A high-fidelity high-frequency circuit board

A high-frequency circuit board and circuit board technology, applied in the directions of printed circuits, printed circuits, printed circuit components, etc., can solve the problems of restricting the wiring of printed circuit boards, reducing the shielding effect at openings, and limiting the shape of portable devices. Excellent high and low temperature resistance, excellent electromagnetic shielding performance, good hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

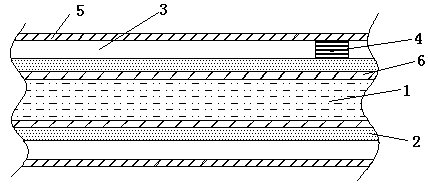

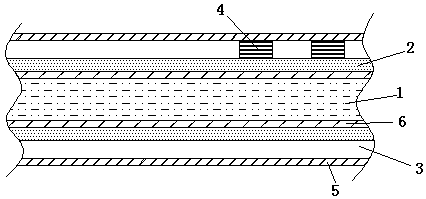

[0025] A high-fidelity high-frequency circuit board, the circuit board includes a circuit layer 1, and an insulating layer 2 arranged on the front and back of the circuit layer 1, and a layer of metal layer 3 is also arranged on the insulating layer 2, and the metal layer 3 on the top Layer 3 is partially laminated with a high-frequency sub-board 4 .

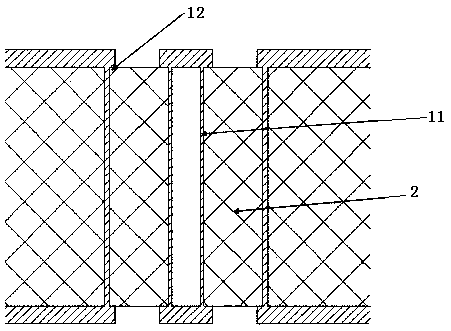

[0026] The circuit board also includes four first metal holes 11 arranged on the circuit board, and second metal holes 12 are respectively sleeved on the outer circumference of the first metal holes 11, and the second metal holes 12 and the first metal holes The holes 11 are concentric; the second metal hole 12 is grounded, and an insulating layer 2 is provided between the second metal hole 12 and the first metal hole 11 .

[0027] The surface of the metal layer 3 at the top or bottom is provided with a metal platinum coating 5, and the thickness of the metal platinum coating 5 is 4.5um.

[0028] The metal layer 3 is a metal fo...

Embodiment 2

[0034] A high-fidelity high-frequency circuit board, the circuit board includes a circuit layer 1, and an insulating layer 2 arranged on the front and back of the circuit layer 1, and a layer of metal layer 3 is also arranged on the insulating layer 2, and the metal layer 3 on the top Layer 3 is partially laminated with two high-frequency sub-boards 4 .

[0035] The circuit board also includes four first metal holes 11 arranged on the circuit board, and second metal holes 12 are respectively sleeved on the outer circumference of the first metal holes 11, and the second metal holes 12 and the first metal holes The holes 11 are concentric; the second metal hole 12 is grounded, and an insulating layer 2 is provided between the second metal hole 12 and the first metal hole 11 .

[0036] The surface of the metal layer 3 at the top or bottom is provided with a metal platinum coating 5, and the thickness of the metal platinum coating 5 is 4um.

[0037] The metal layer 3 is a metal f...

Embodiment 3

[0043] A high-fidelity high-frequency circuit board, the circuit board includes a circuit layer 1, and an insulating layer 2 arranged on the front and back of the circuit layer 1, and a layer of metal layer 3 is also arranged on the insulating layer 2, and the metal layer 3 on the top Layer 3 is partially laminated with a high-frequency sub-board 4 .

[0044] The circuit board also includes four first metal holes 11 arranged on the circuit board, and second metal holes 12 are respectively sleeved on the outer circumference of the first metal holes 11, and the second metal holes 12 and the first metal holes The holes 11 are concentric; the second metal hole 12 is grounded, and an insulating layer 2 is provided between the second metal hole 12 and the first metal hole 11 .

[0045] The surface of the metal layer 3 at the top or bottom is provided with a metal platinum coating 5, and the thickness of the metal platinum coating 5 is 3um.

[0046] The metal layer 3 is a metal foil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com