Method for preparing perovskite thin film by dynamic spin coating

A perovskite and spin-coating technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of a large number of pinholes in the microscopic appearance of perovskite films, affecting battery conversion efficiency and stability, and perovskite Problems such as uneven distribution of ore precursor liquid, to achieve high photoelectric conversion efficiency, reduced recombination probability, and excellent photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Ultrasonic cleaning of the glass with detergent, deionized water, absolute ethanol, and acetone, followed by ultraviolet and ozone cleaning;

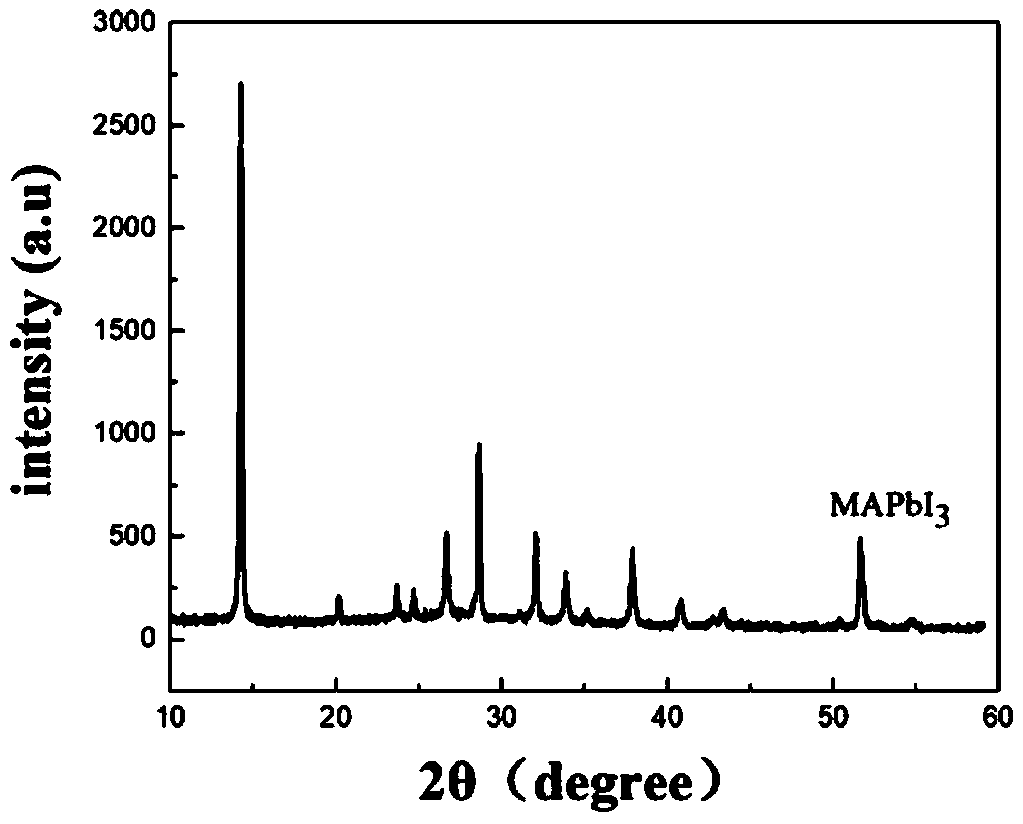

[0028] 2) Combine MAI and PbI 2 According to the ratio of 1:1, it was dissolved in the mixed solution of DMF and DMSO with a volume ratio of 4:1, stirred and reacted at 70°C for 12 hours, and 1M MAPbI was prepared. 3 Perovskite precursor;

[0029] 3) Put the washed glass slide on the spin coater, add 200μm dense layer solution dropwise, spin coat at 1000rpm for 10s, then spin coat at 3500rpm for 35s, then place the slide on a heating plate at 125°C for 5min and anneal Take it off, wait for cooling to room temperature for the second spin coating;

[0030] 4) Place the glass substrate after the second spin coating on a heating plate at 125°C, raise the temperature by 25°C every 2 minutes, and keep it at 500°C for 1.5-2h;

[0031] 5) Set the parameters of the spin coater, high speed 5000rmp, 15s; low speed 3500rmp, 45s;

[00...

