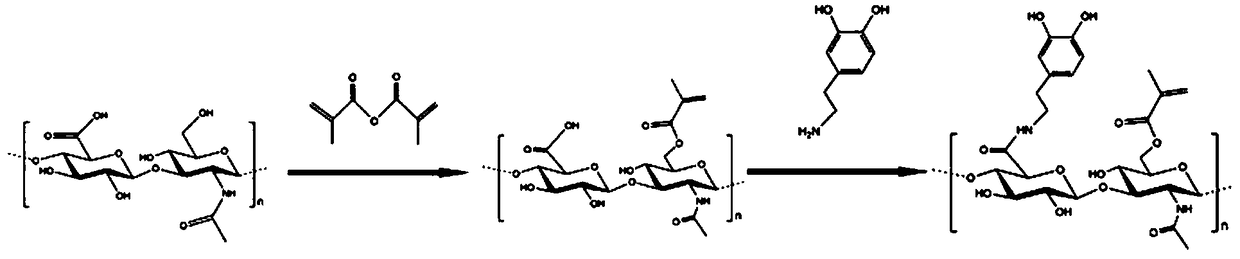

Method used

Image

Examples

Embodiment 1

[0026] (1) Dissolving hyaluronic acid in deionized water to form a hydrophilic polymer solution with a concentration of 20 mg / mL, and then adding methacrylic anhydride to the above solution for esterification to obtain mixture A; wherein the reaction conditions are: pH=8, the temperature is 4 degrees, the time is 24h; the stirring speed is 300rpm; the molar ratio of methacrylic anhydride to hyaluronic acid is 2:1;

[0027] (2) Extraction of the esterified hydrophilic polymer in the mixture A: first add ethanol to the mixture A for precipitation to obtain a precipitate, then use water to dissolve the precipitate, and then put it into a renewable fiber dialysis bag Carry out dialysis in deionized water for 5 days, and finally take out the regenerated fiber dialysis bag and freeze-dry to obtain the esterified hydrophilic polymer; wherein, the freeze-drying conditions are: temperature: -60 degrees, pressure: 1pa;

[0028](3) Dissolve the esterified hydrophilic polymer in deionized...

Embodiment 2

[0031] (1) Dissolving collagen in deionized water to form a hydrophilic polymer solution with a concentration of 50 mg / mL, then adding methacrylic anhydride to the above solution for esterification to obtain mixture A; wherein the reaction conditions are: pH= 9. The temperature is 10 degrees, the time is 36h; the stirring speed is 1000rpm; the molar ratio of methacrylic anhydride to collagen is 50:1;

[0032] (2) Extraction of the esterified hydrophilic polymer in the mixture A: first add ethanol to the mixture A for precipitation to obtain a precipitate, then use water to dissolve the precipitate, and then put it into a renewable fiber dialysis bag Carry out dialysis in deionized water for 3 days, and finally take out the regenerated fiber dialysis bag and freeze-dry to obtain the esterified hydrophilic polymer; wherein, the freeze-drying conditions are: temperature: -60 degrees, pressure: 10pa;

[0033] (3) Dissolve the esterified hydrophilic polymer in deionized water at a ...

Embodiment 3

[0036] (1) Dissolve alginic acid in deionized water to form a hydrophilic polymer solution with a concentration of 80 mg / mL, then add methacrylic anhydride to the above solution for esterification to obtain mixture A; wherein, the reaction conditions are: pH =8, the temperature is 10 degrees, the time is 30h; the stirring speed is 5000rpm; the molar ratio of methacrylic anhydride to alginic acid is 60:1;

[0037] (2) Extraction of the esterified hydrophilic polymer in the mixture A: first add methanol to the mixture A for precipitation to obtain a precipitate, then use deionized water to dissolve the precipitate, and then put it into a renewable fiber dialysis bag Dialyze in deionized water for 7 days, and finally take out the regenerated fiber dialysis bag and freeze-dry to obtain the esterified hydrophilic polymer; wherein, the freeze-drying conditions are: temperature: -60 degrees, pressure: 5pa;

[0038] (3) Dissolve the esterified hydrophilic polymer in PBS buffer at a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com