High-precision gas detector

A gas detector and composite nanofiber technology, applied in the field of detectors, can solve the problems of low sensitivity, poor mechanical stability, restricting the use of SnO2-based gas sensors, etc., and achieve the effect of process optimization and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

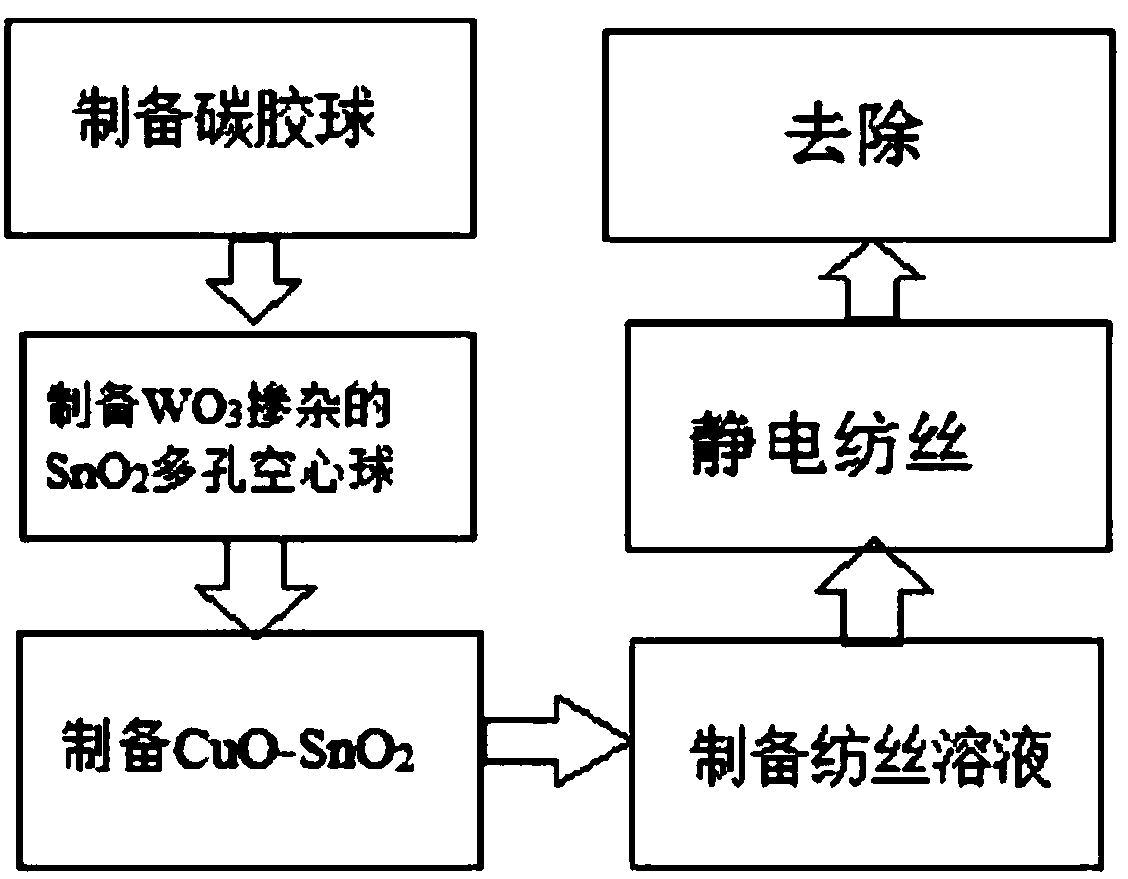

Method used

Image

Examples

Embodiment 1

[0040] In the present embodiment, the preparation steps of the SnO2 composite nanofibers:

[0041] Step 1. Preparation of carbon rubber balls

[0042]Add 16g of glucose to 120ml of deionized water to dissolve, stir evenly, then heat the solution at a constant temperature of 160°C for 10h, after the reaction is completed, cool it down to room temperature naturally, then use alcohol and deionized water to separate and wash by centrifugation, and repeat the washing three times. Obtain dark brown product carbon rubber balls, which are dried at 70°C for 10 hours for later use;

[0043] Step 2, preparation of WO3 doped SnO2 porous hollow spheres

[0044] Add 0.8-1.0g of tungstic acid and tin chloride to the mixture of 75ml of ethanol and 8ml of water and stir evenly, then add 0.2g of urea and stir evenly; then add the carbon rubber balls prepared in step 1 into the solution, ultrasonically disperse and statically place, centrifuge, wash, dry at 80°C for 12h, and finally dry the dr...

Embodiment 2

[0055] In the present embodiment, the preparation steps of the SnO2 composite nanofibers:

[0056] Step 1. Preparation of carbon rubber balls

[0057] Add 20g of glucose to 120ml of deionized water to dissolve, stir evenly, then heat the solution at a constant temperature of 160°C for 10h, after the reaction is over, let it cool down to room temperature naturally, then centrifuge and wash with alcohol and deionized water in turn, and repeat the washing three times, Obtain dark brown product carbon rubber balls, which are dried at 70°C for 10 hours for later use;

[0058] Step 2, preparation of WO3 doped SnO2 porous hollow spheres

[0059] Add 1.0g of tungstic acid and tin chloride to the mixture of 75ml of ethanol and 8ml of water and stir evenly, then add 0.2g of urea and stir evenly; then add the carbon glue balls prepared in step 1 into the solution, ultrasonically disperse and let stand, Centrifuge, wash, and dry at 80°C for 12 hours, and finally dry the dried product at...

Embodiment 3

[0070] In the present embodiment, the preparation steps of the SnO2 composite nanofibers:

[0071] Step 1. Preparation of carbon rubber balls

[0072] Add 19g of glucose to 120ml of deionized water to dissolve, stir evenly, then heat the solution at a constant temperature of 160°C for 10h, after the reaction is completed, cool it down to room temperature naturally, then use alcohol and deionized water to separate and wash by centrifugation, and repeat the washing three times. Obtain dark brown product carbon rubber balls, which are dried at 70°C for 10 hours for later use;

[0073] Step 2, preparation of WO3 doped SnO2 porous hollow spheres

[0074] Add 0.9g of tungstic acid and tin chloride to the mixture of 75ml of ethanol and 8ml of water and stir evenly, then add 0.2g of urea, and stir evenly; then add the carbon glue balls prepared in step 1 into the solution, ultrasonically disperse and let stand, Centrifuge, wash, and dry at 80°C for 12 hours, and finally dry the drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com