Flexible temperature sensor and preparation method thereof

A temperature sensor, flexible technology, applied in thermometers, thermometer parts, thermometers with direct heat-sensitive electric/magnetic elements, etc., can solve temperature measurement point drift, low thermal diffusivity, temperature measurement point drift and Long thermal diffusion time and other issues, to achieve the effect of increased temperature response speed and high thermal diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the implementation methods and accompanying drawings.

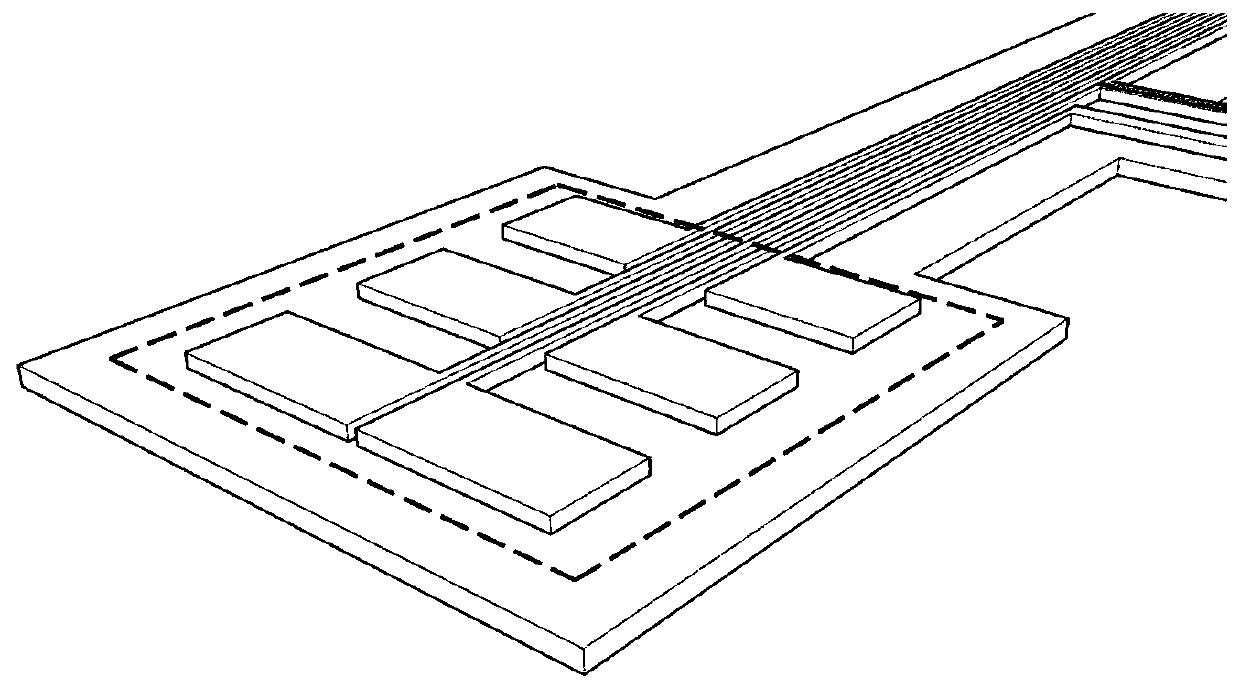

[0029] A flexible temperature sensor, comprising: a first flexible substrate, a first encapsulation layer, a second flexible substrate and a second encapsulation layer, the first flexible substrate is in a comb-like structure, on which external electrodes, wires and measurement The temperature electrode, the external electrode is set on the comb handle of the first flexible base, and is used to connect with the external device, the temperature measuring electrode is set at the end of the comb, and is connected with the external electrode through a wire, and the second n uniformly distributed cavities containing liquid metal are arranged on the flexible substrate, the temperature-measuring electrodes are suspended in the center of the cav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com