Metal-organic framework material for separating ethylene and acetylene, and method for separating ethylene and acetylene

A metal-organic framework and ethylene technology, which is applied in the preparation of metal-organic framework materials and the separation of alkenes and alkynes, can solve the problems of expensive ligands, a large amount of organic waste liquid, and high preparation costs, and achieve adsorption and separation options. Good performance, high adsorption selectivity, and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

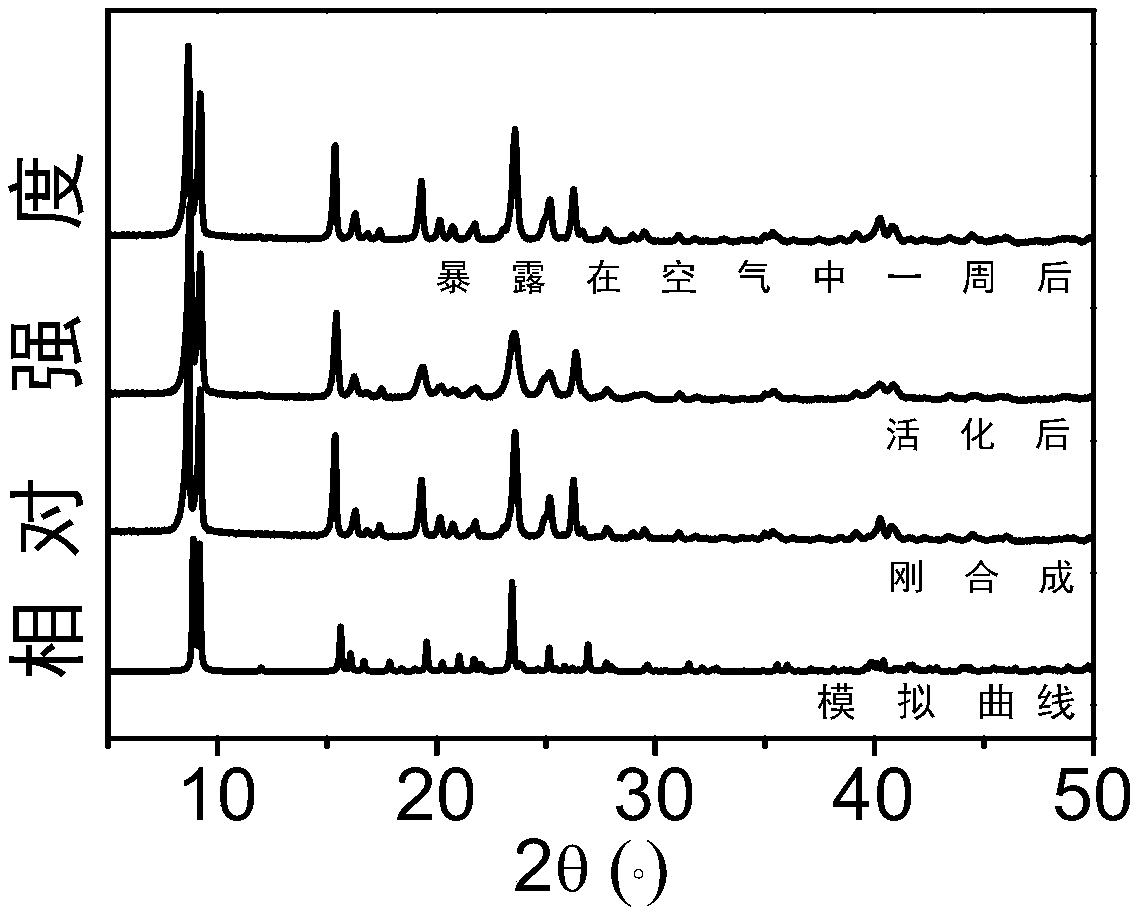

[0044] Add the aqueous solution containing 1mmol pyrazine-2,3-dicarboxylic acid and 2mmol sodium hydroxide dropwise to the aqueous solution containing 1mmol copper perchlorate hexahydrate and 12.5mmol pyrazine for reaction at room temperature, and the solids obtained in the reaction are successively watered Washing and methanol washing several times to obtain the purified metal-organic framework material, the XRD characterization data of the material structure is shown in the appendix figure 1 . The purified adsorbent was vacuum degassed at 120 °C for 12 hours to obtain the desolvated adsorbent, followed by gas adsorption.

