Construction method of fabricated water stop platform in kitchen and bathroom

A construction method and technology of a water stop, which are applied in building components, building insulation materials, buildings, etc., can solve the problems of difficult control of reserved pipelines, poor anti-seepage effect, time-consuming and labor-intensive, etc., and achieve light weight, convenient transportation and installation. Reinforce simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

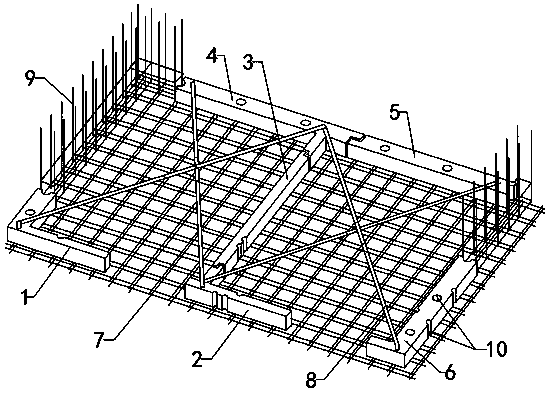

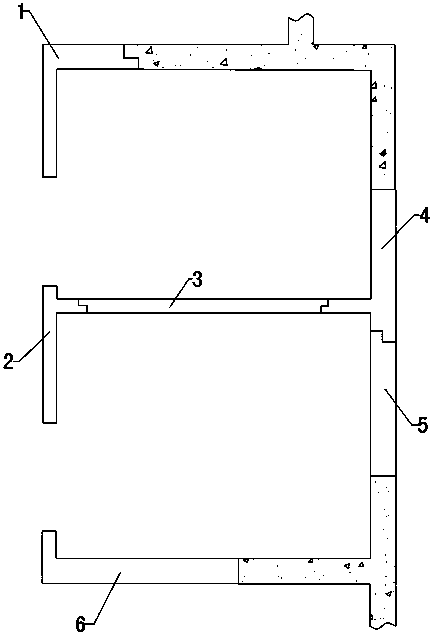

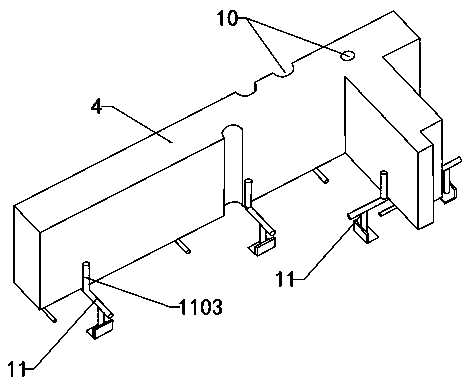

[0029] Schematic design: Segment the water stop platform according to the architectural drawings, refer to the attached figure 2 : Take each wall as a waterstop section, design the location of the waterstop sections, and number them respectively as the first segmental concrete waterstop prefabricated part 1, the second segmental concrete waterstop prefabricated part 2, and the second segmental concrete waterstop prefabricated part 2. Three-section concrete waterstop prefabrication 3, fourth section concrete waterstop prefabrication 4, fifth section concrete waterstop prefabrication 5, sixth section concrete waterstop prefabrication 6, each waterstop The connection end of the platform section with the similar waterstop section is reserved, and CAD and REVIT software are used to design and draw; the design is safe, economical and reasonable, and the dimensions are clearly marked;

[0030] Processing and production: According to the shape and size of each waterstop section, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com