Composite laminated magnetic material structure for electromagnetic shielding and preparation method thereof

A technology of magnetic material and composite lamination, applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, lamination, etc., can solve the problem of losing the function of magnetic isolation, burning batteries and electronic equipment, and changing the temperature stability of magnetic permeability. and other problems, to achieve the effect of improving charging efficiency and charging distance, preventing oversaturation abnormality, and reducing heating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] see Figure 4 and Figure 6 , the present invention provides a composite laminated magnetic material structure for electromagnetic shielding, the composite laminated magnetic material structure for electromagnetic shielding includes: a soft magnetic alloy steel strip material structure 1, and the soft magnetic alloy steel strip material structure 1 includes at least One layer of soft magnetic alloy steel strip material layer 11; ferrite magnetic material layer or magnetic powder adhesive material layer 2, the ferrite magnetic material layer or magnetic powder adhesive material layer 2 is pasted on the soft magnetic alloy steel strip Surface of Material Structure 1.

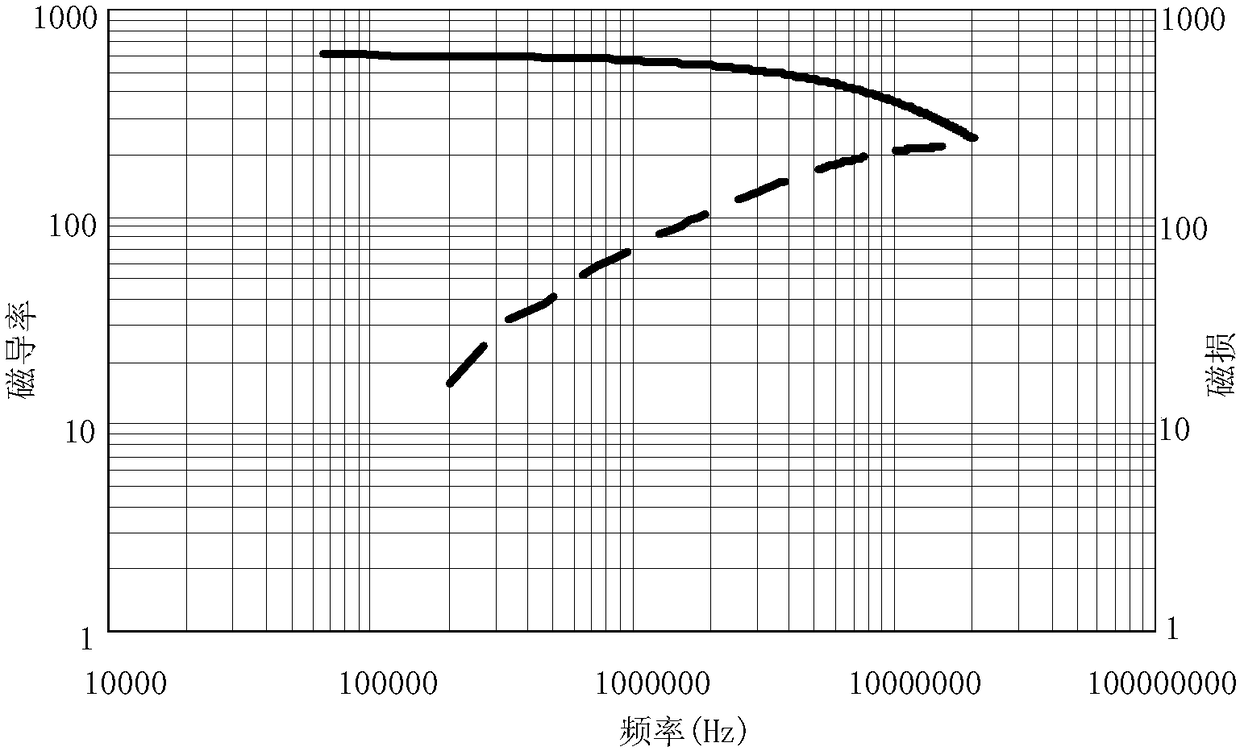

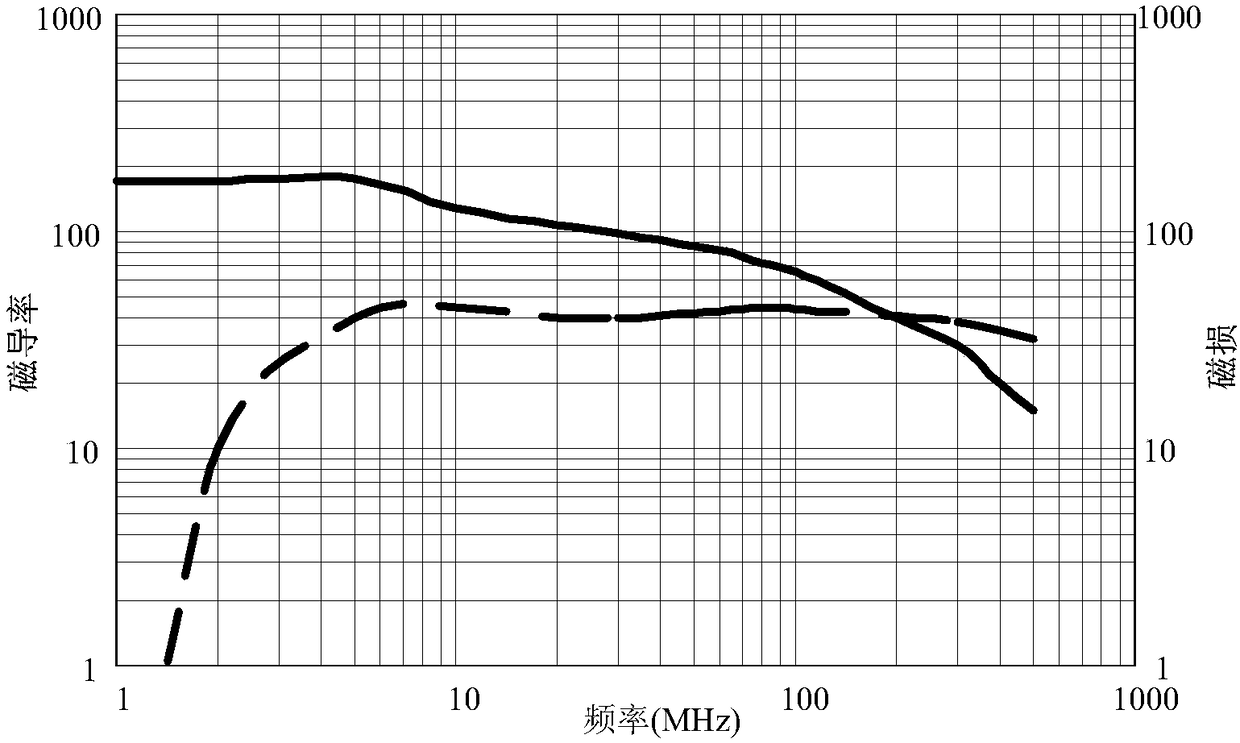

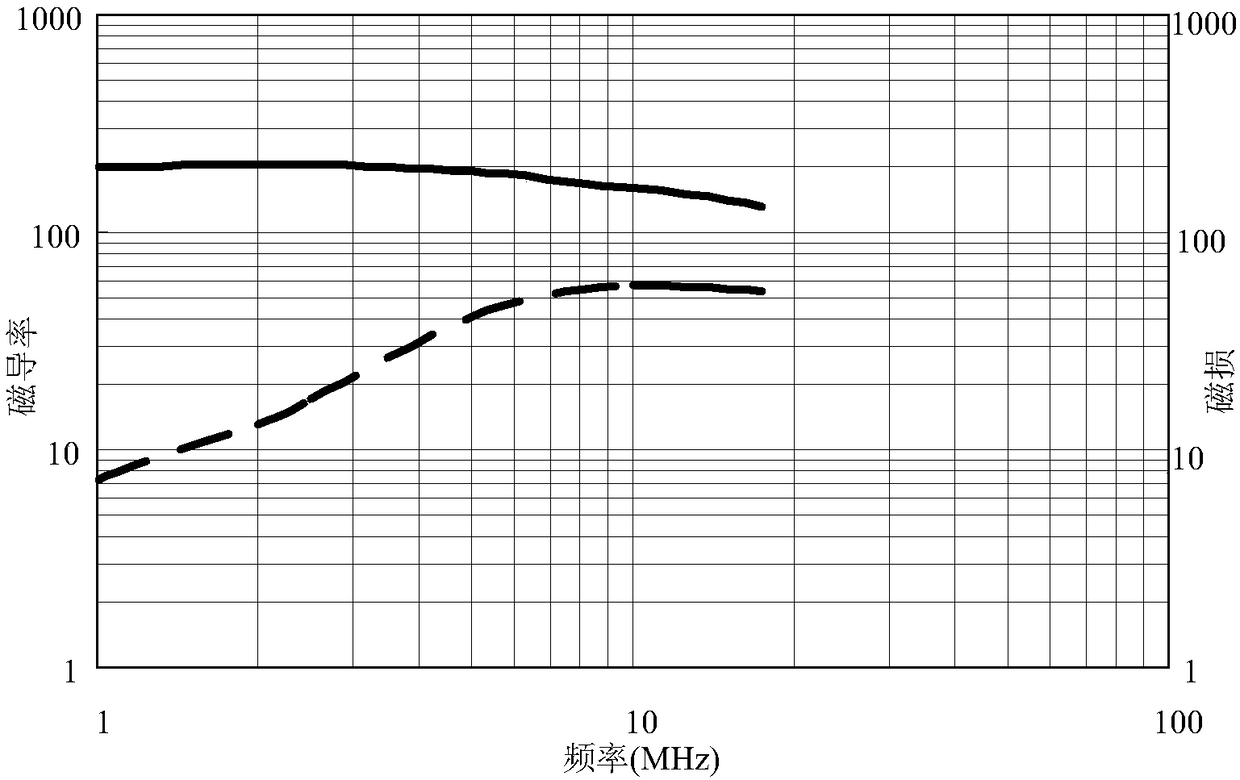

[0075] As an example, the material of the soft magnetic alloy steel strip material layer 11 can be electrical pure iron, oriented silicon steel sheet, super silicon steel sheet, permalloy or amorphous nanocrystalline alloy (1k101, 1k102, 1k103, 1k104, 1k105, 1k106 , 1k107, 1k201, 1k502, etc.), the saturat...

Embodiment 2

[0090] Please combine Figure 4 to Figure 7 refer to Figure 10 , the present invention also provides a method for preparing a composite laminated magnetic material structure for electromagnetic shielding, the preparation method is suitable for preparing the composite laminated magnetic material structure for electromagnetic shielding described in Example 1, the composite laminated magnetic material structure for electromagnetic shielding The preparation method of the laminated magnetic material structure comprises the following steps:

[0091] 1) preparing a soft magnetic alloy steel strip material structure, the soft magnetic alloy steel strip material structure comprising at least one soft magnetic alloy steel strip material layer;

[0092] 2) preparing a ferrite magnetic material layer or a magnetic powder adhesive material layer;

[0093] 3) Paste the soft magnetic alloy steel strip material structure on the surface of the ferrite magnetic material layer or the magnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation flux density | aaaaa | aaaaa |

| saturation flux density | aaaaa | aaaaa |

| saturation flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com