Embodiment 2

[0038] 1) Ultrasonic cleaning of the glass with detergent, deionized water, absolute ethanol, and acetone, followed by ultraviolet and ozone cleaning;

[0039] 2) CsI, FAI and PbI 2 According to the ratio of 1:9:10, it was dissolved in the mixed solution of DMF and DMSO with a volume ratio of 4:1, and stirred and reacted for 12 hours at 70 degrees to prepare 1M Cs 0.1 FA 0.9 PB 3 Perovskite precursor;

[0040] 3) Put the washed glass slide on the spin coater, add 200μm dense layer solution dropwise, spin coat at 1000rpm for 10s, then spin coat at 3500rpm for 35s, then place the slide on a heating plate at 125°C for 5min. Take it off, wait for cooling to room temperature for the second spin coating;

[0041] 4) Place the glass substrate after the second spin coating on a heating plate at 125°C, raise the temperature by 25°C every 2 minutes, and keep it at 500°C for 1.5-2h;

[0042] 5) Set the parameters of the spin coater, high speed 6000rmp, 15s; low speed 4000rmp, 45s; ...

Embodiment 3

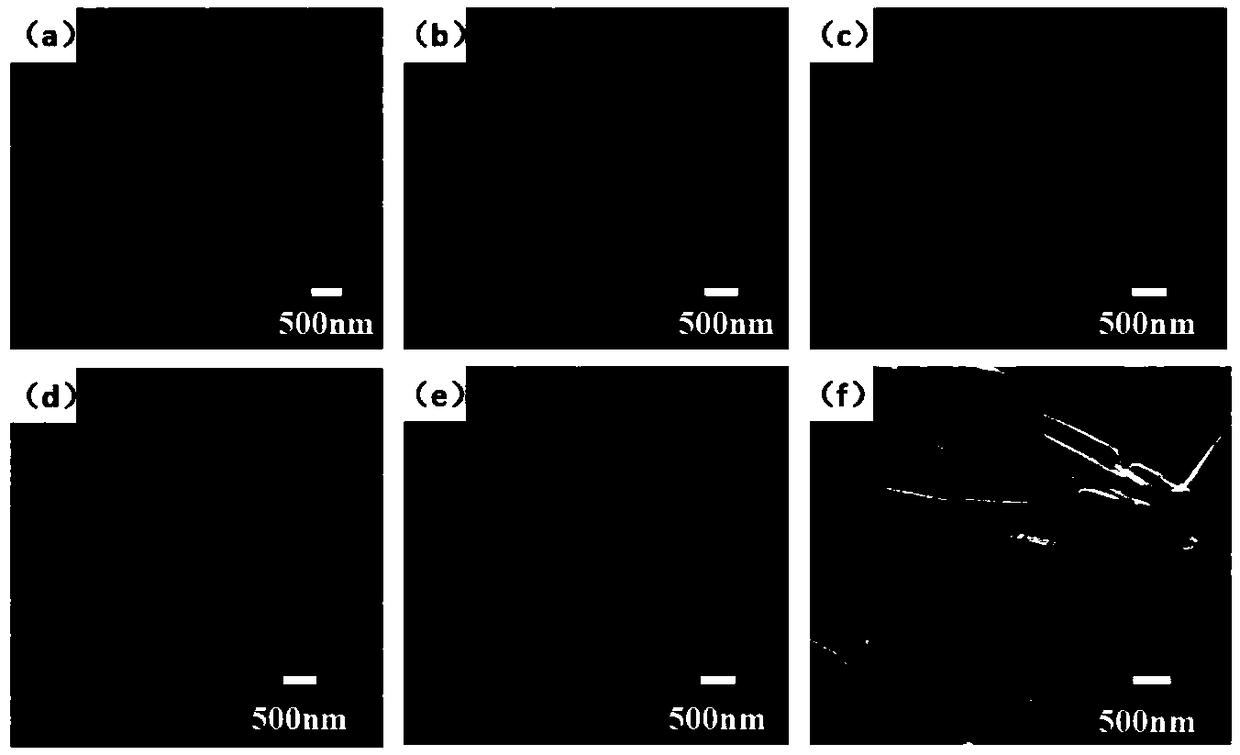

[0047] This embodiment is basically the same as Embodiment 1, the only difference is that the rotational speed of the high-speed spin coating is 4000 rpm. The film prepared in this embodiment, its SEM picture is as follows figure 2 As shown in (c), the microscopic morphology of the perovskite film is observed to have uniform grains, no pinholes, and complete coverage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com