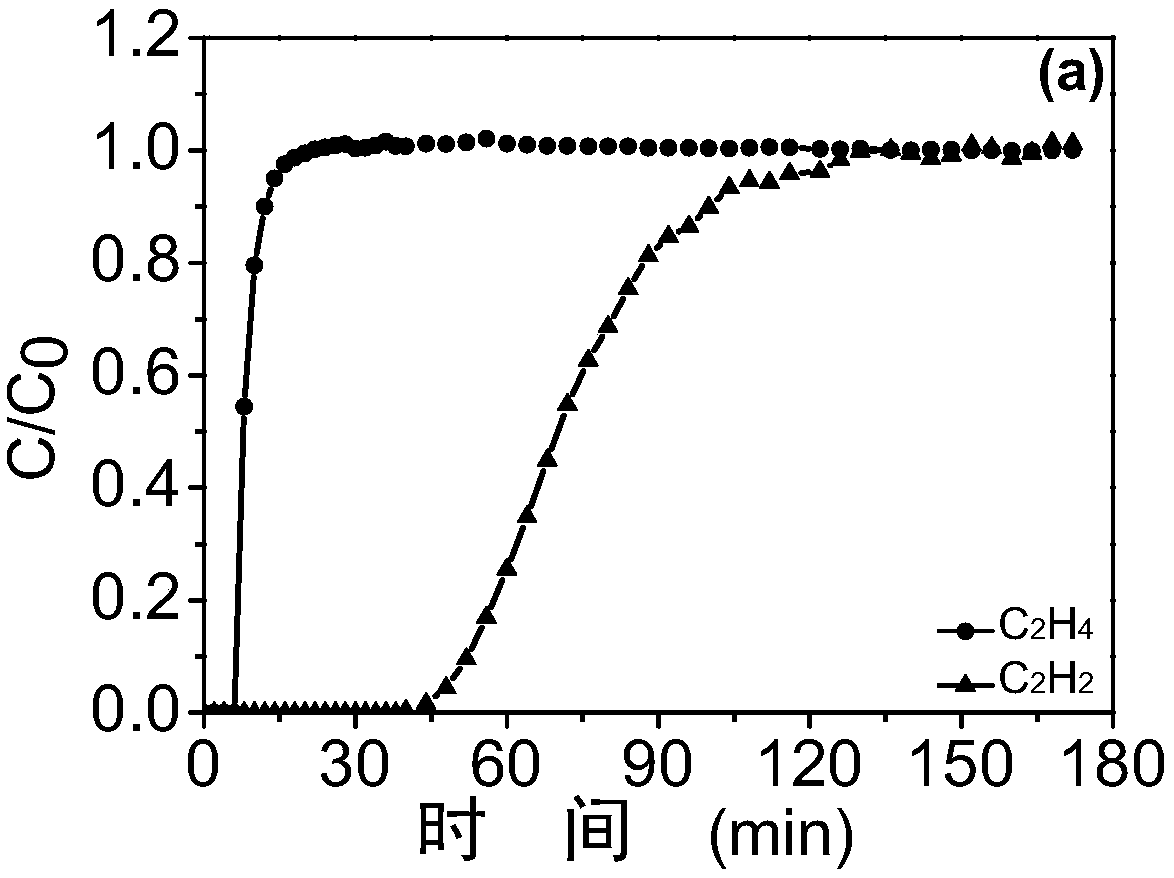

[0045] To test the adsorption-separation performance of the above-synthesized MOFs, a single-component adsorption isotherm of ethylene acetylene was carried out using the above-mentioned adsorbents. Take 100mg of adsorbent and set the adsorption temperature to 0°C. After testing, at 25°C and 1 bar, the adsorption capacity of acetylene reaches 2.08mmol / g,...

