Thermal stable sodium niobate-based lead-free piezoelectric ceramic and preparation method thereof

A technology based on lead-free piezoelectric and sodium niobate, which is applied in the field of functional ceramic materials, can solve the problems of insufficient industrial application, insufficient temperature stability of piezoelectric and electromechanical coupling performance of potassium sodium niobate system, and influence on the surface of thick film process ceramics Quality and other issues, to achieve the effect of reducing the sintering temperature and improving the piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] a. Raw material: 5.6280g Na 2 CO 3 , 2.3681g BaCO 3 , 0.4429g SrCO 3 , 13.9550g Nb 2 o 5 , 0.9585gTiO 2 , 0.3697g ZrO 2

[0031] b. The above-mentioned prepared raw materials are mixed with alcohol as a medium by ball milling for 6 hours; the wet powder is dried to obtain a mixed powder;

[0032] c. Place the obtained mixed powder in an alumina crucible for calcination and synthesis at a synthesis temperature of 900 o C, heat preservation for 4 hours; repeat the ball mill mixing and calcination process once to complete the pre-calcination synthesis;

[0033] d. After the pre-synthesized powder is ground, it is still ball-milled with alcohol as the medium for 12 hours. After the dried powder passes through a 100-mesh sieve, it is cold-pressed under a pressure of 100 MPa to form a circle with a diameter of 10 mm and a thickness of 1 mm. sheet to obtain a ceramic green body;

[0034] e. The obtained ceramic green body is sintered in the air under normal pressure ...

