Penicillium, method for preparing D-mannitol through microbial metabolism of penicillium and applications

A technology of Penicillium and mannitol, which is applied in the field of preparation of D-mannitol, can solve problems such as the development restriction of industrial production of D-mannitol, and achieve the effects of no environmental pollution, mild reaction conditions and simple equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Cell activation: inoculate Penicillium T2-8-10 into the PDA slant medium sterilized at 121°C for 30 minutes, culture it in a constant temperature incubator at 28°C for 5 days, and then place it in a refrigerator at 4°C for use.

[0028] Strain preparation: Inoculate activated bacteria into PDB medium sterilized at 121°C for 30 minutes, and ferment for 3 days at 28°C and 150 rpm.

[0029] Fermentation process: Add the prepared strains according to the volume fraction of 10% into the fermentation medium sterilized at 121° C. for 30 minutes (the components of the fermentation medium in terms of volume mass percentage: 2.8% glucose, 0.2% dipotassium hydrogen phosphate, 0.2% magnesium sulfate heptahydrate, 20% potato juice 1L, 2 mg per liter of thiamine), at 25° C., 150 rpm for 9 days of fermentation.

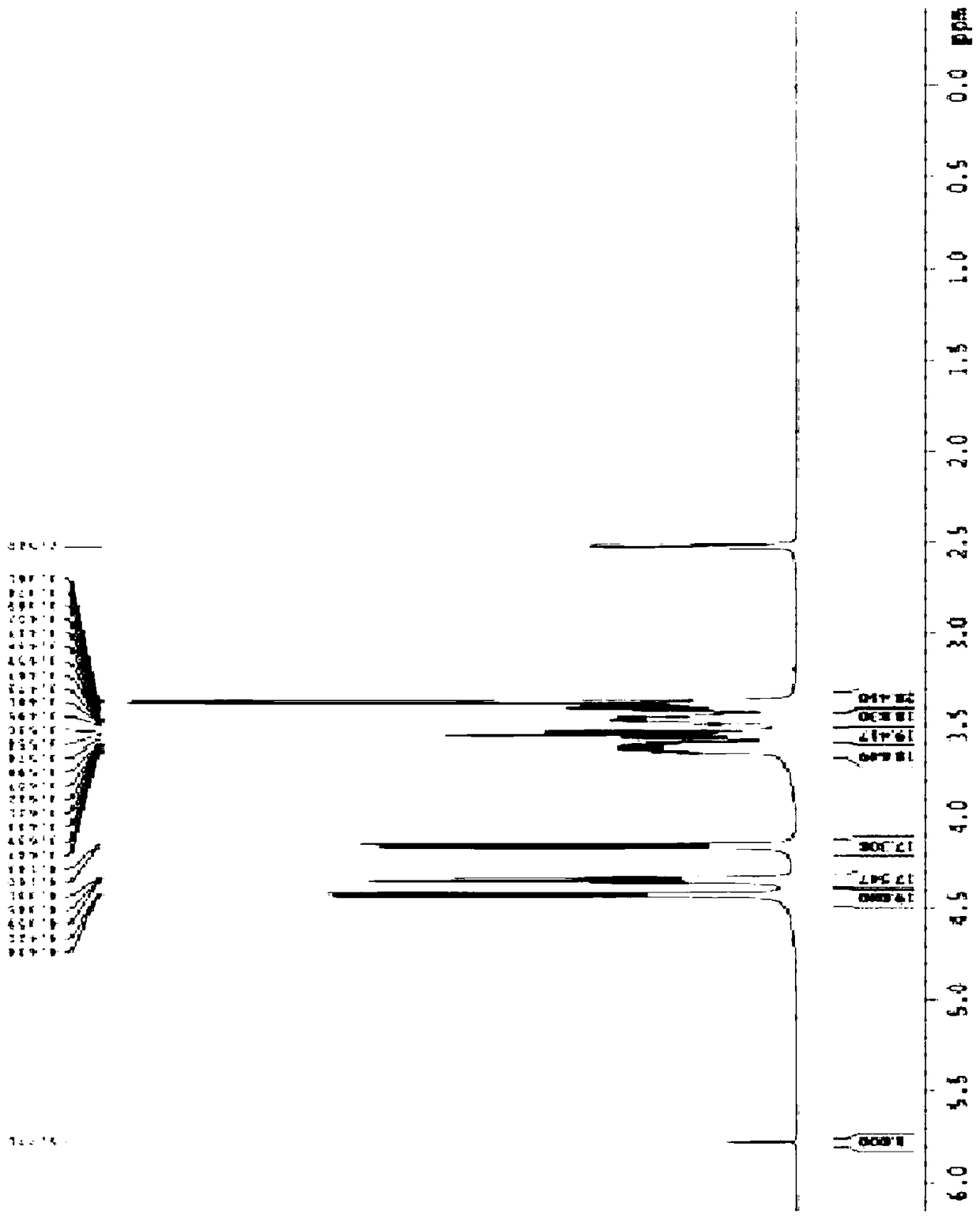

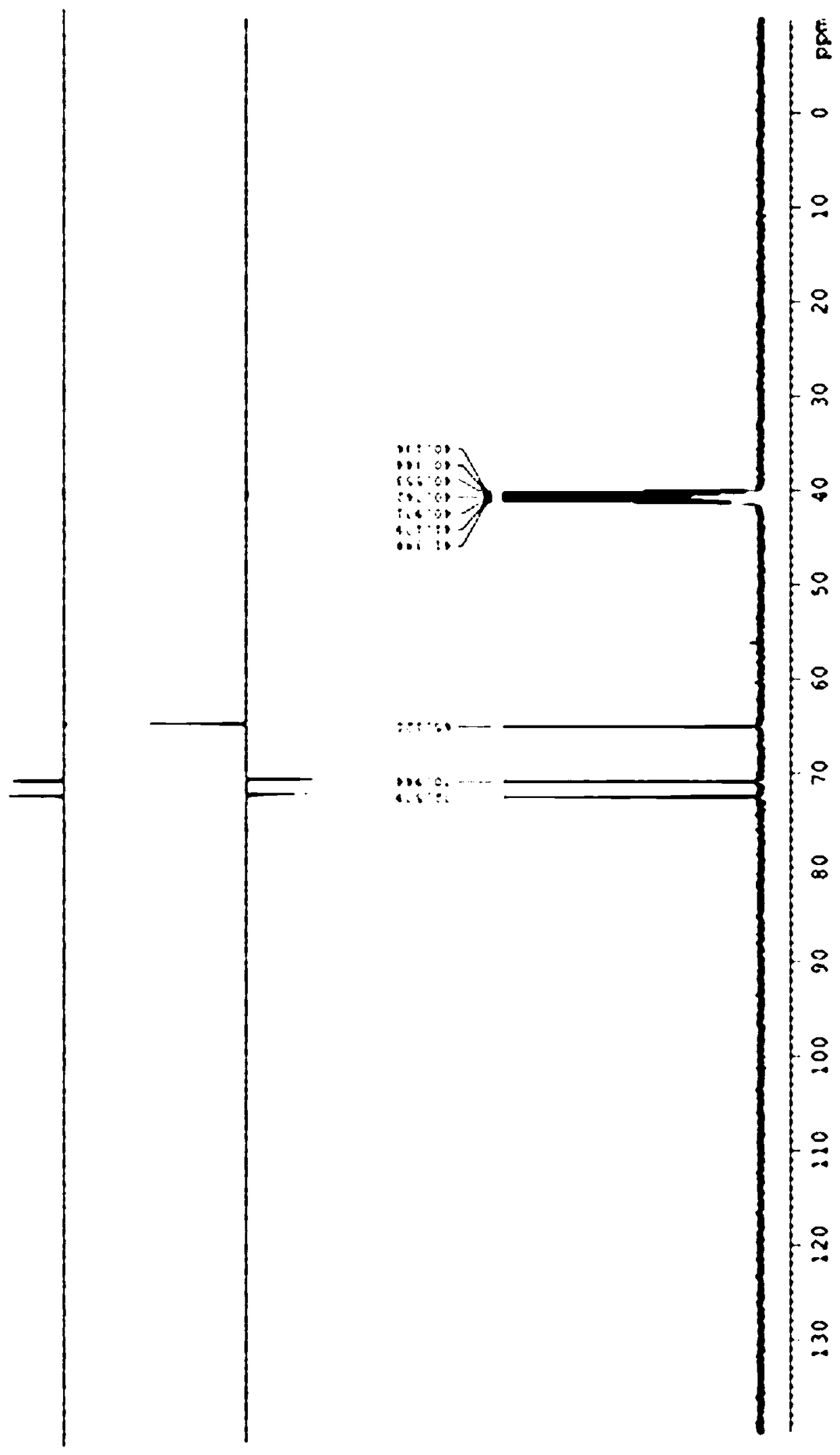

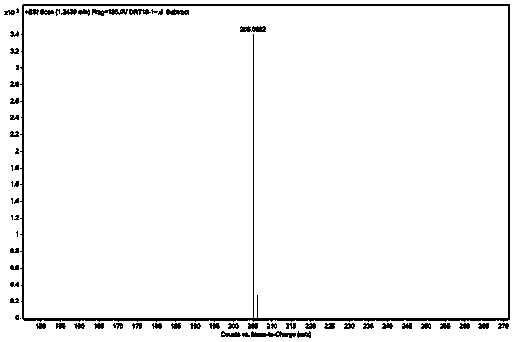

[0030] After the fermentation, the fermentation liquid and the cells were ultrasonically broken for 30 minutes, and analyzed by high-performance liquid chromatography, the co...

Embodiment 2

[0033] Cell activation: inoculate Penicillium T2-8-10 into the PDA slant medium sterilized at 121°C for 30 minutes, culture it in a constant temperature incubator at 28°C for 5 days, and then place it in a refrigerator at 4°C for use.

[0034] Strain preparation: Inoculate activated bacteria into PDB medium sterilized at 121°C for 30 minutes, and ferment for 3 days at 28°C and 150 rpm.

[0035] Fermentation process: Add the prepared strains according to the volume fraction of 5% into the fermentation medium sterilized at 121° C. for 30 minutes (the components of the fermentation medium in terms of volume mass percentage: 2% glucose, 0.1% dipotassium hydrogen phosphate, 0.1% magnesium sulfate heptahydrate, 20% potato juice 1L, 2 mg per liter of thiamine), 28° C., 150 rpm for 9 days of fermentation.

[0036] After the fermentation, the fermentation liquid and the cells were ultrasonically broken for 30 minutes, and analyzed by high-performance liquid chromatography, the concentr...

Embodiment 3

[0039] Cell activation: Inoculate Penicillium T2-8-10 into the PDA slant medium sterilized at 121°C for 30 minutes, culture it in a constant temperature incubator at 28°C for 5 days, and then place it in a refrigerator at 4°C. , Fermentation 3d under 150rpm.

[0040] Fermentation process: Add the prepared strains according to the volume fraction of 10% into the fermentation medium sterilized at 121° C. for 30 minutes (the components of the fermentation medium in terms of volume mass percentage: 0.4% glucose, 0.1% dipotassium hydrogen phosphate, 0.1% magnesium sulfate heptahydrate, 20% potato juice 1L, 2 mg per liter of thiamine), at 28° C., 150 rpm for 9 days of fermentation.

[0041] After the fermentation, the fermentation liquid and the cells were ultrasonically broken for 15 minutes, and analyzed by high performance liquid chromatography, the concentration of D-mannitol in the fermentation liquid was 1.26 g / L.

[0042] The fermented liquid was extracted twice with equal vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com