Amorphous carbon material and preparing method and application

A technology of amorphous carbon and carbon materials, applied in chemical instruments and methods, inorganic chemistry, electrode manufacturing, etc., can solve problems such as affecting the safety and service life of batteries, without considering heat transfer capacity, etc., to achieve high capacity and simple operation. , the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

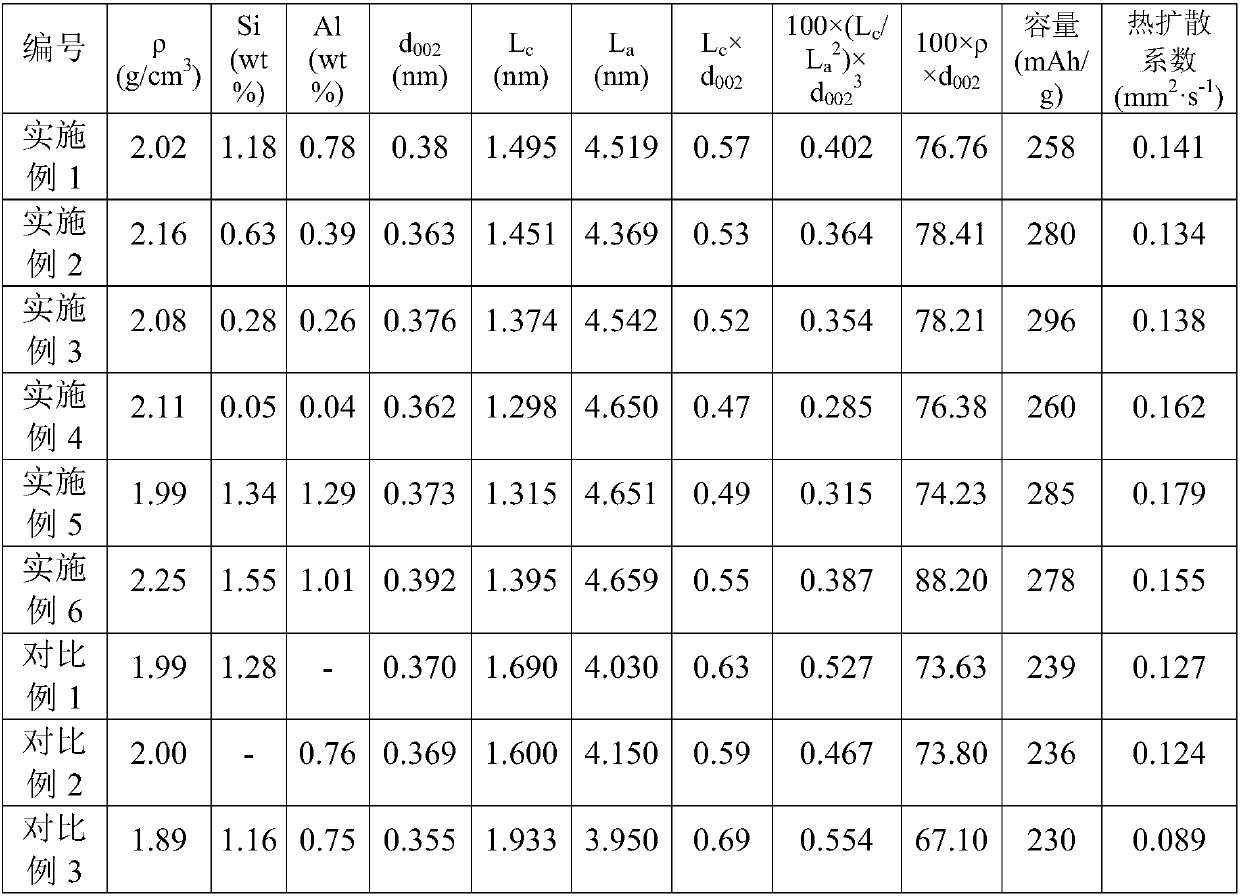

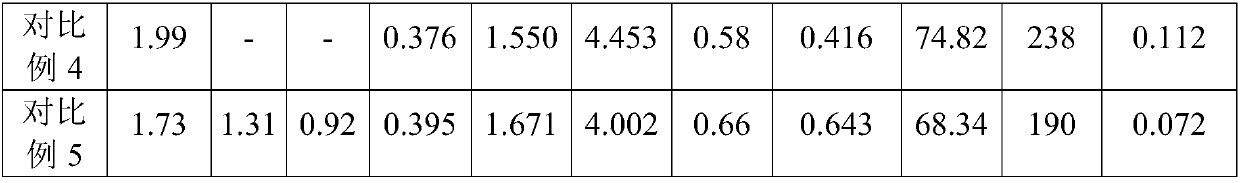

Examples

Embodiment 1

[0104] Mesophase pitch (98% by weight carbon content, 50% mesophase content) with a softening point of 260°C and aluminum silicate (Al 2 (SiO 3 ) 3 ) is mixed according to the mass ratio of 96:4, and the mixture is pulverized by a small ultrafine pulverizer to obtain D 50 =50μm powder, the powder is ball milled at 300rpm by an omnidirectional planetary ball mill to obtain D 50 = 10 μm powder.

[0105] Add gum arabic to water, and prepare a solution with a concentration of 2% by weight under the condition of a water bath at 80°C. Add the aforementioned ball-milled powder into the solution, the mass ratio of powder to solution is 20:100, stir at 80°C for 4 hours, then let it stand at room temperature, remove the upper liquid, and vacuum-dry the obtained solid at 120°C for 12 hours. Place the dried powder in the tube furnace part of the OTF-1200X-80-III-F3LV system, pre-fire at 600°C for 10 hours under nitrogen atmosphere, then raise the temperature to 1300°C, and fire at thi...

Embodiment 2

[0107] Mesophase pitch (99 wt% carbon content, 90% mesophase content) with a softening point of 320°C and aluminum silicate (Al 2 (SiO 3 ) 3 ) is mixed according to the mass ratio of 98:2, and the mixture is pulverized by a small ultrafine pulverizer to obtain D 50 =80μm powder, the powder is ball-milled at 300rpm by a full-range planetary ball mill to obtain D 50 = 25 μm powder.

