Preparation method of nanometer porous carbon material

A nanoporous carbon and sodium bicarbonate technology, applied in the field of electrochemistry, can solve the problems of carbon particle microsphere micropore and small mesopore collapse, cumbersome process, and long time consumption, so as to improve hydrophilicity and hydrophobicity, and change hydrophilicity , to reduce the effect of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a nanoporous carbon material, comprising the steps of:

[0030] Step 1. Configure an aqueous solution containing a template agent (sodium dodecylbenzenesulfonate), and stir evenly until the template agent is completely dissolved, and the solution becomes clear with a concentration of 25.00×10 -3 mol / L;

[0031] Step 2: Add a certain amount of medicines phloroglucinol and melamine into the aqueous solution containing the templating agent, add formaldehyde after completely dissolving, then add the catalyst sodium bicarbonate solution, stir evenly, and form a sol, wherein the solute mass fraction is 20% , the molar ratio of phloroglucinol, melamine and formaldehyde is 4:1:10, the concentration of sodium bicarbonate solution is 0.05mol / L, and the molar ratio of phloroglucinol and sodium bicarbonate is 100;

[0032] Step 3, seal the sol and place it in an oven at 85°C, treat it for 5 days, cool to room temperature after gelation, take out the sample, ...

Embodiment 2

[0037] A method for preparing a nanoporous carbon material, comprising the steps of:

[0038] Step 1. At 35°C, configure an aqueous solution containing a template agent (hexadecyltrimethylammonium bromide), and stir evenly until the template agent is completely dissolved, and the solution becomes clear with a concentration of 25.00×10 -3 mol / L.

[0039] Step 2: Add a certain amount of medicines phloroglucinol and melamine into the aqueous solution containing the templating agent, add formaldehyde after completely dissolving, then add the catalyst sodium bicarbonate solution, stir evenly, and form a sol, wherein the solute mass fraction is 20% , the molar ratio of phloroglucinol, melamine and formaldehyde is 3:2:10, the concentration of sodium bicarbonate solution is 0.05mol / L, and the molar ratio of phloroglucinol and sodium bicarbonate is 50;

[0040] Step 3, seal the sol and place it in an oven at 85°C, treat it for 5 days, cool to room temperature after gelation, take out ...

Embodiment 3

[0045] A method for preparing a nanoporous carbon material, comprising the steps of:

[0046] Step 1. At 35°C, configure an aqueous solution containing a template agent (sodium dodecylbenzenesulfonate), and stir evenly until the template agent is completely dissolved, and the solution becomes clear with a concentration of 15.00×10 -3 mol / L.

[0047] Step 2: Add a certain amount of medicines phloroglucinol and melamine into the aqueous solution containing the templating agent, add formaldehyde after completely dissolving, then add the catalyst sodium bicarbonate solution, stir evenly, and form a sol, wherein the solute mass fraction is 10% , the molar ratio of phloroglucinol, melamine and formaldehyde is 3:2:10, the concentration of sodium bicarbonate solution is 0.05mol / L, and the molar ratio of phloroglucinol and sodium bicarbonate is 50;

[0048] Step 3, seal the sol and place it in an oven at 85°C, treat it for 5 days, cool to room temperature after gelation, take out the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

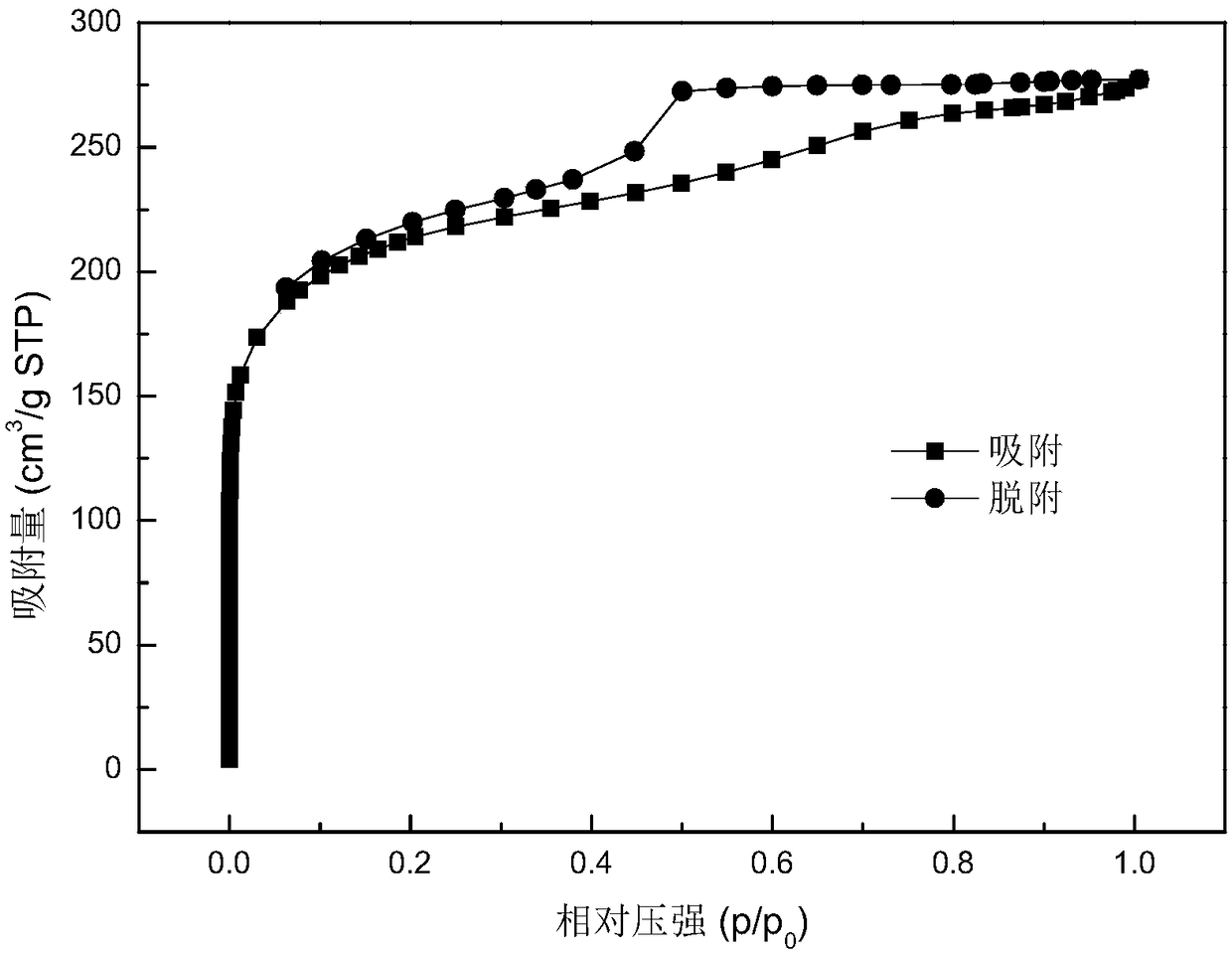

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com