Preparation method of polymer matrix controllable graded pore material

A polymer and hierarchical pore technology, which is applied in the field of inorganic, organic and polymer materials, can solve the problems that the pore size of the material is difficult to be effectively controlled, it is difficult to prepare porous microspheres with pores, and it depends on the external reaction conditions of the emulsifier. Achieve good industrialization development prospect, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: the three-dimensional ordered macroporous copolymer (comparative example) that does not add porogen synthesis;

[0047] (1) Preparation of 200nm silica colloidal crystal template;

[0048] Utilize according to patent CN101691426A -Fink-Hohn synthesis method, add 127g of absolute ethanol, 30g of ammonia water with a mass fraction of 25%, and 60.5g of deionized water into a 500mL three-necked bottle equipped with mechanical stirring at room temperature (25°C), stir evenly, and then Quickly add 16.8 g of ethyl orthosilicate to the three-necked flask, and react at room temperature for 8 hours. Transfer the obtained suspension to a beaker, wait for the solvent to volatilize completely naturally, and obtain a colloidal silica template with an average particle size of 200nm, and finally sinter the template in a muffle furnace at 500°C for 3 hours, and slowly lower it to room temperature to obtain The silica colloidal crystal template with an average particle s...

Embodiment 2

[0053] Embodiment 2: Oligomer is used as porogen to synthesize hierarchical hole poly(styrene-divinylbenzene) copolymer HPP(St-DVB)-PPG;

[0054](1) The preparation of 200nm silica colloidal crystal template is the same as step (1) in the embodiment one;

[0055] (2) The oligomer polypropylene glycol (PPG) is used as a porogen to synthesize hierarchically porous poly(styrene-divinylbenzene) copolymer HPP(St-DVB)-PPG;

[0056] The sintered colloidal silica template obtained in the 10g dried step (1) is placed in the reactor, and 0.84g monomer and 3.8g crosslinking agent mixed solution (mass ratio DVB: St=9:2), 3mL polypropylene glycol (PPG) and 0.023g initiator azobisisobutyronitrile (AIBN) mixed solution was dispersed at a high speed of 6000r / min for 10min, then poured into the container, submerged in the sintered carbon dioxide Silica colloidal crystal template, after half an hour, put it in an oven at 65°C for 4h, then raise the temperature to 80°C for 24h, and the polymer / ...

Embodiment 3

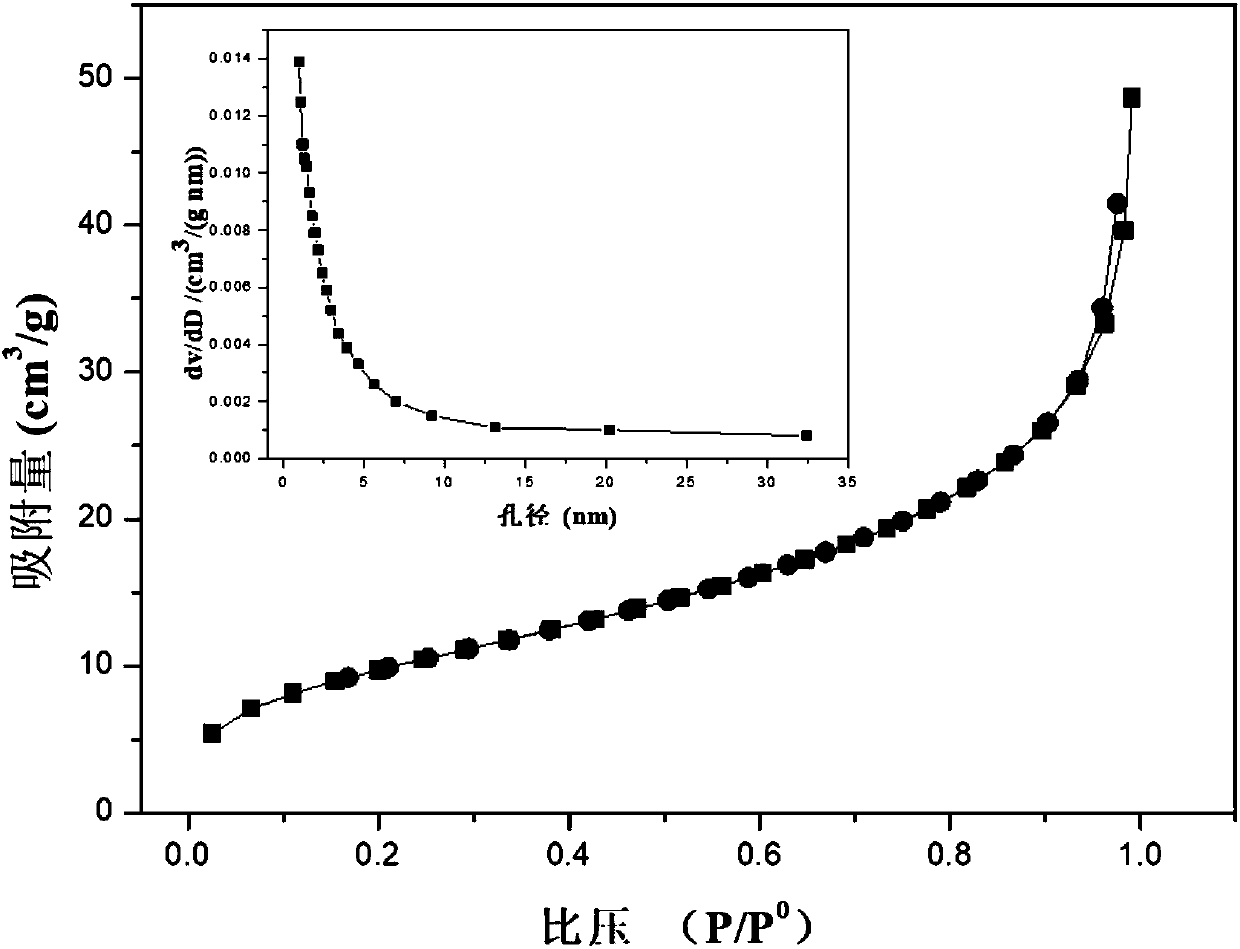

[0059] Example 3: Using toluene and polypropylene glycol as porogens to synthesize hierarchically porous poly(styrene-divinylbenzene) copolymer HP P(St-DVB)-Toluene-PPG;

[0060] (1) The preparation of 200nm silica colloidal crystal template is the same as step (1) in the embodiment one;

[0061] (2) The polypropylene glycol in Example 2 was replaced by a mixture of toluene and polypropylene glycol, the feed ratio of toluene and polypropylene glycol was the volume ratio Toluene:PPG=1:6, and the remaining steps were referred to Example 2. Material HP PDVB-Toluene-PPG its nitrogen adsorption and desorption curve and pore size distribution see Image 6 , the type IV isotherm shows that the material has a mesoporous structure. According to the BJH pore size distribution diagram, the material has mesopores of about 2.5nm and mesopores of about 20nm, forming a hierarchical pore combining multi-scale mesopores and ordered macropores. structure. The specific surface area of BET is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com