Composite material with interface enhanced and application thereof

A composite material and interface enhancement technology, which is applied in the coating process of metal materials, the device for coating liquid on the surface, ion implantation plating, etc., can solve the problems of low mechanical strength, loss, fatigue effect, etc., and increase the total contact Improvement of area, wear resistance, and elimination of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

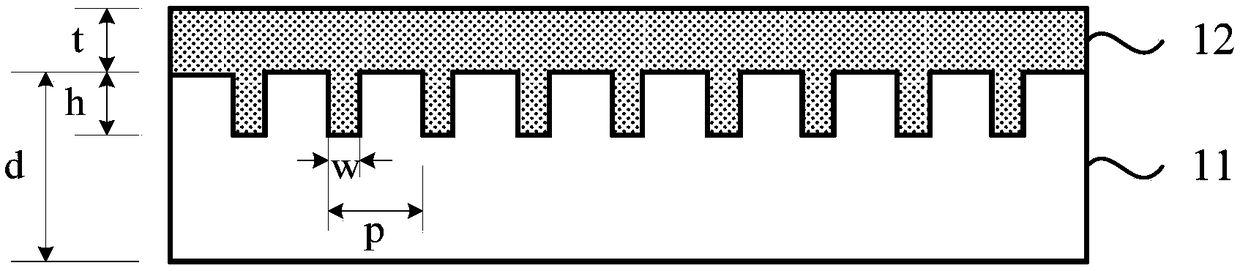

[0053] Because of its transparency, glass materials are widely used in vehicle windows, or the surface of electronic equipment. But the disadvantage of glass material is that it is fragile and heavy. The lightweight of modern automobiles can save the energy consumption of vehicles and reduce environmental pollution, so it has been paid more and more attention. Engineering plastics, such as PMMA and PC, have the characteristics of light weight, transparency and non-fragmentation, and are ideal glass replacement materials. However, the relatively poor mechanical properties of polymer materials, such as Young's modulus, hardness, and low surface scratch resistance, make them unable to completely replace glass. For example, the windshield of a car, due to the back and forth scraping of the wiper, the surface is quickly scratched, affecting the line of sight. To solve this problem, a possible solution is to coat the polymer surface with an inorganic film. For example, the use of...

Embodiment 2

[0057] The difference from Example 1 is that the depth h of the hole is 1 μm.

Embodiment 3

[0059] The difference from Example 1 is that the depth h of the hole is 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com