A kind of bulletproof composite material and its preparation method and application

A bulletproof composite material and a technology of the composite material, which are applied in the field of bulletproof composite materials and their preparation, can solve the problems affecting the ballistic resistance, poor light resistance, heavy weight of bulletproof armor, etc., and achieve good high and low temperature resistance, strong wearing comfort, extremely The effect of good thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

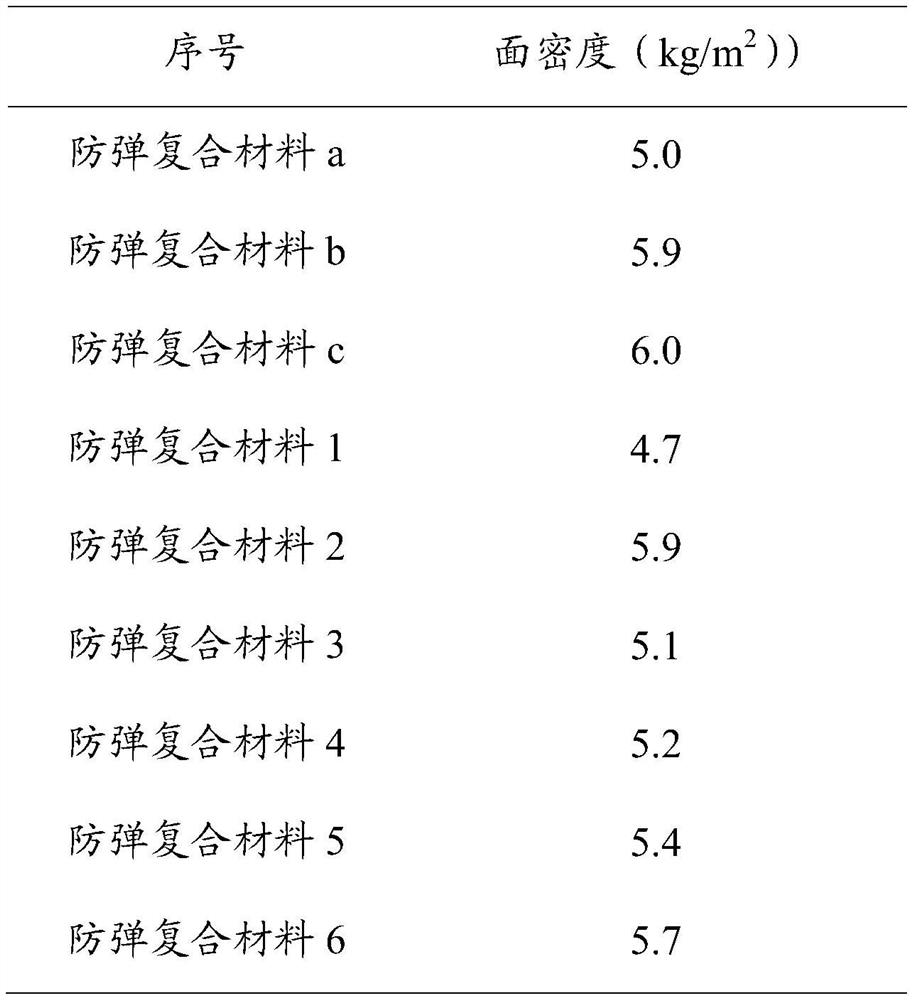

Examples

Embodiment 1

[0029] Preparation of a bulletproof composite material:

[0030] 1) After weighing 75g of water-based thermoplastic polyurethane and 75g of water-based polyolefin resin and mixing them uniformly, dilute with water to form a stable uniform emulsion, and then evenly coat the mixed emulsion on the surface of the reinforced polyimide fiber. After the water evaporates, Obtain modified polyimide fiber 1;

[0031] 2) Arranging the modified polyimide fibers 1 in parallel in one direction to form a fiber layer 1 arranged in parallel in one direction;

[0032] 3) Soak the fiber layer 1 in polyurethane resin to make a prepreg 1 with fibers arranged in parallel in one direction, and then place two layers of prepreg 1 with fibers arranged in parallel in one direction according to the fiber axis of 0° / 90° The angle of rotation is cross-laminated, and the bulletproof composite material 1 is compounded by a composite machine.

Embodiment 2

[0034] Preparation of a bulletproof composite material:

[0035] 1) Weigh 125g of water-based thermoplastic polyurethane and 25g of water-based polyolefin resin and mix them uniformly, dilute with water to form a stable uniform emulsion, and then evenly coat the mixed emulsion on the surface of the reinforced polyimide fiber. After the water evaporates, Obtain modified polyimide fiber 2;

[0036] 2) Arranging the modified polyimide fibers 2 in parallel in one direction to form a fiber layer 2 arranged in parallel in one direction;

[0037] 3) Soak the fiber layer 2 in polyurethane resin to make a prepreg 2 with fibers arranged in parallel in one direction, and then place four layers of prepreg 2 with fibers arranged in parallel in one direction at 0° / 45° / 90° / 135° fiber axis rotation angle for cross-lamination, compounded by a composite machine to make a bulletproof composite material 2.

Embodiment 3

[0039] Preparation of a bulletproof composite material:

[0040] 1) Weigh 25g of water-based thermoplastic polyurethane and 125g of water-based polyolefin resin and mix them uniformly, dilute with water to form a stable uniform emulsion, and then evenly coat the mixed emulsion on the surface of the reinforced polyimide fiber. After the water evaporates, Obtain modified polyimide fiber 3;

[0041] 2) Arranging the modified polyimide fibers 3 in parallel in one direction to form a fiber layer 3 arranged in parallel in one direction;

[0042] 3) Soak the fiber layer 3 in epoxy resin to make a prepreg 3 with fibers arranged in parallel in one direction, and then place two layers of prepreg 3 with fibers arranged in parallel in one direction according to 0° / 90° fibers Cross-lamination is carried out according to the rotation angle of the shaft, and the bulletproof composite material 3 is compounded by a composite machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com