Low-rigidity TiNi alloy spring manufacturing technology

A preparation process and low rigidity technology, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of high production costs, achieve the effects of light weight, increased wire diameter, and stable and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

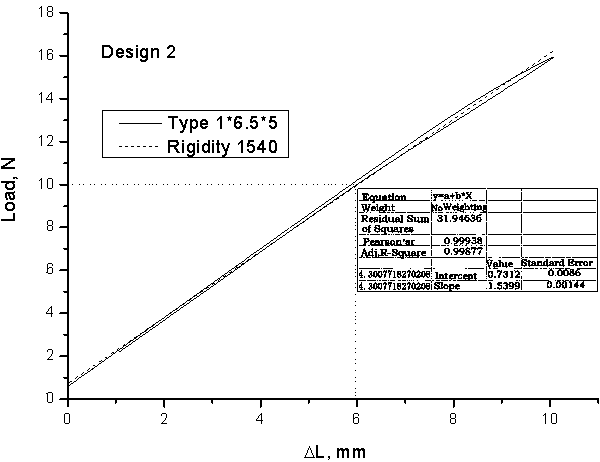

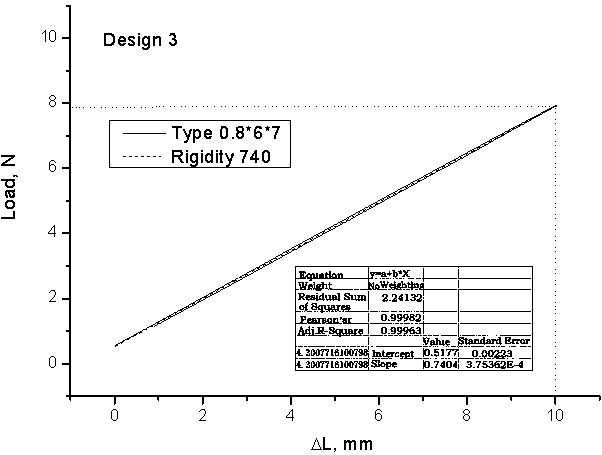

Image

Examples

Embodiment 1

[0029] A kind of preparation technology of low rigidity TiNi spring, its step is:

[0030] (1) Calculated and weighed according to mass percentage, the alloy composition is Ti: 44.2, Ni: 55.8, and the TiNi alloy ingot is prepared by vacuum induction melting in a cermet crucible to ensure the uniformity of the ingot composition and the control of impurity content;

[0031] (2) Put the TiNi alloy ingot into a resistance furnace, keep it warm for 1 hour at 850ºC, and after free forging, forge into a Φ40mm TiNi alloy forging rod.

[0032] (3) Put the TiNi alloy forged rod into a resistance furnace, heat it at 850ºC for 1 hour, and hot-roll it into a Φ8mm TiNi alloy rod;

[0033] (4) Put the Φ8mm TiNi alloy rod on the disc wire drawing machine, and perform hot drawing at 700°C, and draw it into a TiNi alloy wire with a diameter of 1.2mm;

[0034] (5) Cold draw the TiNi alloy wire with a diameter of 1.2mm until the final size is 1.0mm, cut two pieces of wire, number A and B respect...

Embodiment 2

[0040] A kind of preparation technology of low rigidity TiNi spring, its step is:

[0041] (1) Calculation and weighing according to mass percentage, the alloy composition is Ti: 45.2, Ni is 54.8, the TiNi alloy ingot is prepared by vacuum induction melting in a cermet crucible to ensure the uniformity of ingot composition and the control of impurity content;

[0042] (2) Put the TiNi alloy ingot into a resistance furnace, keep it warm for 1 hour at 900ºC, and after free forging, forge into a Φ40mm TiNi alloy forging rod.

[0043] (3) Put the TiNi alloy forged rod into a resistance furnace, heat it at 850ºC for 1 hour, and hot-roll it into a Φ8mm TiNi alloy rod;

[0044] (4) Put the Φ8mm TiNi alloy rod on the disc wire drawing machine, and perform hot drawing at 700°C, and draw it into a TiNi alloy wire with a diameter of 1.2mm;

[0045] (5) Cold draw the TiNi alloy wire with a diameter of 1.2mm until the final size is 0.8mm. Cut off two pieces of wire, numbered C and D respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com