Surface compound treatment process of austenitic stainless steel welded joint

A technology of austenitic stainless steel and welded joints, applied in heat treatment furnaces, heat treatment equipment, metal material coating processes, etc., can solve problems such as uneven weld toe transition, large stress concentration, welded joint surface quality, simple process, etc., to achieve Effects of reduced surface roughness, improved stress corrosion resistance, and stress concentration relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

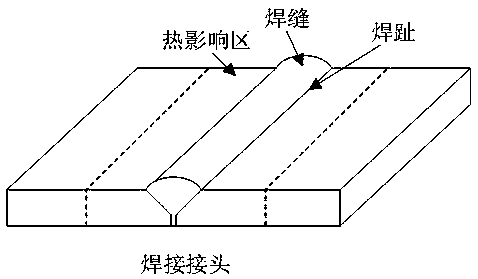

[0029] A surface composite treatment process for austenitic stainless steel welded joints, comprising the following steps:

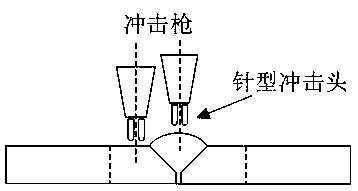

[0030] a. After the surface of the welded joint of the austenitic stainless steel part is cleaned, the heat-affected zone and the weld seam area of the joint are subjected to ultrasonic impact treatment under the first high-power working condition by using the impact gun first, and the needle-shaped impact head is used. The impact power of a high-power working condition is 0.8kW, the impact gun and the treatment surface form a first included angle, the angle of the first included angle is 60°, and the moving speed of the needle-shaped impact head is between 3cm / s;

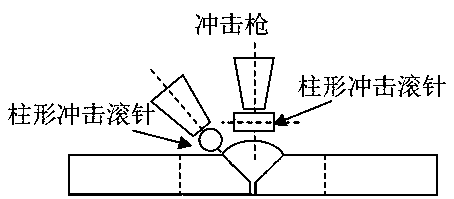

[0031] b. Then use an impact gun to use a cylindrical impact needle roller to perform ultrasonic impact treatment on the weld area and the weld toe area under the second high power condition. The second high power condition refers to a power of 1 kW to process the weld In the area, the axis...

Embodiment 2

[0036] A surface composite treatment process for austenitic stainless steel welded joints, comprising the following steps:

[0037] a. After the surface of the welded joint of the austenitic stainless steel part is cleaned, the heat-affected zone and the weld seam area of the joint are subjected to ultrasonic impact treatment under the first high-power working condition by using the impact gun first, and the needle-shaped impact head is used. The impact power of a high-power working condition is 1kW, the impact gun and the treatment surface form a first included angle, the angle of the first included angle is 90°, and the moving speed of the needle-shaped impact head is 5cm / s;

[0038] b. Then use an impact gun to use a cylindrical impact needle roller to perform ultrasonic impact treatment on the weld seam area and the weld toe area under the second high power working condition. The power of the second high power working condition is 1.2 kW to treat the weld seam In the are...

Embodiment 3

[0043] A surface composite treatment process for austenitic stainless steel welded joints, comprising the following steps:

[0044]a. After the surface of the welded joint of the austenitic stainless steel part is cleaned, the heat-affected zone and the weld seam area of the joint are subjected to ultrasonic impact treatment under the first high-power working condition by using the impact gun first, and the needle-shaped impact head is used. The impact power of a high-power working condition is 0.9kW, the impact gun and the treatment surface form a first included angle, the angle of the first included angle is 90°, and the moving speed of the needle-shaped impact head is 5cm / s;

[0045] b. Then use the impact gun to use the cylindrical impact needle roller to perform ultrasonic impact treatment on the weld seam area and the weld toe area under the second high power working condition. In the area, the axis of the cylindrical impact needle is perpendicular to the weld area, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com