Fluorescent powder conversion type filament lamp for plant growth

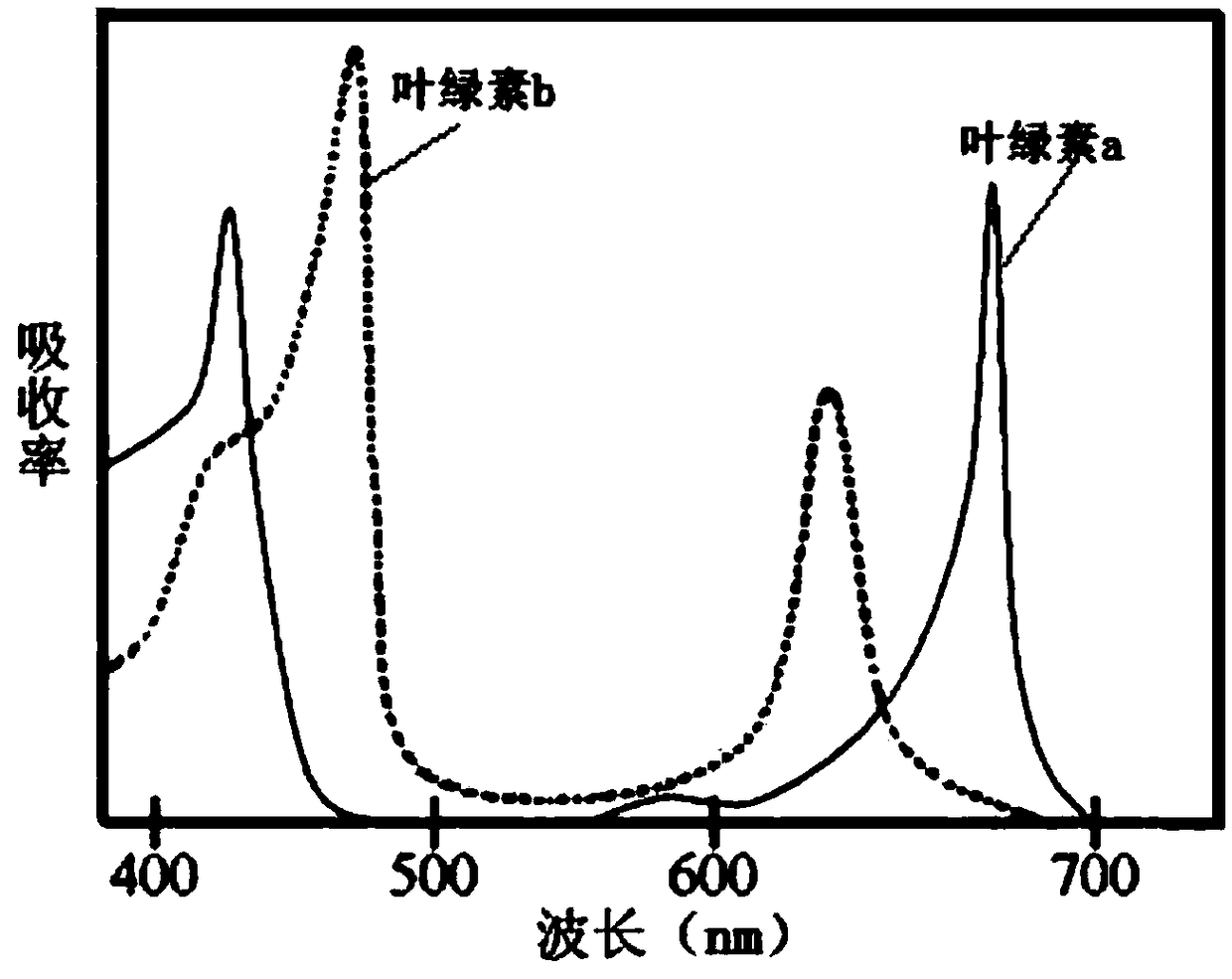

A plant growth and fluorescent powder technology, applied in the field of plant lighting, can solve the problems of poor thermal stability of light sources, high cost, single irradiation angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

