Graphite negative electrode material and preparation method thereof, negative electrode plate and lithium ion battery

A graphite anode and material layer technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high production cost, insufficient carbon layer density, battery flatulence, etc., to improve cycle life and high temperature performance, reduce graphite layers The effect of peeling off and reducing battery flatulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

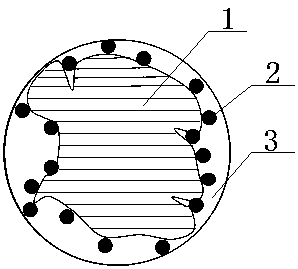

[0029] Such as figure 1 As shown, Embodiment 1 of the present invention provides a graphite negative electrode material for lithium ion batteries. The graphite negative electrode material includes a natural graphite sphere matrix 1, and the surface functional group position and the surface defect position on the natural graphite sphere matrix 1 are wrapped. Covered with an oxide layer 2, the surface of the natural graphite ball substrate 1 is covered with a pitch carbonization layer 3 except for the position where the oxide layer 2 is set and the surface of the oxide layer 2, and the pitch carbonization layer 3 is pitch of carbonization.

[0030] The graphite negative electrode material provided by the present invention is coated with an oxide layer at the position of the surface functional group and the position of the surface defect of the natural graphite ball matrix, which can avoid the side reaction of the defect and functional group on the surface of the natural graphite...

Embodiment 2

[0037] Such as figure 2 As shown, Embodiment 2 of the present invention provides a graphite negative electrode material for a lithium ion battery. The graphite negative electrode material includes a natural graphite sphere matrix 1, and is wrapped at the surface functional group position and the surface defect position on the natural graphite sphere matrix 1. Covered with an oxide layer 2, the surface of the natural graphite ball substrate 1 is covered with a phenolic resin carbonized layer 4 except for the position where the oxide layer 2 is set and the surface of the oxide layer 2, and the phenolic resin carbonized layer 4 It is a carbonized product of phenolic resin.

[0038] The surface of the natural graphite ball substrate of the graphite negative electrode material provided by the present invention is all coated with phenolic resin carbide layer 4 except that the oxide layer position and the surface of the oxide layer are covered, and the coating of phenolic resin carb...

Embodiment 3

[0045] The present invention also provides the preparation method of above-mentioned graphite negative electrode material, and this method comprises the steps:

[0046] 1) Coating the oxide layer on the surface functional group position and surface defect position on the natural graphite sphere substrate by atomic layer deposition method;

[0047] Specifically: S11, put the natural graphite sphere matrix powder into the porous container; put the porous container into the ALD reaction chamber, then repeatedly vacuumize and replace the nitrogen for at least three times; put the natural graphite sphere matrix powder in the atmosphere of nitrogen or argon Under fluidization (fluidization pressure is 1-1000torr) or by rotating the porous container to achieve powder dispersion effect;

[0048] S12, heating the temperature of the reaction chamber to 300-1000 Kelvin, keeping at the set temperature for 5-30 minutes, and the pressure in the reaction chamber is lower than 0.01 atmospheri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com