A kind of solid phase microextraction fiber coating and its preparation method and application

A technology for extracting fibers and coatings, applied in the fields of analytical chemistry and environmental analysis, can solve the problems of low selectivity, expensive SPME, poor mechanical and thermal stability of coatings, etc., to reduce extraction steps and improve analysis. The effect of improving speed and extraction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation and application of embodiment 1 solid phase microextraction fiber coating

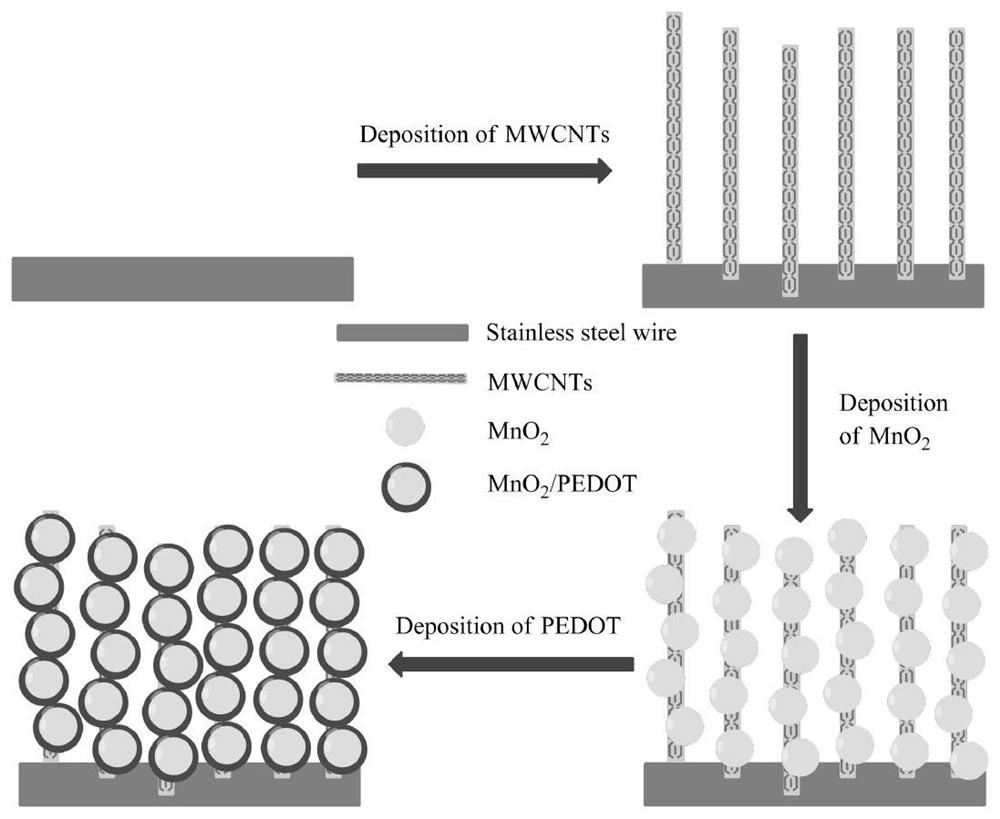

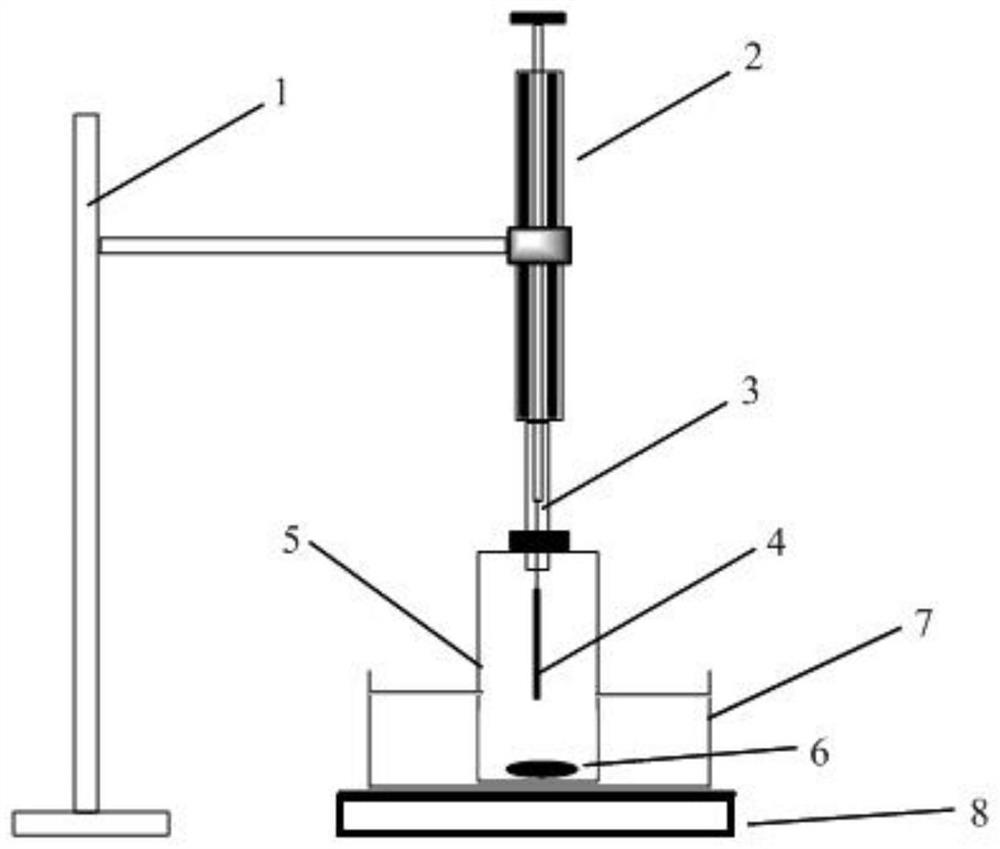

[0028] One, such as figure 1 Shown, the preparation method of the solid-phase microextraction fiber coating of the present embodiment is:

