Solar cell and manufacturing process thereof

A solar cell and manufacturing process technology, applied in the field of solar cells, can solve problems affecting the improvement of photoelectric conversion efficiency, etc., and achieve the effect of high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

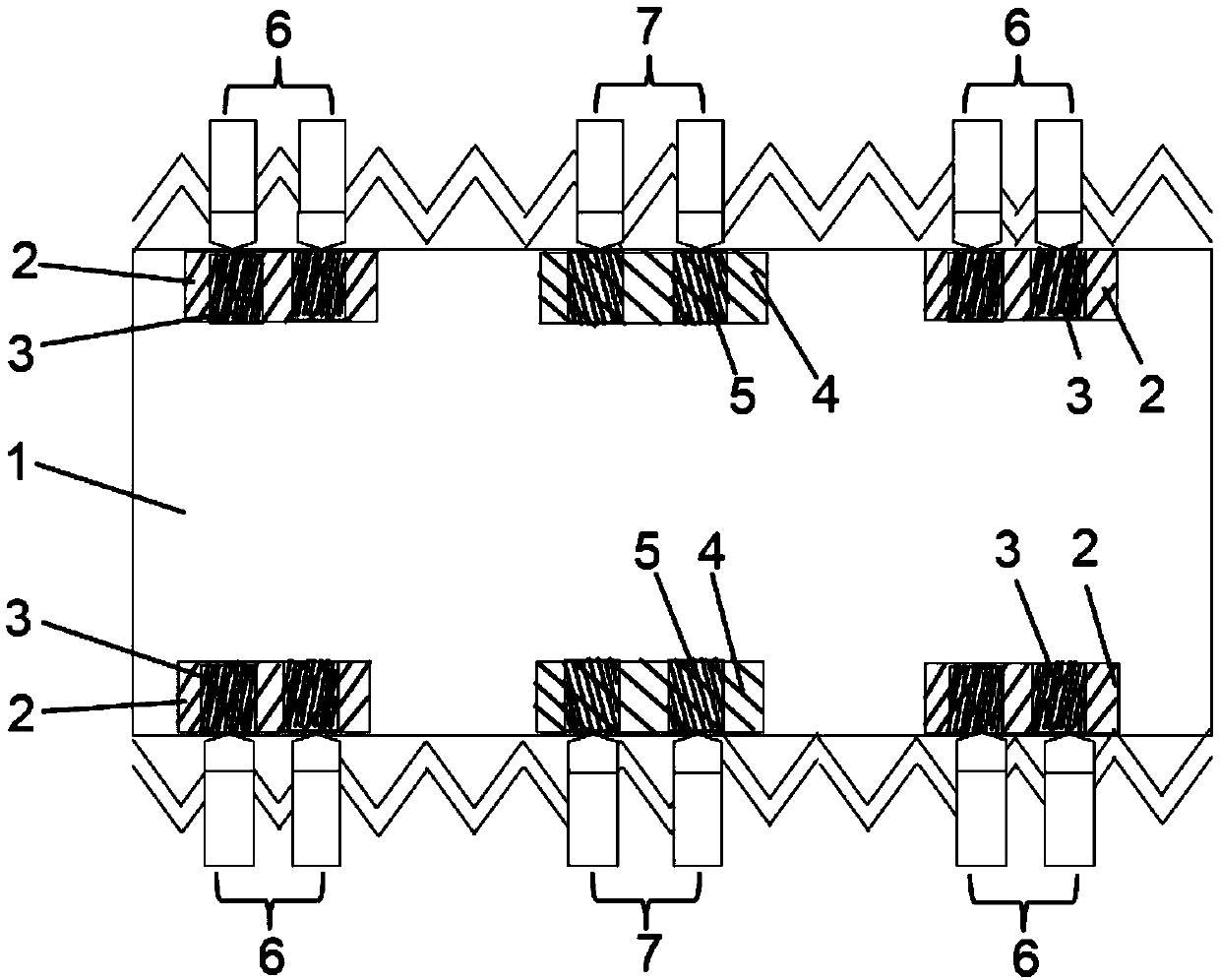

[0043] Prepare a solar cell with a double-sided symmetrical emitter junction structure:

[0044] (1) Alkali texturing of silicon wafers: cleaning of N-type monocrystalline silicon wafers to remove the damaged layer on the surface of the silicon wafers, followed by alkali texturing, the lye used is according to KOH: additive: H2O=8:1.5 : The KOH solution prepared in the ratio of 160, the concentration of the KOH solution is 5%, the temperature is 80° C., and a pyramid structure suede is formed on both sides of the silicon wafer;

[0045] (2) Form symmetrical p+ regions on both sides of the battery: First, use boron tribromide as the boron source in the boron diffusion furnace to perform single-sided boron diffusion. Wax to prepare mask, and then pass through HF / HNO in single-side etching equipment 3 The solution etches away the boron in the area not covered by the mask, thereby forming a p+ region in the covered area. The p+ region is located on the left and right sides of bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com