Multifunctional low surface treatment epoxy thick build long-acting anticorrosion primer and preparation method thereof

A technology of low surface treatment and epoxy thick paste, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of low environmental protection performance of primers, achieve excellent anti-rust ability, improve adhesion and impact strength , the effect of excellent diffusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

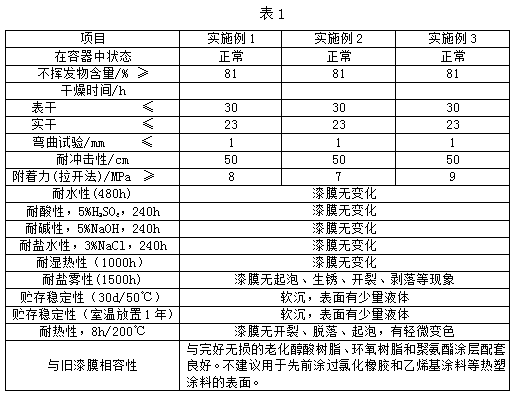

Examples

Embodiment 1

[0038] Prepare component A:

[0039] Step 1. Add 2kg of tannic acid into a small pot, pour 2kg of absolute ethanol, and disperse at 200-300r / min for 1-2 minutes to fully activate the tannic acid;

[0040] Step 2. Add 12kg of bisphenol A low molecular weight 618 epoxy resin into the basket dispersion basin, add 0.6kg of A400 wetting and dispersing agent at a speed of 500-800r / min, and continue stirring for 2-4 minutes; Next, add 0.3kg VP031 wax, 8kg zinc phosphate, 13kg aluminum tripolyphosphate, 4kg activated tannic acid, 3kg polysilicon auxiliary agent MP-3 and 2kg propylene oxide butyl ether, stir thoroughly for 8-15min to obtain a paint pulp.

[0041] Step 3. The paint slurry is ground by a basket grinding method at a rotating speed of 500-800 r / min, and ground for 3-4 hours until the fineness is ≤60 µm.

[0042] Step 4. Add 8kg of bisphenol A type medium and high molecular weight 604 epoxy resin into the high stirring dispersion basin, add 3kg of butanol, 5kg of low vola...

Embodiment 2

[0048] Prepare component A:

[0049] Step 1. Add 3kg of tannic acid into a small pot, pour 3kg of absolute ethanol, and disperse at 200-300r / min for 1-2 minutes to fully activate the tannic acid;

[0050] Step 2. Add 10kg of bisphenol A low molecular weight 618 epoxy resin into the basket dispersion basin, add 0.6kg of wetting and dispersing agent A400S at a speed of 500-800r / min, and continue stirring for 2-4 minutes; Next, add 0.2kg VP031 wax, 12kg zinc phosphate, 14kg aluminum tripolyphosphate, 6kg activated tannic acid, 4kg polysilicon auxiliary agent MP-3 and 3kg aliphatic glycidyl ether, stir thoroughly for 8-15min to obtain paint paste .

[0051] Step 3. The paint slurry is ground by a basket grinding method at a rotating speed of 500-800 r / min, and ground for 3-4 hours until the fineness is ≤60 µm.

[0052] Step 4. Add 6kg of bisphenol A type medium and high molecular weight 609 epoxy resin into the high-stirring dispersion basin, add 2kg of butanol, 4kg of low volat...

Embodiment 3

[0058] Prepare component A:

[0059] Step 1. Add 2kg of tannic acid into a small pot, pour 2kg of absolute ethanol, and disperse at 200-300r / min for 1-2 minutes to fully activate the tannic acid;

[0060] Step 2. Add 15kg of bisphenol A low molecular weight 618 epoxy resin into the basket dispersion basin, add 0.4kg of wetting and dispersing agent AT204 at a speed of 500-800r / min, and continue stirring for 2-4 minutes; Next, add 0.3kg VP031 wax, 6kg zinc phosphate, 9kg aluminum tripolyphosphate, 4kg activated tannic acid, 2kg polysilicon auxiliary agent MP-3 and 1kg propylene oxide butyl ether, stir thoroughly for 8-15min to obtain a paint pulp.

[0061] Step 3. The paint slurry is ground by a basket grinding method at a rotating speed of 500-800 r / min, and ground for 3-4 hours until the fineness is ≤60 µm.

[0062] Step 4. Add 5kg of bisphenol A medium and high molecular weight 604 epoxy resin and 5kg of 609 epoxy resin into the high stirring dispersion basin respectively, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com