[0029] In the first step, multi-walled carbon nanotubes are deposited by the potentiostatic method. The specific method is as follows:

[0030] Weigh 0.0200g of multi-walled carbon nanotubes and 0.0150g of sodium lauryl sulfate in a 10mL beaker, add 10mL of ultrapure water, ultrasonicate for 15min, adopt a three-electrode system, use stainless steel wire as the working electrode, platinum electrode as the counter electrode, calomel The electrode was used as a reference electrode, deposited at a constant potential of -2.0V for 1000s, and then washed with water for 1h under magnetic stirring to obtain a multi-walled carbon nanotube coating.

[0031] In the second step, the multi-walled carbon nanotube / manganese dioxide binary composite coati...

experiment example 1

[0038] Thermogravimetric Analysis of Experimental Example 1 Solid Phase Microextraction Fiber Coating

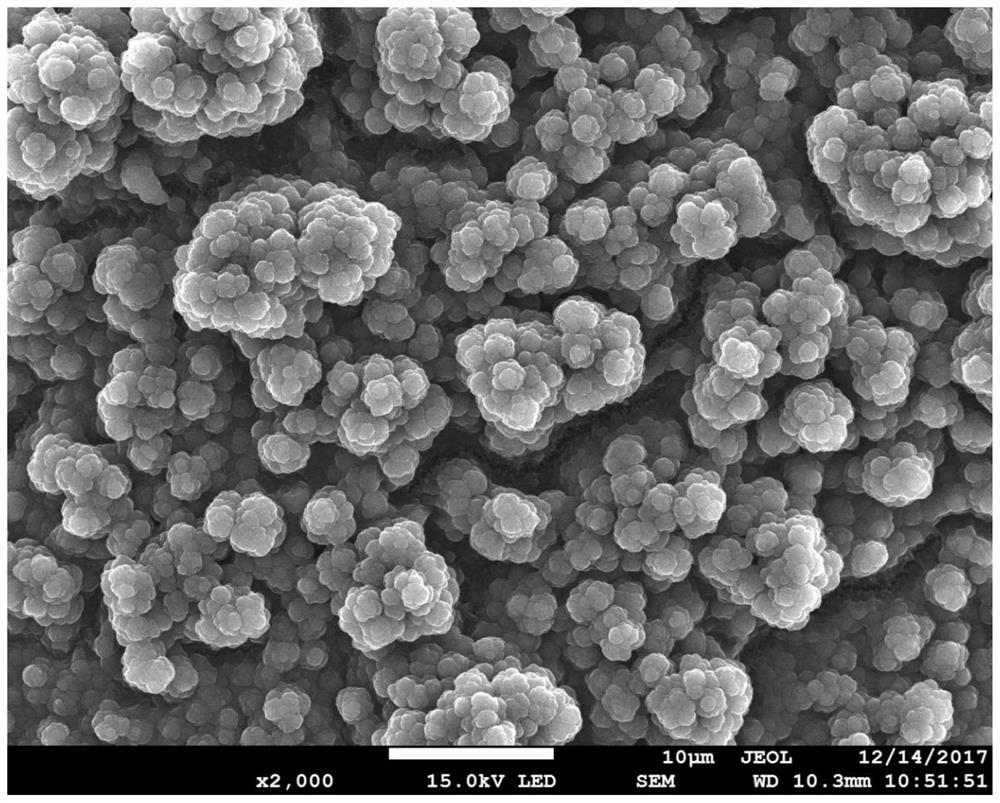

[0039] Thermogravimetric analysis (also known as thermogravimetric analysis or thermogravimetric analysis; Thermogravimetric analysis, TGA) is a method that changes the physical and chemical properties of substances with the increase of temperature (equal heating rate) or time (isothermal temperature and / or loss of mass conservation). . From Figure 4 The thermogravimetric analysis shows that the material begins to decompose after 300°C, so the thermal stability of the multi-walled carbon nanotube / manganese dioxide / poly3,4-ethylenedioxythiophene fiber coating at the desorption temperature of 280°C Good, suitable for solid phase microextraction process.

experiment example 2

[0040] Experimental Example 2 Extraction Effect Detection

[0041] 1. MWCNTs / MnO of the present invention 2 Determination of the linear range, detection limit, recovery rate and precision of PEDOT coating on polycyclic aromatic hydrocarbons

[0042] Under the optimized experimental conditions, the extraction time is 20min, the extraction temperature is 35°C, the stirring speed is 200r / min, the ionic strength is 0.3g / mL NaCl solution, and the desorption time is 3min. The linear range and detection limit are shown in Table 1 below. The comparison of phase microextraction methods is shown in Table 2.

[0043] Table 1 The linear range, detection limit, recovery rate and precision of polycyclic aromatic hydrocarbons in soil determined by micro-extraction device

[0044]

[0045] Table 2 This patent compares with other solid-phase microextraction methods

[0046]

[0047] It can be seen from the above table 1 that the detection limit is low (the detection limit reaches the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com