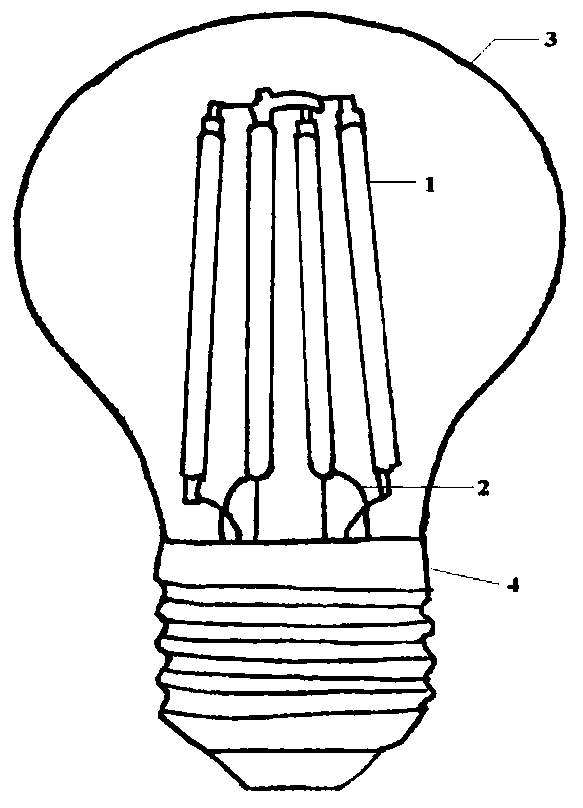

Method used

Image

Examples

Embodiment 1

[0108] Each of the above-mentioned fluorescent materials was tested for each optical characteristic parameter, and the data obtained from the test are shown in Table 1 and Table 2.

[0109] Table 1. Optical characteristic parameters of nitride red fluorescent materials

[0110]

[0111] Table 2. Optical characteristic parameters of yellow-green fluorescent materials

[0112]

Embodiment 2

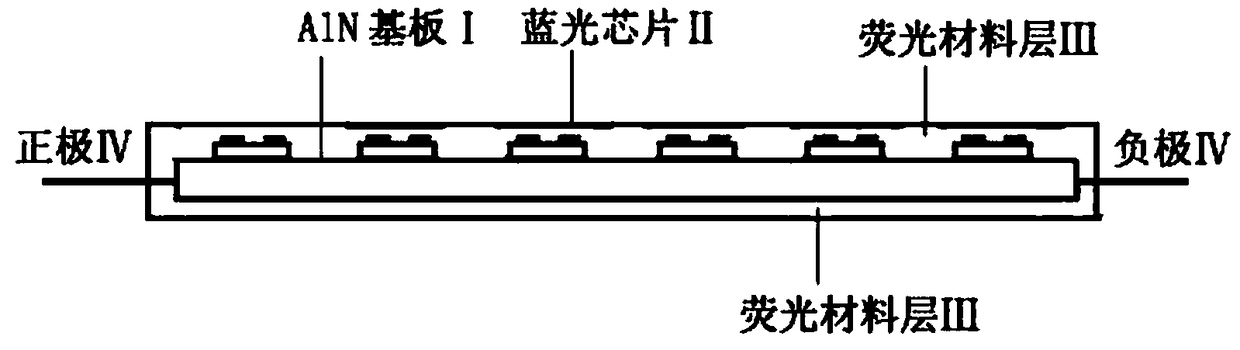

[0114] The light-emitting diode filament in the filament lamp for plant growth prepared in this embodiment includes an AlN substrate I, and a plurality of blue light chips II arranged on the AlN substrate I, the wavelength of the blue light chip II is 460nm; the molecular formula is (Ca 0.88 , Eu 0.12 ) 1.0525 Al 0.1 Si 2.2 N 3.7262 f 0.0264 The nitride red fluorescent material is mixed with silica gel according to the ratio of fluorescent material: silica gel = 4:1, and then covered on the blue chip II.

[0115] After testing, the emission spectrum of the obtained filament lamp for plant growth is as follows: Figure 4 Shown by the solid line a.

[0116] Depend on Figure 4 It can be seen that the emission spectrum of the filament lamp in this embodiment covers a wide band of 600nm to 800nm, the emission peak is located near 652nm, the half-peak width is 119.8nm, the luminous flux is as high as 244.5lm, and the corresponding color temperature (Tc) is about 1350K. The ...

Embodiment 3

[0119] The light-emitting diode filament in the filament lamp for plant growth prepared in this embodiment includes an AlN substrate I, and a plurality of blue light chips II arranged on the AlN substrate I, the wavelength of the blue light chip II is 460nm; the molecular formula is (Sr 0.85 , Eu 0.15 ) 1.0525 Al 0.1 Si 2.2 N 3.7262 f 0.0264 The nitride red fluorescent material is mixed with silica gel according to the ratio of fluorescent material: silica gel = 3.5:1, and then covered on the blue chip II.

[0120] After testing, the emission spectrum of the obtained filament lamp for plant growth is as follows: Figure 4 Shown by the dotted line b.

[0121] Depend on Figure 4 It can be seen that the emission spectrum of the filament lamp in this embodiment covers a wide band of 600nm-820nm, the emission peak is located near 663nm, the half-maximum width is 135nm, the luminous flux is as high as 100lm, and the corresponding color temperature (Tc) is about 1315K. The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission peak | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

| Luminous flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com