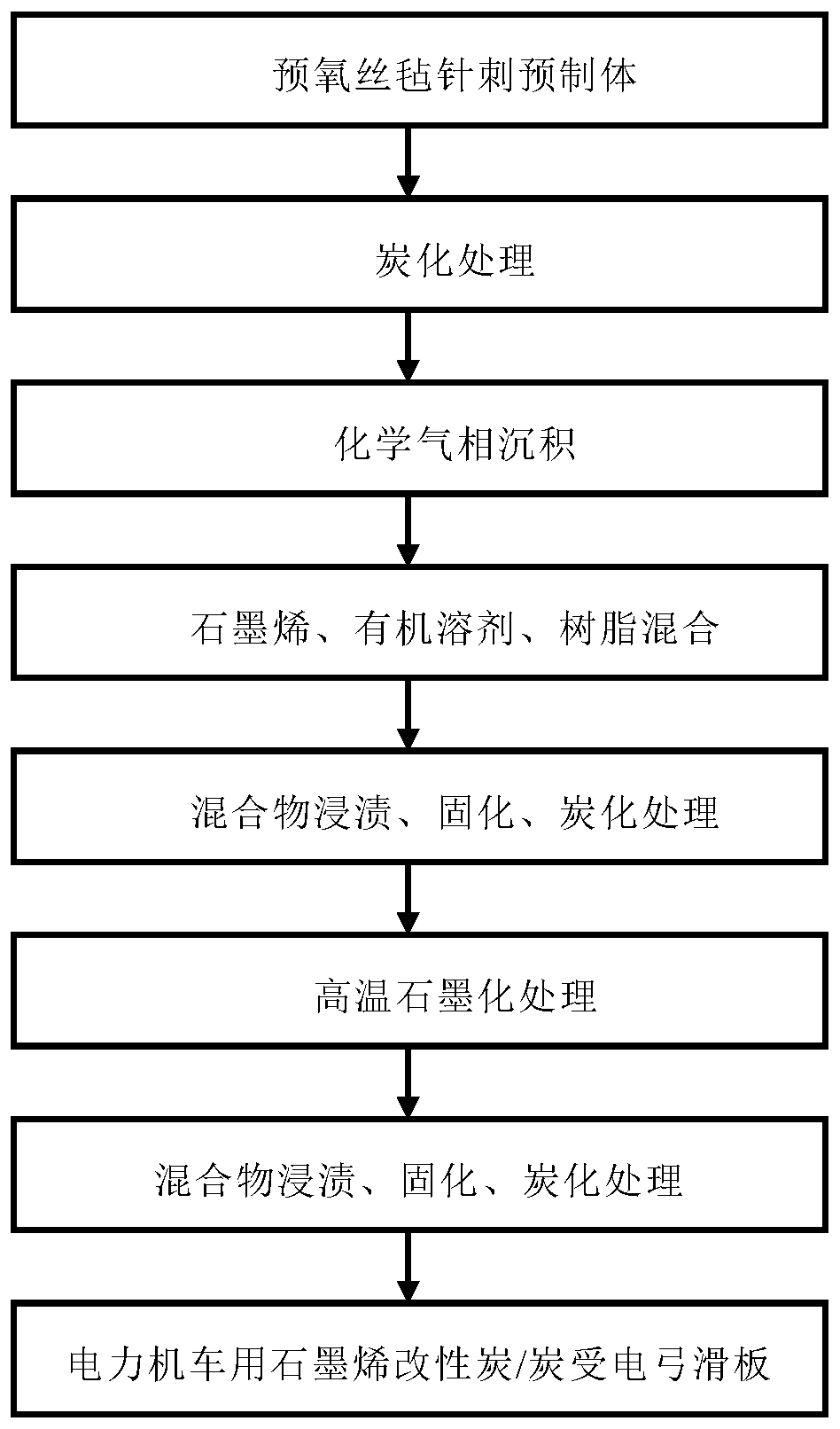

A preparation method of graphene modified carbon/carbon pantograph slide plate for electric locomotive

A graphene modification, pantograph sliding plate technology, applied in electric vehicles, current collectors, vehicle parts, etc., can solve the problems of the impact strength needs to be further improved, the mechanical strength of short fibers is not high, and the self-lubricating ability is not strong. , to achieve the effect of good impact toughness, high mechanical strength and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Use pre-oxygenated silk felt needled body as the prefabricated body material, and the density of the prefabricated body is controlled at 0.12g / cm 3 , the needle density of the pre-oxygenated silk felt needle-punched body is 20 needles / cm 2 .

[0028] Step 2: Carbonize the prefabricated body used in Step 1. The carbonization temperature is 550°C, the heating rate is 2°C / h, and the holding time is 1h.

[0029] Step 3: Densify the preform treated in step 2 by chemical vapor deposition, using methane and propane mixed gas as the carbon source gas, the mixed volume ratio of methane and propane is 1:0.5, and the gas flow rate is 0.5m 3 / h, the heating rate is 5°C / h, the deposition temperature is 800°C, and the deposition time is 300h. When the density ≥ 1.15g / cm 3 Then transfer to the next dense process.

[0030] Step 4: Mix and dilute the graphene with an organic solvent and resin, pressurize and immerse the porous carbon / carbon composite body after chemical vapor...

Embodiment 2

[0037] Step 1: Use pre-oxygenated silk felt needled body as the prefabricated body material, and the density of the prefabricated body is controlled at 0.18g / cm 3 , the needle density of the pre-oxygenated silk felt needle-punched body is 40 needles / cm 2 .

[0038] Step 2: Carbonize the prefabricated body used in Step 1. The carbonization temperature is 650°C, the heating rate is 10°C / h, and the holding time is 2h.

[0039] Step 3: Densify the preform treated in step 2 by chemical vapor deposition, using methane and propane mixed gas as the carbon source gas, the mixed volume ratio of methane and propane is 1:3, and the gas flow rate is 2.5m 3 / h, the heating rate is 50°C / h, the deposition temperature is 900°C, and the deposition time is 150h. When the density ≥ 1.15g / cm 3 Then transfer to the next dense process.

[0040] Step 4: After mixing and diluting the graphene with an organic solvent and resin, pressurize and immerse the porous carbon / carbon composite body after ch...

Embodiment 3

[0047] Step 1: Use pre-oxygenated silk felt as the preform material, and the density of the preform is controlled at 0.30g / cm 3 , the needle density of the pre-oxygenated silk felt needle-punched body is 80 needles / cm 2 .

[0048] Step 2: Carbonize the prefabricated body used in Step 1. The carbonization temperature is 700°C, the heating rate is 20°C / h, and the holding time is 8h.

[0049] Step 3: Densify the preform processed in step 2 by chemical vapor deposition, using methane and propane mixed gas as the carbon source gas, the mixed volume ratio of methane and propane is 1:6, and the gas flow rate is 6.0m 3 / h, the heating rate is 100°C / h, the deposition temperature is 1050°C, and the deposition time is 300h. When the density ≥ 1.15g / cm 3 Then transfer to the next dense process.

[0050] Step 4: After mixing and diluting the graphene with an organic solvent and resin, pressurize and immerse in the porous carbon / carbon composite body after chemical vapor deposition trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com