AlTiSiCON ultra-hard coating and preparation method thereof

A hard coating, coating technology, applied in coating, metal material coating process, ion implantation plating and other directions, to achieve the effect of improving corrosion resistance, high ionization rate and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An AlTiSiCON superhard coating in this embodiment is 3-4 μm thick and is suitable for drill bits and the like.

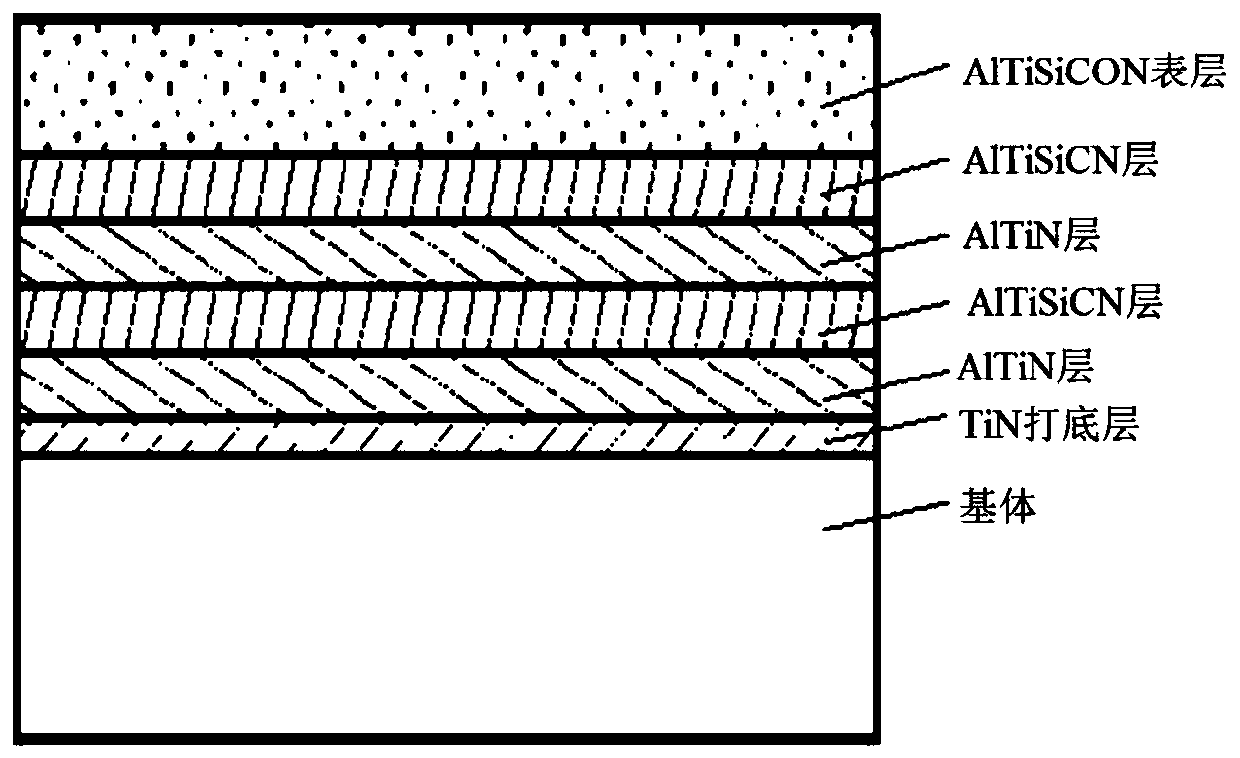

[0048] The coating is a multilayer structure, such as figure 1 As shown, it includes a TiN primer layer, an AlTiN layer, an AlTiSiCN layer, an AlTiN layer, an AlTiSiCN layer, and an AlTiSiCON surface layer from the inside to the outside. The AlTiN layer, AlTiSiCN layer, AlTiN layer, and AlTiSiCN layer between the TiN primer layer and the AlTiSiCON surface layer constitute an alternate layer of AlTiN and AlTiSiCN as a whole.

[0049] Among them, the thickness of the TiN primer layer is 0.1-0.2 μm; the thickness of the single-layer AlTiN layer in the interlaced layer of AlTiN and AlTiSiCN is 0.2-0.3 μm; the thickness of the single-layer AlTiSiCN layer in the interlaced layer of AlTiN and AlTiSiCN is 0.2-0.4 μm ; AlTiSiCON surface thickness of 1.0-2.5μm.

Embodiment 2

[0051] An AlTiSiCON superhard coating in this embodiment has a thickness of 1.5-3 μm and is suitable for milling cutters, gear hobbing cutters, stamping dies and the like.

[0052] The coating is a multilayer structure, such as figure 1 As shown, it includes a TiN primer layer, an AlTiN layer, an AlTiSiCN layer, an AlTiN layer, an AlTiSiCN layer, and an AlTiSiCON surface layer from the inside to the outside. The AlTiN layer, AlTiSiCN layer, AlTiN layer, and AlTiSiCN layer between the TiN primer layer and the AlTiSiCON surface layer constitute an alternate layer of AlTiN and AlTiSiCN as a whole.

[0053] Among them, the thickness of the TiN primer layer is 0.1-0.2 μm; the thickness of the single-layer AlTiN layer in the interlaced layer of AlTiN and AlTiSiCN is 0.15-0.2 μm; the thickness of the single-layer AlTiSiCN layer in the interlaced layer of AlTiN and AlTiSiCN is 0.15-0.3 μm ; AlTiSiCON surface thickness of 0.8-2.0μm.

Embodiment 3

[0055] An AlTiSiCON superhard coating in this embodiment is less than 1.5 μm thick and is suitable for taps with high precision requirements.

[0056] The coating is a multilayer structure, such as figure 1 As shown, it includes a TiN primer layer, an AlTiN layer, an AlTiSiCN layer, an AlTiN layer, an AlTiSiCN layer, and an AlTiSiCON surface layer from the inside to the outside. The AlTiN layer, AlTiSiCN layer, AlTiN layer, and AlTiSiCN layer between the TiN primer layer and the AlTiSiCON surface layer constitute alternate layers of AlTiN and AlTiSiCN.

[0057] Among them, the thickness of the TiN primer layer is 0.1-0.2 μm; the thickness of the single-layer AlTiN layer in the interlaced layer of AlTiN and AlTiSiCN is 0.1-0.15 μm; the thickness of the single-layer AlTiSiCN layer in the interlaced layer of AlTiN and AlTiSiCN is 0.1-0.2 μm ; AlTiSiCON surface thickness of 0.5-1.0μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com