[0108] Add gum arabic to water, and prepare a solution with a concentration of 0.01% by weight under the condition of a water bath at 80°C. Then add the ball-milled powder into the solution, the mass ratio of powder to solution is 20:100, stir at 80°C for 4 hours, then let it stand at room temperature, remove the upper liquid, and vacuum-dry the obtained solid at 120°C for 12 hours . The dried powder was placed in the tube furnace part of the OTF-1200X-80-III-F3LV system, and fired at 1600 ° C for 1 hour under a nitrogen atmosphere to obtain D 50 = 29 μm amorphous carbon material.

Embodiment 3

[0110] Petroleum pitch (carbon content 86% by weight) with a softening point of 45°C and kaolin (Al 2 o 3 2SiO2 2 2H 2 O) mix according to the mass ratio of 99:1, the mixture is pulverized by a small ultrafine pulverizer to obtain D 50 =30μm powder, the powder is ball-milled at 300rpm by a full-range planetary ball mill to obtain D 50 = 10 μm powder.

[0111] Add sodium carboxymethyl cellulose to water, and prepare a solution with a concentration of 0.1% by weight under the condition of a water bath at 80°C. Then add the aforementioned ball-milled powder into the solution, the mass ratio of the powder to the solution is 20:100, stir at room temperature for 4 hours, then stand at room temperature, remove the upper liquid, and vacuum-dry the obtained solid at 120°C for 12 hours . The dried powder was placed in the tube furnace part of the OTF-1200X-80-III-F3LV system, and fired at 900 ° C for 20 hours under a nitrogen atmosphere to obtain D 50 = 13 μm amorphous carbon mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal diffusivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com