A method of controlling the texture of vapor-deposited metal thin films by using semiconductor substrates

A metal thin film, vapor deposition technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems of complex process, instability, high cost of single crystal preparation, etc. tiny effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

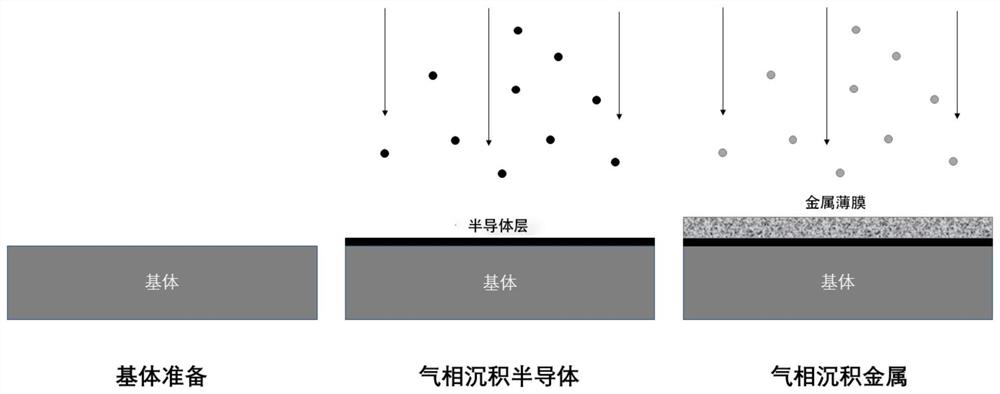

Method used

Image

Examples

Embodiment 1

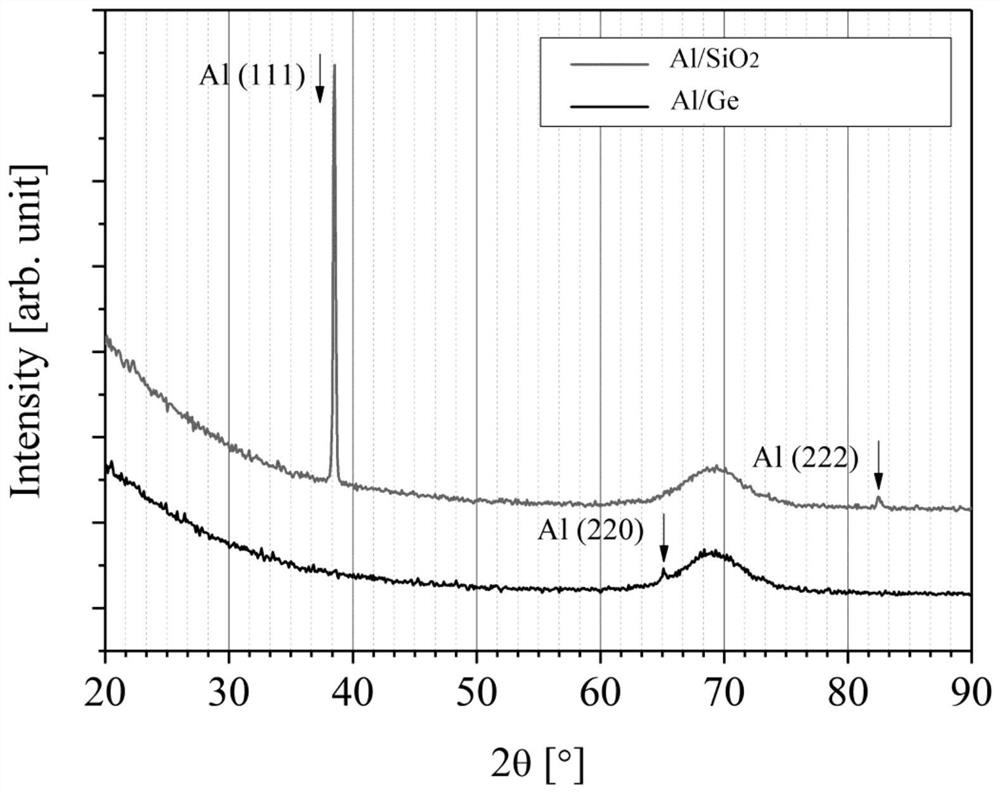

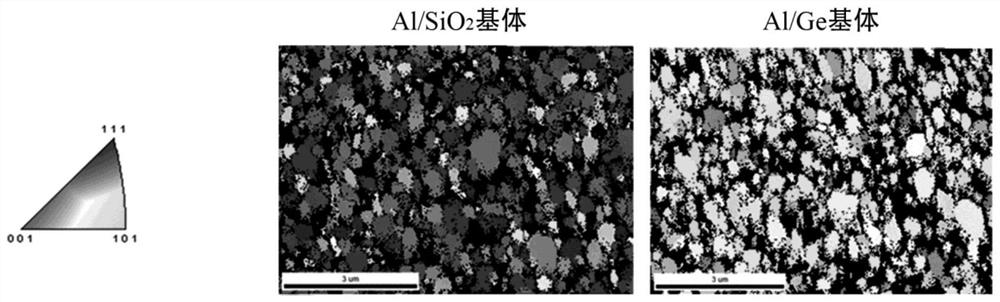

[0031] The metal Al thin film was vapor-deposited by Knudsen evaporation source by means of thermal evaporation. First prepare an inert SiO 2 The substrate of the oxide layer was cleaned with acetone and isopropanol in an ultrasonic cleaner, and then dried with pressurized nitrogen. The background vacuum of the vacuum chamber is 10 -8 Pa, the deposition temperature is room temperature. Next, a layer of Ge is thermally evaporated and deposited on the substrate in advance, with a deposition thickness of 1 nm. Finally, on the basis of the Ge substrate, continue to thermally evaporate the Al thin film, and the deposition thickness is 100nm.

[0032] Also using the thermal evaporation method, first prepare an inert SiO 2 The substrate of the oxide layer was cleaned with acetone and isopropanol in an ultrasonic cleaner, and then dried with pressurized nitrogen. The background vacuum of the vacuum chamber is 10 -8 Pa, the deposition temperature is room temperature. directly on...

Embodiment 2

[0035] The metal Al thin film was vapor-deposited by Knudsen evaporation source by means of thermal evaporation. First prepare an inert SiO 2 The substrate of the oxide layer was cleaned with acetone and isopropanol in an ultrasonic cleaner, and then dried with pressurized nitrogen. The background vacuum of the vacuum chamber is 10 -7 Pa, the deposition temperature is room temperature. Next, a layer of Ge is preliminarily thermally evaporated on the substrate with a deposition thickness of 10 nm. Finally, on the basis of the Ge substrate, continue to thermally evaporate the Al thin film, and the deposition thickness is 1000nm. The prepared Al / Ge film exhibits (110) texture.

Embodiment 3

[0037] The metal Al thin film was vapor-deposited by Knudsen evaporation source by means of thermal evaporation. First prepare an inert SiO 2 The substrate of the oxide layer was cleaned with acetone and isopropanol in an ultrasonic cleaner, and then dried with pressurized nitrogen. The background vacuum of the vacuum chamber is 5×10 -8 Pa, the deposition temperature is room temperature. Next, a layer of Ge is thermally evaporated and deposited on the substrate in advance, with a deposition thickness of 50 nm. Finally, on the basis of the Ge substrate, continue to thermally evaporate the Al thin film, and the deposition thickness is 500nm. The prepared Al / Ge film exhibits (110) texture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com