Weather-resistant composite material for lighting, lighting plate and preparation method thereof

A composite material and weather resistance technology, applied in the field of materials, can solve the problems of long-term use, low bearing capacity of lighting panels, poor lighting effect, etc., to meet the requirements, improve brittleness, and reduce the effect of curing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

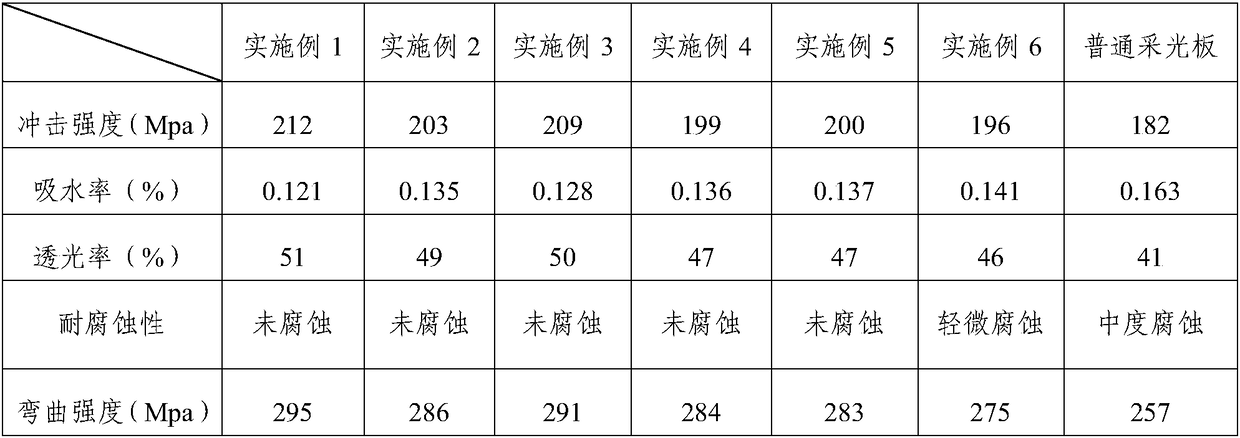

Examples

Embodiment 1

[0021] A weather-resistant composite material for lighting, prepared from the following raw materials in parts by weight: 13 parts of xylene formaldehyde resin, 11 parts of phenolic resin, 12 parts of vinyl ester resin, and 12 parts of isophthalic acid polyester resin 6 parts, 6 parts of methacrylic acid, 5 parts of ethylenediaminetetraacetic acid, 4 parts of ultraviolet absorber, 1.5 parts of curing agent, 1 part of accelerator, 1.5 parts of flame retardant, 1.8 parts of antioxidant, 25 parts of glass fiber.

[0022] Wherein, the ultraviolet absorber is composed of diethyl terephthamethylene bismalonate, phenyl salicylate and triazole compounds in a component ratio of 1:1.5:0.8.

[0023] Wherein, the curing agent is composed of a composition of tert-butyl perbenzoate, triammonium citrate and ammonium chloride / ammonium sulfamate in a component ratio of 1:0.6:0.2.

[0024] Wherein, the accelerator is 1,4-diazabicyclo[2.2.2]octane.

[0025] Wherein, the flame retardant is compo...

Embodiment 2

[0033] A weather-resistant composite material for daylighting, prepared in parts by weight from the following raw materials: 12 parts of xylene formaldehyde resin, 10 parts of phenolic resin, 13 parts of vinyl ester resin, and 13 parts of isophthalic acid polyester resin 7 parts of methacrylic acid, 3 parts of ethylenediaminetetraacetic acid, 5 parts of ultraviolet absorber, 1 part of curing agent, 0.8 parts of accelerator, 1 part of flame retardant, 1.2 parts of antioxidant, 24 parts of glass fiber.

[0034] Wherein, the ultraviolet absorber is composed of a composition of diethyl terexylylene bis malonate and phenyl salicylate in a component ratio of 1:1.2.

[0035] Wherein, the curing agent is composed of a composition of tert-butyl perbenzoate and triammonium citrate at a component ratio of 1:0.5.

[0036] Wherein, the accelerator is 1,4-diazabicyclo[2.2.2]octane.

[0037] Wherein, the flame retardant is tris(2,3-dichloropropyl) phosphate.

[0038] Wherein, the antioxida...

Embodiment 3

[0045] A weather-resistant composite material for lighting, prepared from the following raw materials in parts by weight: 14 parts of xylene formaldehyde resin, 12 parts of phenolic resin, 15 parts of vinyl ester resin, and 11 parts of isophthalic acid polyester resin 5 parts, 5 parts of methacrylic acid, 6 parts of ethylenediaminetetraacetic acid, 3 parts of ultraviolet absorber, 1.5 parts of curing agent, 1 part of accelerator, 1.2 parts of flame retardant, 1.5 parts of antioxidant, 26 parts of glass fiber.

[0046] Wherein, the ultraviolet absorber is composed of a composition of diethyl terexylylene bismalonate and a triazole compound in a component ratio of 1:1.

[0047] Wherein, the curing agent is composed of a composition of tert-butyl perbenzoate and ammonium chloride / ammonium sulfamate at a component ratio of 1:0.35.

[0048] Wherein, the accelerator is 1,4-diazabicyclo[2.2.2]octane.

[0049] Wherein, the flame retardant is 2-carboxyethylphenylphosphorous acid.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com