Embodiment 2

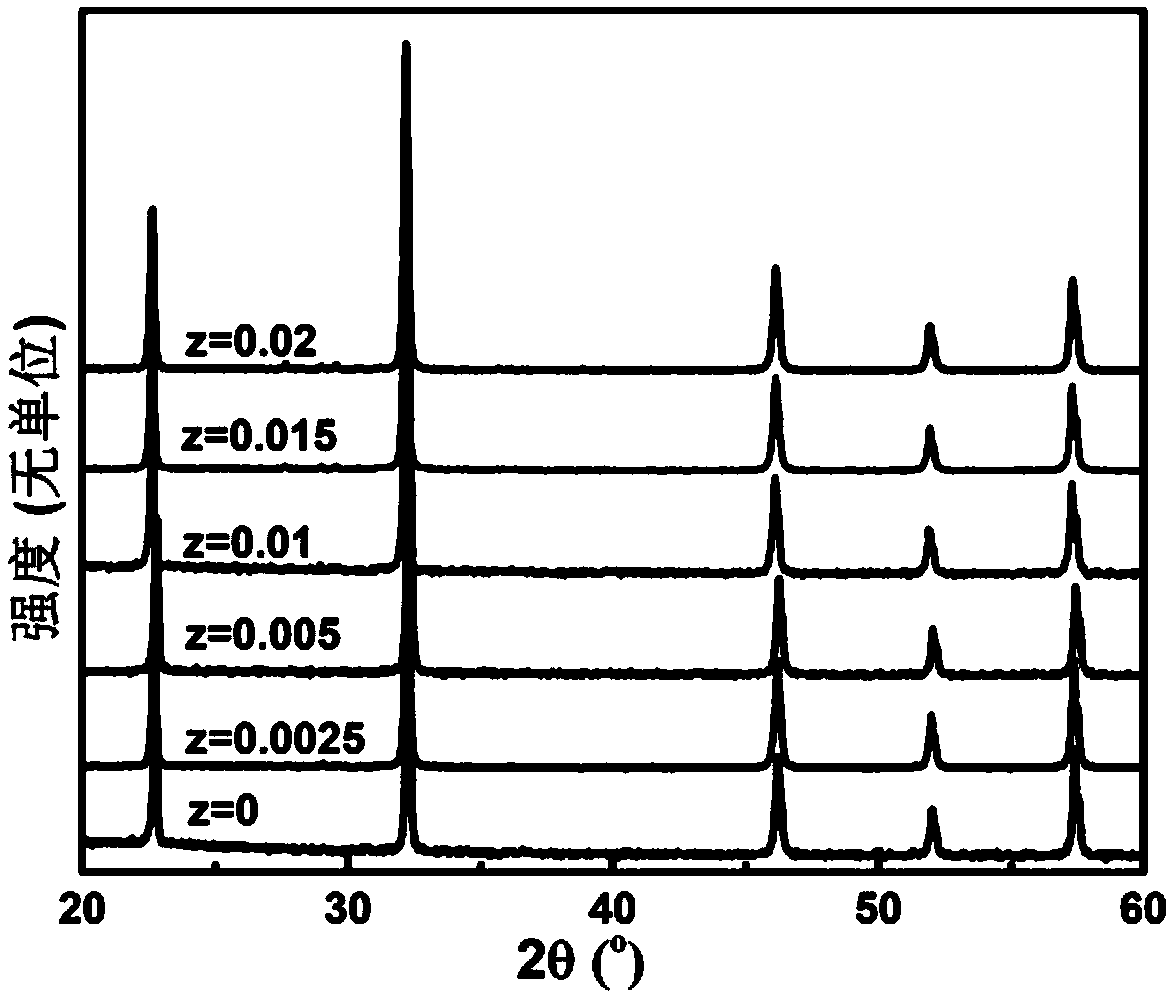

[0039] Carry out each step sequentially according to the above-mentioned embodiment mode, wherein adopt (1-z)[0.8625NaNbO 3 +0.1BaTiO 3 +0.0375SrZrO 3 ]+zCuO is composed of piezoelectric ceramics, the pre-calcination temperature is 900 o C. The time is 4 hours. After two calcinations, ball mill again for 24 hours with absolute ethanol as the ball milling medium. Then the formed green body is at 1200-1300 o C in the range of sintering for 2 hours. The X-ray diffraction pattern of the sample when z=0, 0.0025, 0.005, 0.01, 0.015 and 0.02 is as follows Figure 4 shown.

