Method for preparing fluorine-containing nitrile rubber with low-temperature emulsion polymerization

An emulsion polymerization, fluorine-containing nitrile technology is applied in the field of preparation of nitrile rubber, which can solve the problems of not specifying the preparation method of ternary copolymer rubber, and achieve the effects of good elasticity, good wear resistance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

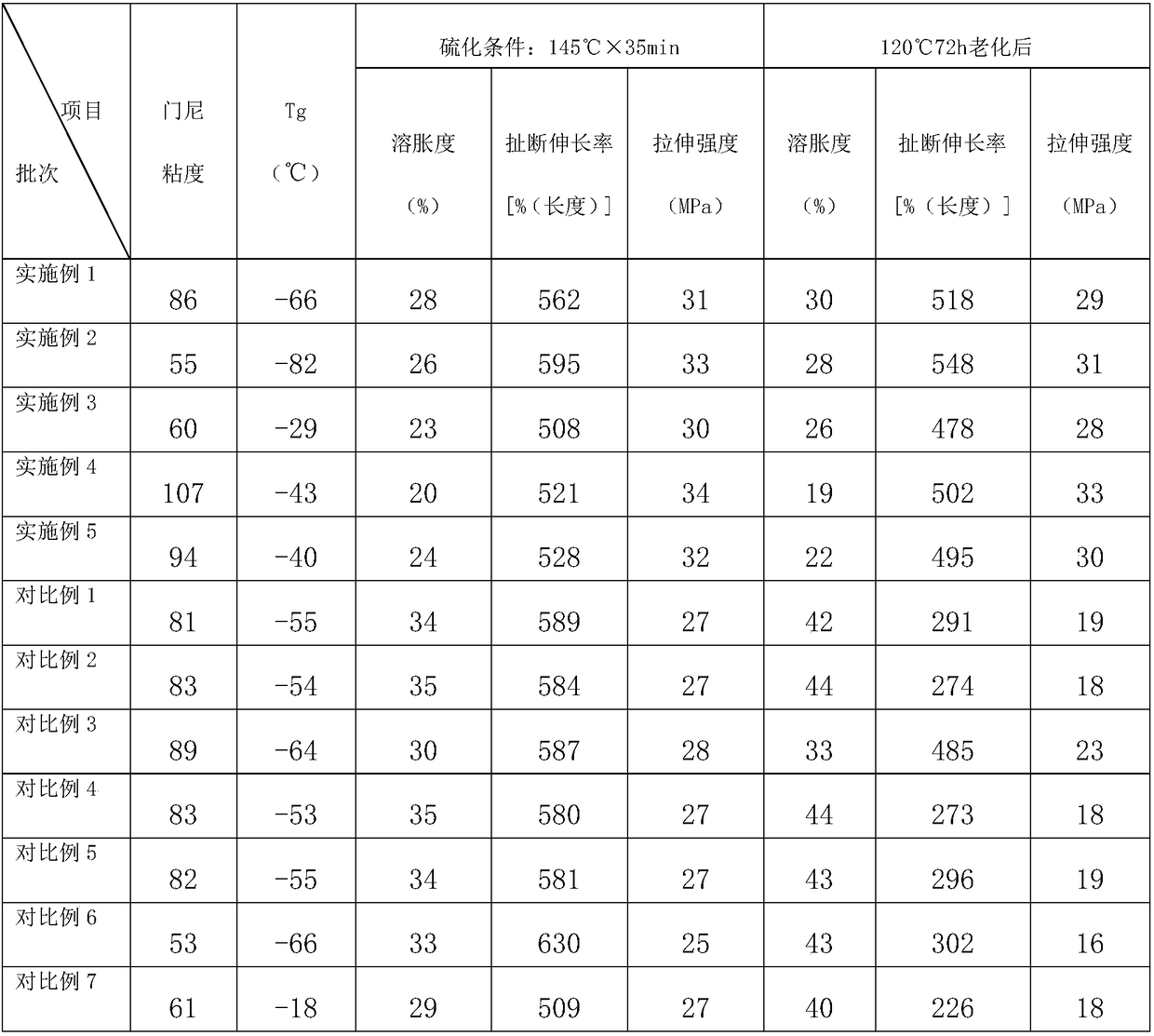

[0042] In the reaction kettle, first add 25 parts of acrylonitrile, 2 parts of hexafluorobutyl acrylate, 3 parts of hexafluorobutyl methacrylate mixed monomer and 0.075 parts of tm-200s, 75 parts of butadiene, 150 parts of water, 3 Part sodium dodecylbenzenesulfonate, 2 parts emulsifier A, 0.50 part tertiary dodecyl mercaptan, 0.2 part sodium carbonate, 0.01 part ferrous sulfate, 0.1 part sodium formaldehyde sulfoxylate, 0.05 part EDTA disodium salt , pre-emulsified for 40 minutes, then added 0.2 parts of cumene hydroperoxide, and controlled the temperature to carry out copolymerization at a polymerization temperature of 5°C. When reaching 80%, 0.4 part of diethylhydroxylamine was added to terminate the polymerization. The properties of the obtained fluorine-containing nitrile rubber are shown in Table 1.

Embodiment 2

[0054] In the reaction kettle, first add 20 parts of acrylonitrile and 10 parts of dodecylfluoroheptyl methacrylate mixed monomer and 0.48 parts of tm-200s, 80 parts of butadiene, 250 parts of water, 2 parts of dodecylbenzenesulfonate sodium nitrate, 5 parts of synthetic fatty acid potassium, 2.5 parts of emulsifier B, 1 part of emulsifier C, 1 part of n-dodecyl mercaptan, 0.5 part of sodium carbonate, 0.09 part of EDTA iron sodium salt, 0.36 part of glucose, 0.2 part of amino tris Sodium acetate, pre-emulsified for 50 minutes, then added 0.4 parts of dicumyl hydroperoxide, and controlled the temperature to carry out copolymerization at a polymerization temperature of 8°C, and then added 0.2 parts of n-dodecyl mercaptan when the conversion rate reached 40%. When the conversion rate reached 75%, 0.3 parts of hydroquinone and 0.3 parts of diethylhydroxylamine were added to terminate the polymerization. The properties of the obtained fluorine-containing nitrile rubber are shown i...

Embodiment 3

[0058] In the reaction kettle, first add 45 parts of acrylonitrile and 1 part of hexafluorobutyl acrylate mixed monomer and 0.0013 parts of tm-200s, 55 parts of butadiene, 300 parts of water, 1 part of synthetic fatty acid potassium, 4 parts of disproportionated abietic acid Potassium, 0.5 part of emulsifier C, 0.34 part of tertiary dodecyl mercaptan, 1.1 part of dithiodiisopropyl xanthate, 0.1 part of sodium acetate, 0.001 part of cuprous sulfate, 0.006 part of sodium formaldehyde sulfoxylate, 0.01 part of EDTA disodium salt, pre-emulsified for 30 minutes, then added 0.007 part of hydrogen peroxide p-menthane, and controlled the temperature to carry out copolymerization at a polymerization temperature of 14°C. When the conversion rate reached 84%, added 0.04 part of diethylhydroxylamine and 0.07 parts of hydroquinone terminated the polymerization. The properties of the obtained fluorine-containing nitrile rubber are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com