Embodiment 2

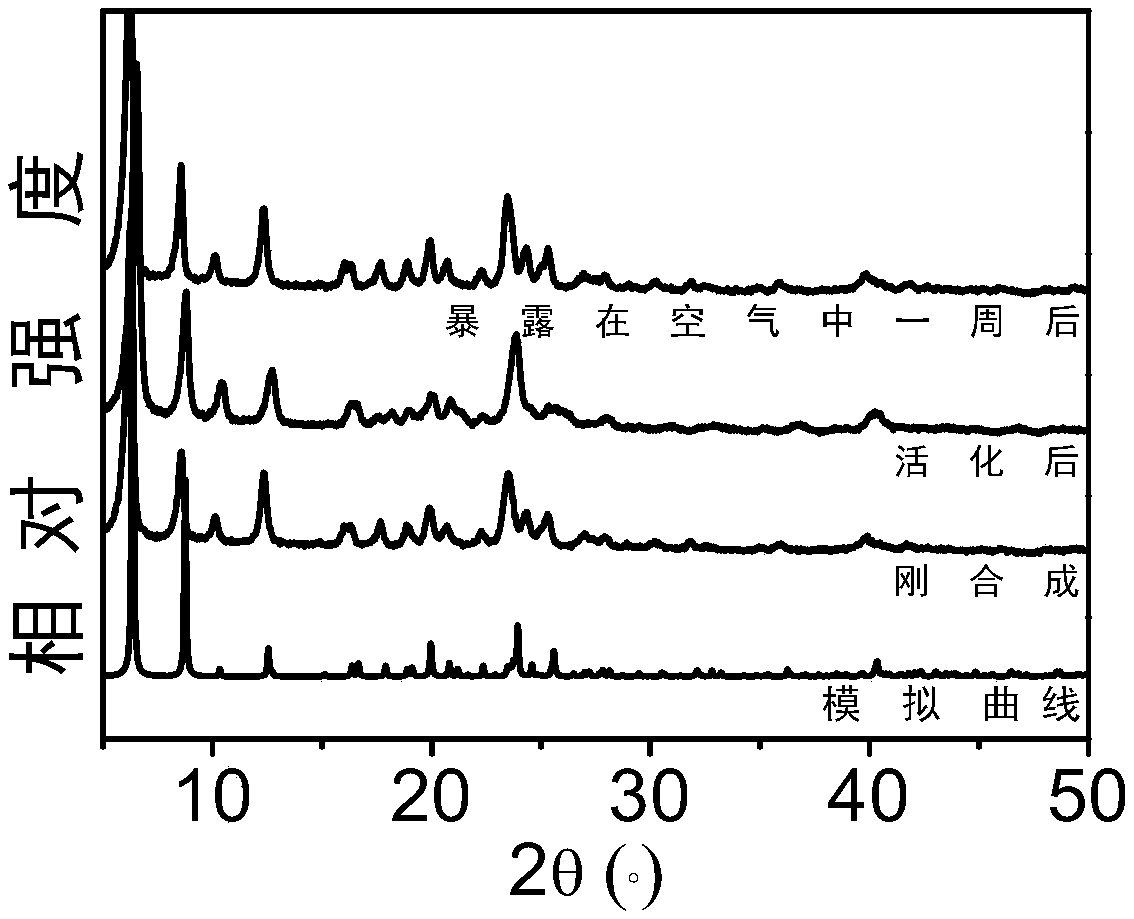

[0049] A water / ethanol (volume ratio 1:1) solution containing 1 mmol pyrazine-2,3-dicarboxylic acid, 2 mmol sodium hydroxide and 0.5 mmol 4,4'-bipyridyl was added dropwise to 1 mmol copper perchlorate hexahydrate Compound in water / ethanol (volume ratio 1:1) solution, stirred at room temperature for 24 hours. The solid obtained from the reaction was washed with water and methanol several times in sequence to obtain the purified metal-organic framework material. The XRD characterization data of the material structure is shown in the attached image 3 . The purified adsorbent was vacuum degassed at 120 °C for 12 hours to obtain the desolvated adsorbent, followed by gas adsorption.

[0050] To test the adsorption-separation performance of the above-synthesized MOFs, a single-component adsorption isotherm of ethylene acetylene was carried out using the above-mentioned adsorbents. Take 100mg of adsorbent and set the adsorption temperature to 0°C. After testing, at 25°C and 1 bar,...

Embodiment 3

[0054] Add the aqueous solution containing 1mmol pyrazine-2,3-dicarboxylic acid, 2mmol sodium hydroxide and 0.5mmol triethylenediamine dropwise to the aqueous solution containing 1mmol copper perchlorate hexahydrate to react at room temperature, and the resulting solid Washing with water and methanol several times in sequence to obtain the purified metal-organic framework material. The purified adsorbent was vacuum degassed at 120 °C for 12 hours to obtain the desolvated adsorbent, followed by gas adsorption.

[0055] To test the adsorption-separation performance of the above-synthesized MOFs, a single-component adsorption isotherm of ethylene acetylene was carried out using the above-mentioned adsorbents. Take 100mg of adsorbent and set the adsorption temperature to 0°C. After testing, at 25°C and 1 bar, the adsorption capacity of acetylene reaches 0.372mmol / g, and the adsorption capacity of ethylene is only 0.159mmol / g.

[0056] In order to test the stability of the sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com