Microwave-assisted production method of aerogel and methylsilsesquioxane aerogel

A microwave-assisted, production method technology, applied in the field of methyl silsesquioxane airgel, can solve the problems of reducing drying time, etc., and achieve the effects of reduced production time, excellent performance and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A microwave-assisted production method of methylsilsesquioxane airgel, comprising the following steps:

[0032] 1) Add the template agent dodecyltrimethylammonium chloride to the hydrochloric acid solution; then add methyltrimethoxysilane and dimethyldimethoxysilane as precursors, the volume ratio of the precursors is 1:2, after magnetic stirring for 30 minutes under airtight conditions, add 0.8 mL propylene oxide gel accelerator to the solvent at the ratio of 0.8 mL per 5 mL of solvent, stir again and put it into a microwave device for gelation and aging; The time for gelation and aging is 15 minutes, and the microwave frequency is 500 W;

[0033] 2) The gel formed in step 1) was replaced by isopropanol solvent under the assistance of microwave to obtain the gel after sol replacement; the number of solvent replacement was 2 times, the microwave-assisted replacement time was 3-5 min, and the microwave frequency was 500W;

[0034] 3) Place the gel after solvent replace...

Embodiment 2

[0039] A microwave-assisted production method of methylsilsesquioxane airgel, comprising the following steps:

[0040] 1) Add the template agent dodecyltrimethylammonium chloride to the mixed solution of hydrochloric acid and methanol, then add methyltrimethoxysilane as the precursor, the volume ratio of the precursor is 1:2, After magnetic stirring for 30 min under airtight conditions, add 1 mL of propylene oxide gel accelerator into the solvent according to the ratio of 1 mL of propylene oxide gel accelerator for every 6 mL of solvent, stir again and put it into microwave for gelation and aging; gelation, aging The time is 10 min, and the microwave frequency is 750 W;

[0041] 2) The gel formed in step 1) was replaced by isopropanol solvent under the assistance of microwave to obtain the gel after sol replacement; the number of solvent replacement was 2 times, the microwave-assisted replacement time was 3-5 min, and the microwave frequency was 750W;

[0042] 3) Place the g...

Embodiment 3

[0047] A microwave-assisted production method of methylsilsesquioxane airgel, comprising the following steps:

[0048] 1) Add the template agent dodecyltrimethylammonium chloride to the mixed solution of acetic acid and methanol; then add methyltriethoxysilane as a precursor, the volume ratio of the precursor is 1:2 ; After magnetically stirring for 30 min under airtight conditions, add 1.5 mL of propylene oxide gel accelerator to the solvent at a ratio of 1.5 mL per 8 mL of solvent, stir again and put it in a 40°C oven for gelation and aging for 1.5 hours.

[0049] 2) The gel formed in step 1) was replaced by methanol solvent twice in an oven at 40°C, 8~24h / time, and then replaced by isopropanol and n-heptane at 60°C for 2~3 times, 8~ 24 h / time.

[0050] 3) The gel after solvent replacement was placed in a microwave drying equipment for microwave drying, the drying time was 30 min, and the microwave frequency was 500 W.

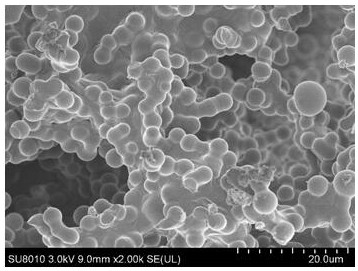

[0051] Figure 5 It is a scanning electron microgra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com