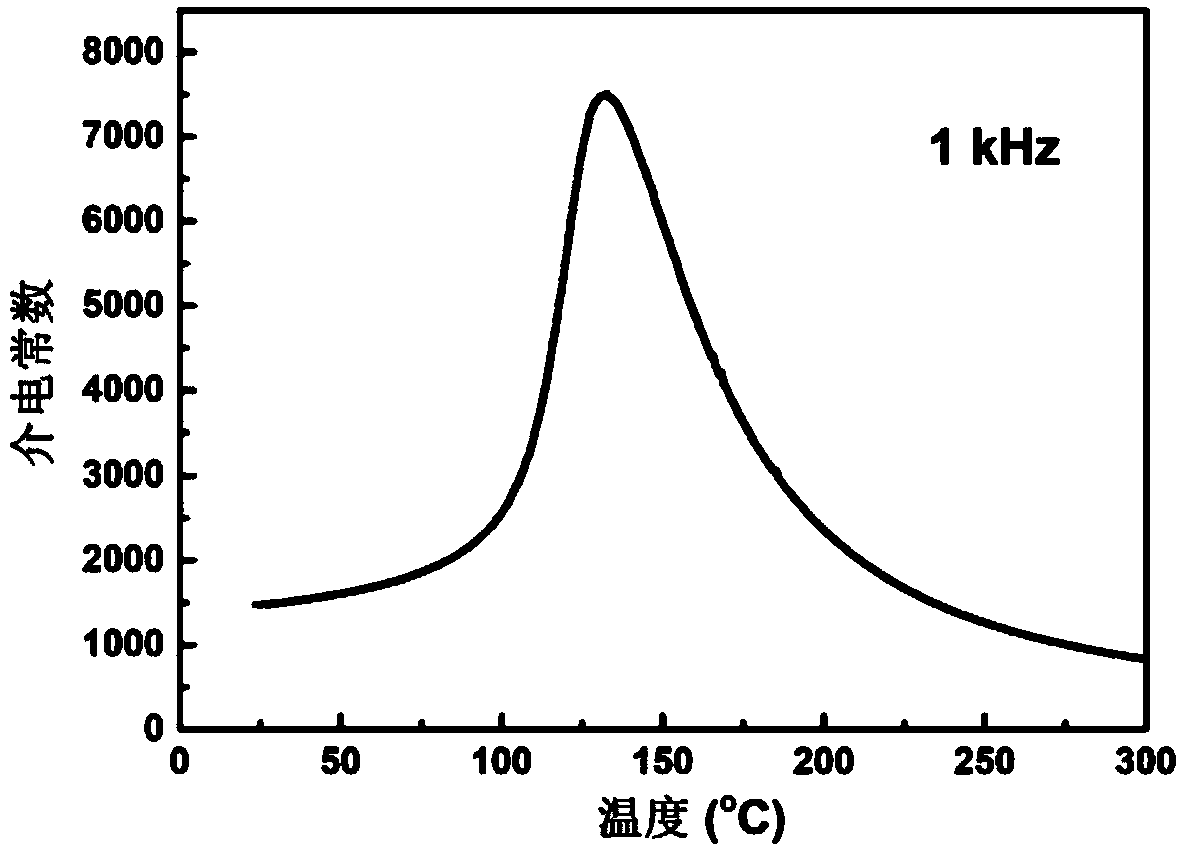

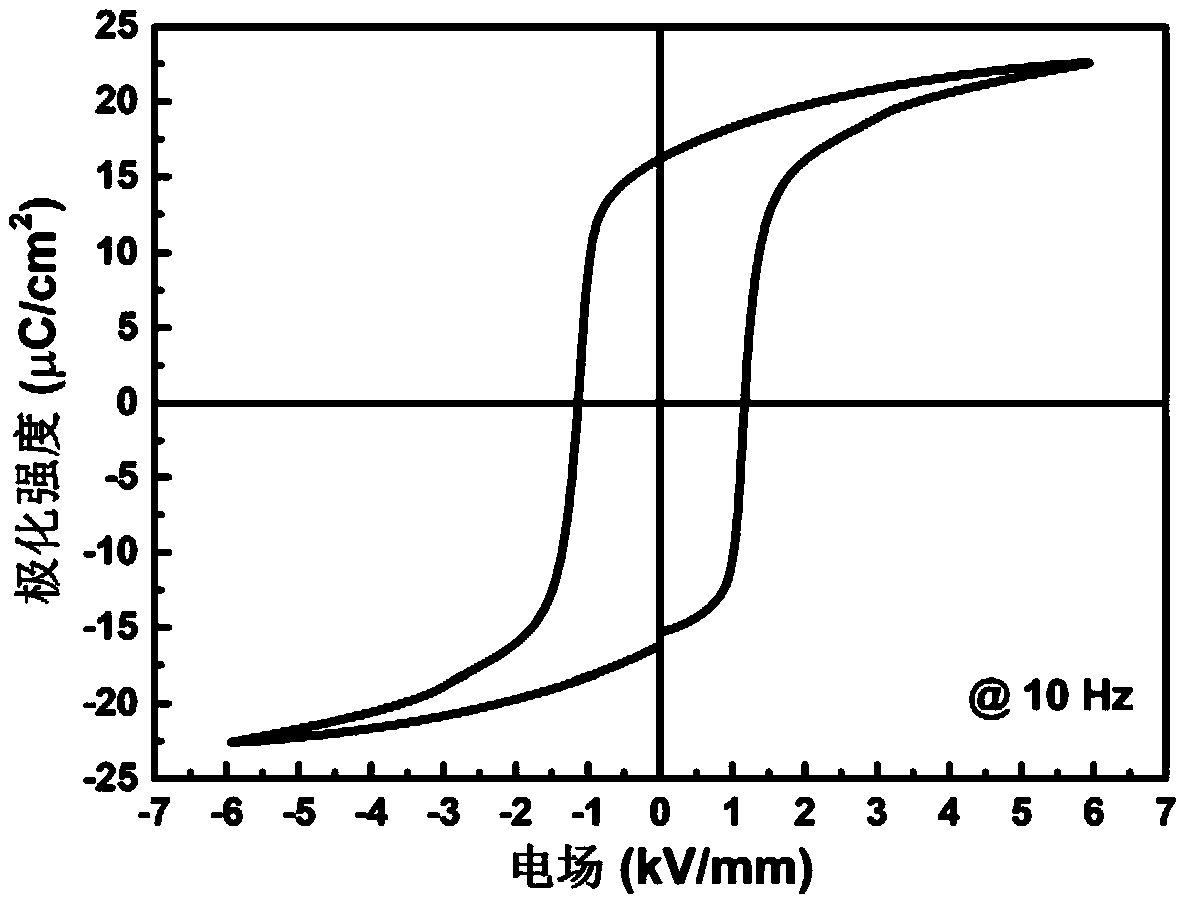

[0040] Sample at 1250 when z=0.005 o The scanning electron micrographs of the natural surface after sintering at C for 2 hours are as follows Figure 5 As shown, the morphology of the grains is spherical. Other physical properties of the measured sample: the Curie temperature is 83 o C, the dielectric constant is 2800 (1kHz), the piezoelectric constant is 270 pC / N, the planar electromechanical coupling c...

Embodiment 3

[0042] a. Raw material: 5.5962g Na 2 CO 3 , 3.0785g BaCO 3 , 13.8753g Nb 2 o 5 , 0.9585g TiO 2 , 0.4436gZrO 2

[0043] b. The above-mentioned prepared raw materials are mixed with alcohol as a medium by ball milling for 6 hours; the wet powder is dried to obtain a mixed powder;

[0044] c. Place the obtained mixed powder in an alumina crucible for calcination and synthesis at a synthesis temperature of 900 o C, heat preservation for 4 hours; repeat the ball mill mixing and calcination process once to complete the pre-calcination synthesis;

[0045] d. After grinding the obtained pre-synthesized powder, still use alcohol as the medium to ball mill for 12 hours. After the dried powder passes through a 100-mesh sieve, it is cold-pressed under a pressure of 100 MPa to form a circle with a diameter of 10 mm and a thickness of 1 mm. sheet to obtain a ceramic green body;

[0046] e. The obtained ceramic green body is sintered in the air under normal pressure using the buried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com