Method of manufacturing semiconductor device

A manufacturing method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

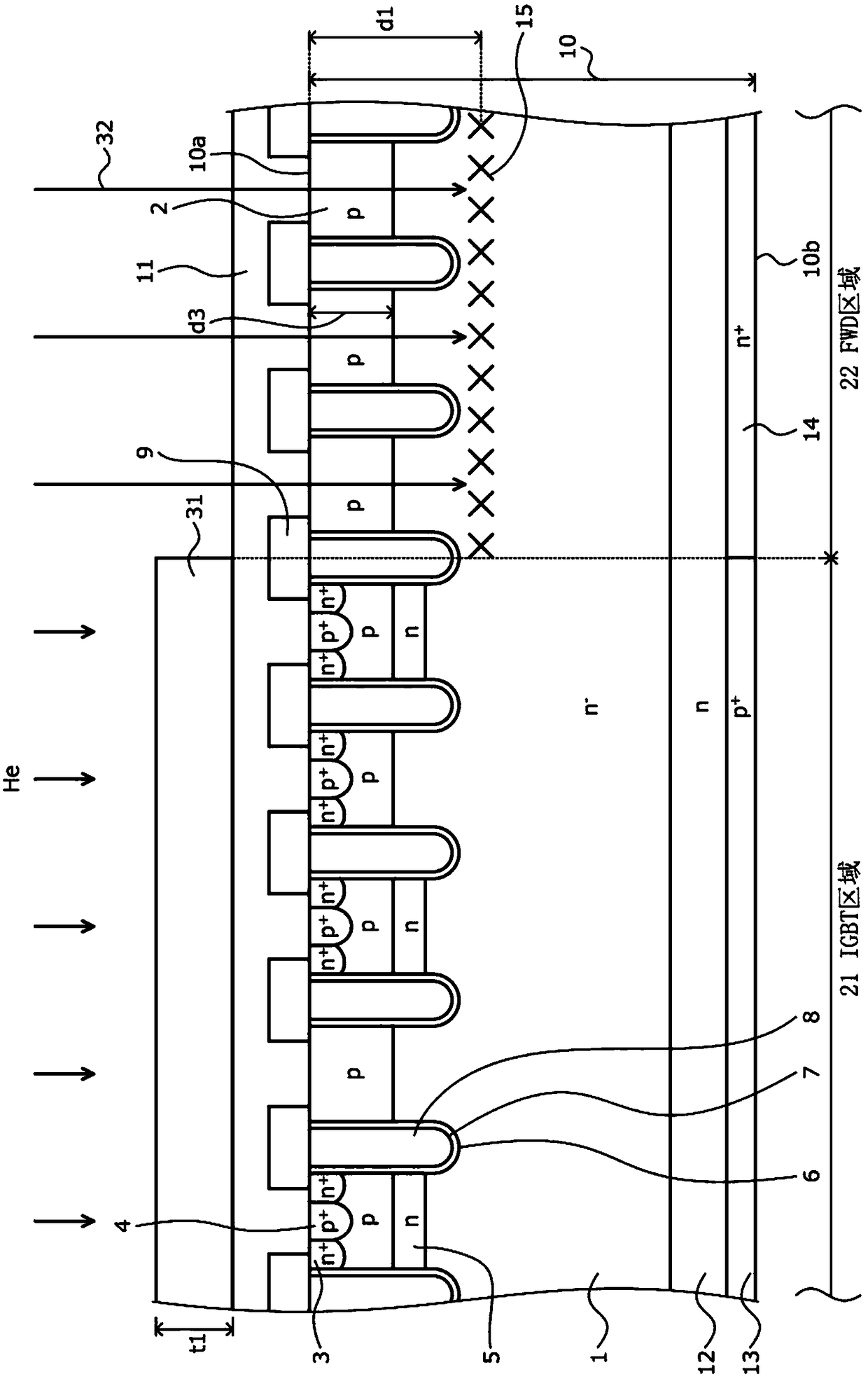

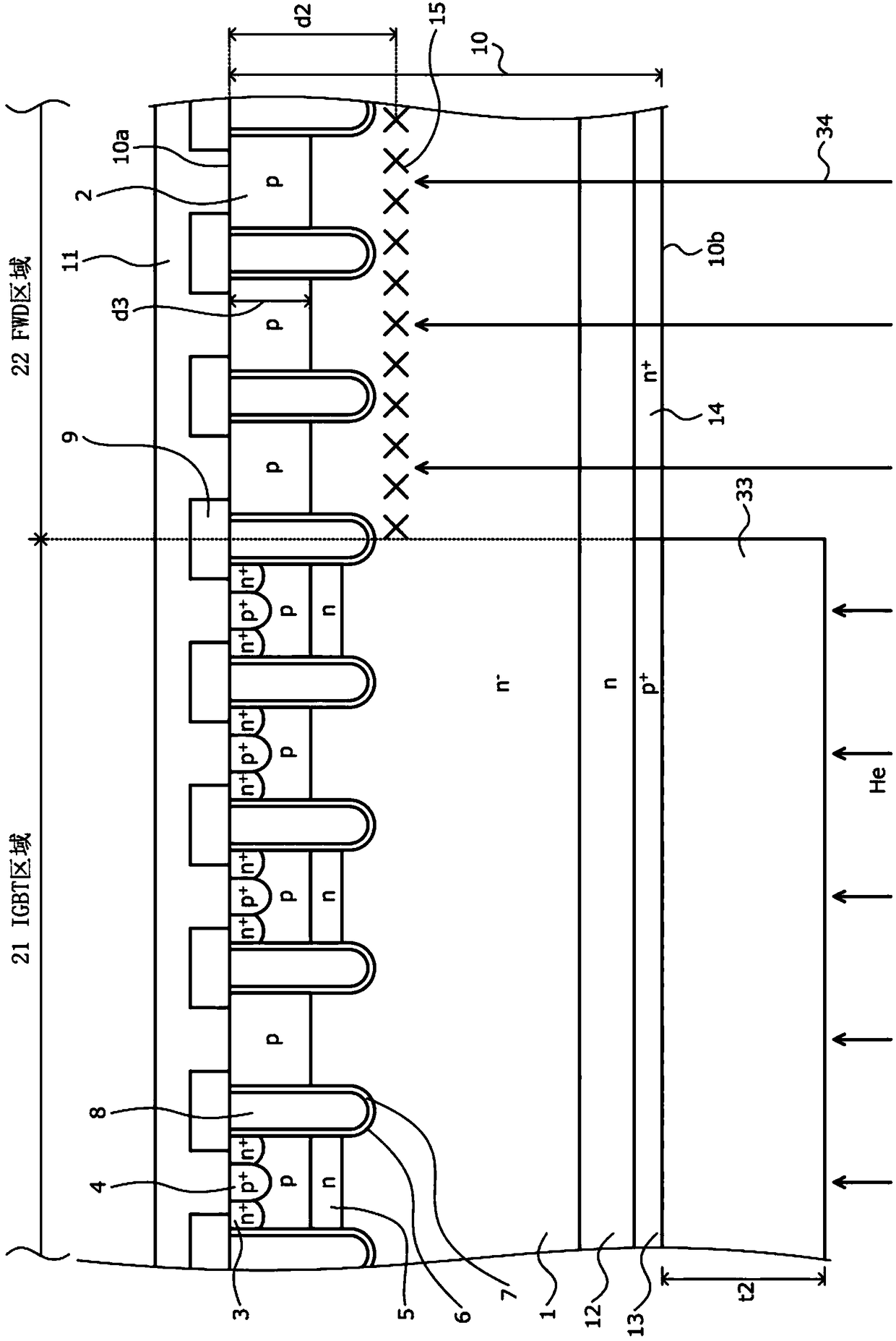

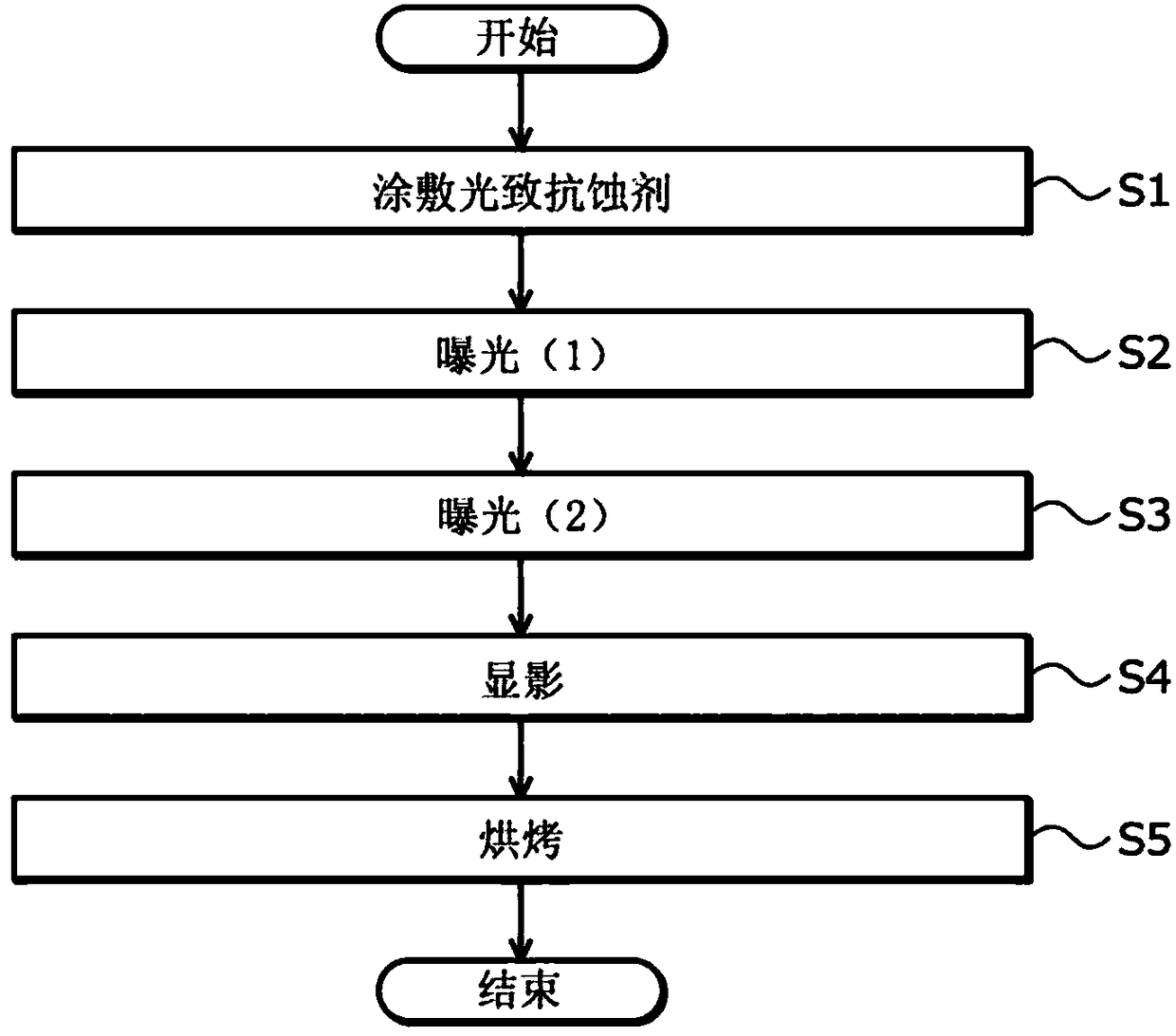

[0074] The manufacturing method of the semiconductor device according to the embodiment will be described taking, as an example, an RC-IGBT of a breakdown voltage of 1200 V class in which helium defects are introduced by irradiation of helium (He) in the FWD region. The so-called withstand voltage is a limit voltage at which a device does not malfunction and / or be destroyed. figure 1 It is a cross-sectional view showing the state during the manufacturing process of the semiconductor device according to the embodiment. figure 2 It is a cross-sectional view showing another example of the state in the manufacturing process of the semiconductor device according to the embodiment. exist figure 1 , figure 2 In , the states where helium irradiation is performed from the front side 10 a side and the back side 10 b side of the semiconductor wafer 10 are schematically shown, respectively.

[0075] The RC-IGBT is formed, for example, by integrating an IGBT having a trench gate str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com