Composite material for reducing phenol emission from flue gas and preparation method and application thereof

A composite material and emission technology, applied in the field of tobacco, can solve the problems that affect the adsorption efficiency and capacity of harmful components, cannot effectively remove harmful substances, and cannot fully contact smoke, so as to achieve improved adsorption efficiency and capacity, low cost, and phenol The effect of content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of the composite material that reduces the amount of phenol release in the flue gas of the present embodiment is carried out as follows:

[0026] In 50g of 4wt% polyethylene glycol-water solution, add 3g of coconut shell activated carbon, ultrasonic 10min, take out and drain, then join in the configured 60g of 5wt% polymer-water solution, the polymer is molecular weight of 10000 Vinylpyrrolidone-maleic acid copolymer, after ultrasonication for 5 minutes to make it uniform, take it out and dry it, which is the required polyvinylpyrrolidone-activated carbon composite material product.

[0027] 50 mg of the above composite material was added to the cigarette tip rod.

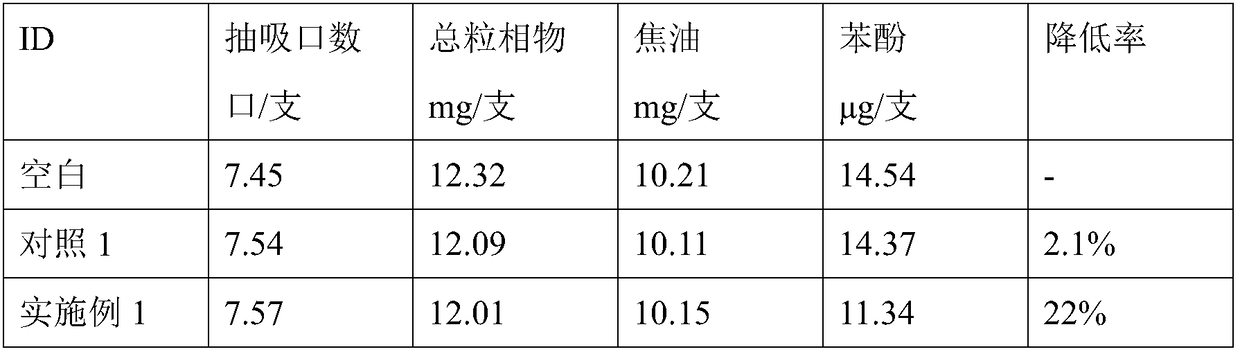

[0028] Smoke composition analysis was carried out on the prepared cigarettes, wherein the blank sample was a cigarette without any materials added, and the control sample was a cigarette directly added with the same weight and the same amount of activated carbon.

[0029] It can be se...

Embodiment 2

[0033] The preparation method of the composite material that reduces the amount of phenol release in the flue gas of the present embodiment is carried out as follows:

[0034] In 100g of 1wt% fatty acid sodium-triacetin solution, add 1g of sawdust activated carbon, ultrasonic 5min, take out and drain, then join in the configured 100g of 5wt% polyvinylpyrrolidone-triacetin solution, The molecular weight of polyvinylpyrrolidone is 1000. After ultrasonication for 5 minutes to make it uniform, take it out and dry it, which is the required polyvinylpyrrolidone-activated carbon composite material product.

[0035] 100 mg of the above composite material was added to the cigarette tip rod.

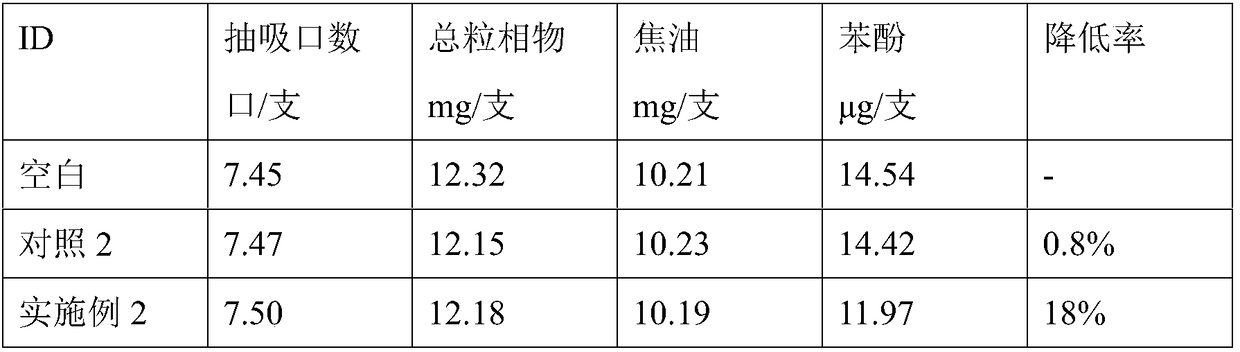

[0036] The smoke components of the prepared cigarettes were analyzed, and the results are shown in Table 2. The blank sample was a cigarette without any materials added, and the control sample 2 was a cigarette directly added with the same weight of activated carbon.

[0037] It can be seen from ...

Embodiment 3

[0041] The preparation method of the composite material that reduces the amount of phenol release in the flue gas of the present embodiment is carried out as follows:

[0042] Add 10g of walnut shell activated carbon in the 30wt% Span and sodium lauryl sulfate-ethanol solution of 100g, wherein, Span is 15g, sodium lauryl sulfate is 15g, ultrasonic 20min, take out and drain, then Add it to the prepared 100g of 10wt% polymer-ethanol solution, the polymer is polyvinylpyrrolidone with a molecular weight of 1,000,000, after ultrasonication for 30 minutes, take it out and dry it, which is the required polyvinylpyrrolidone-activated carbon composite material product .

[0043] 10 mg of the above composite material was added to the cigarette tip rod.

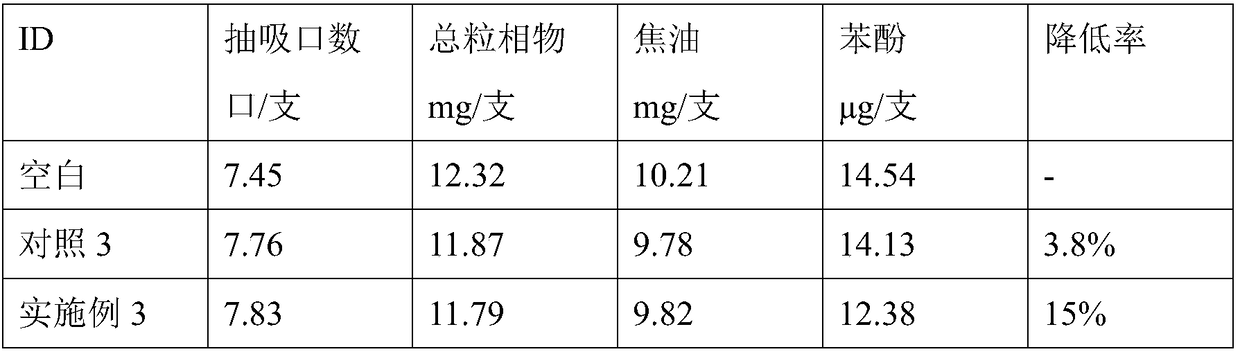

[0044] The smoke components of the prepared cigarettes were analyzed, and the results are shown in Table 3. The blank sample was a cigarette without any materials added, and the control 3 samples were cigarettes directly added with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com