High-pressure source removing device

A source device and high-voltage technology, applied in the field of high-voltage source device, can solve the problems of occupying space and large amount of construction work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

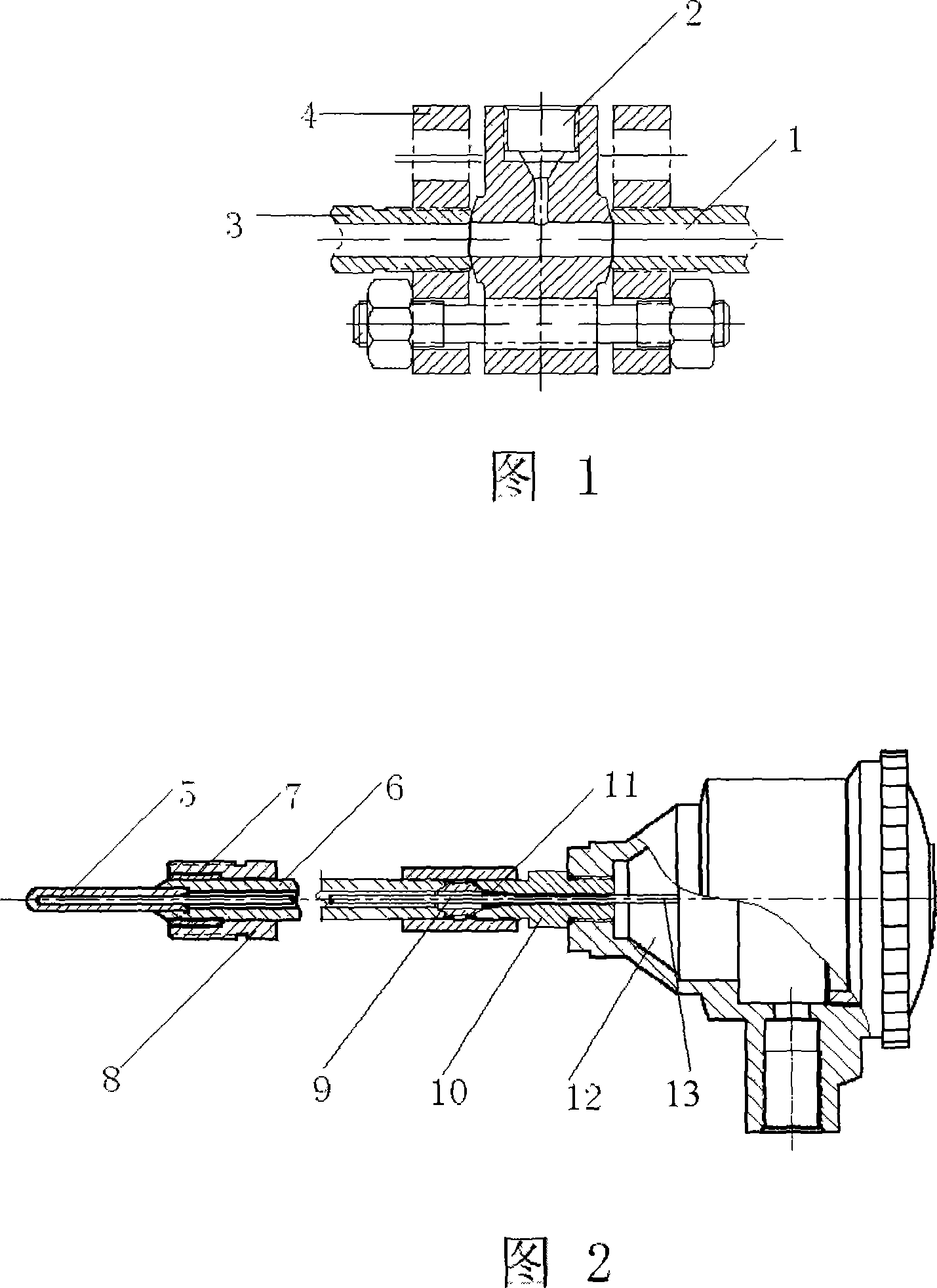

[0029] As shown in Figure 1, the main body of the lens-type high-voltage source component has a through hole 1 matching the pipeline to be detected, and a detection port 2 is opened on the main body, and the detection port communicates with the aforementioned through hole. The detection port can be a variable-diameter port with a large outer diameter and a smaller inner diameter. Multiple detection ports can be set, and can be used as temperature measurement detection ports or pressure measurement detection ports. During installation, the lens-type high-voltage source component is installed between two threaded flanges 4 of the detected high-pressure pipeline 3 .

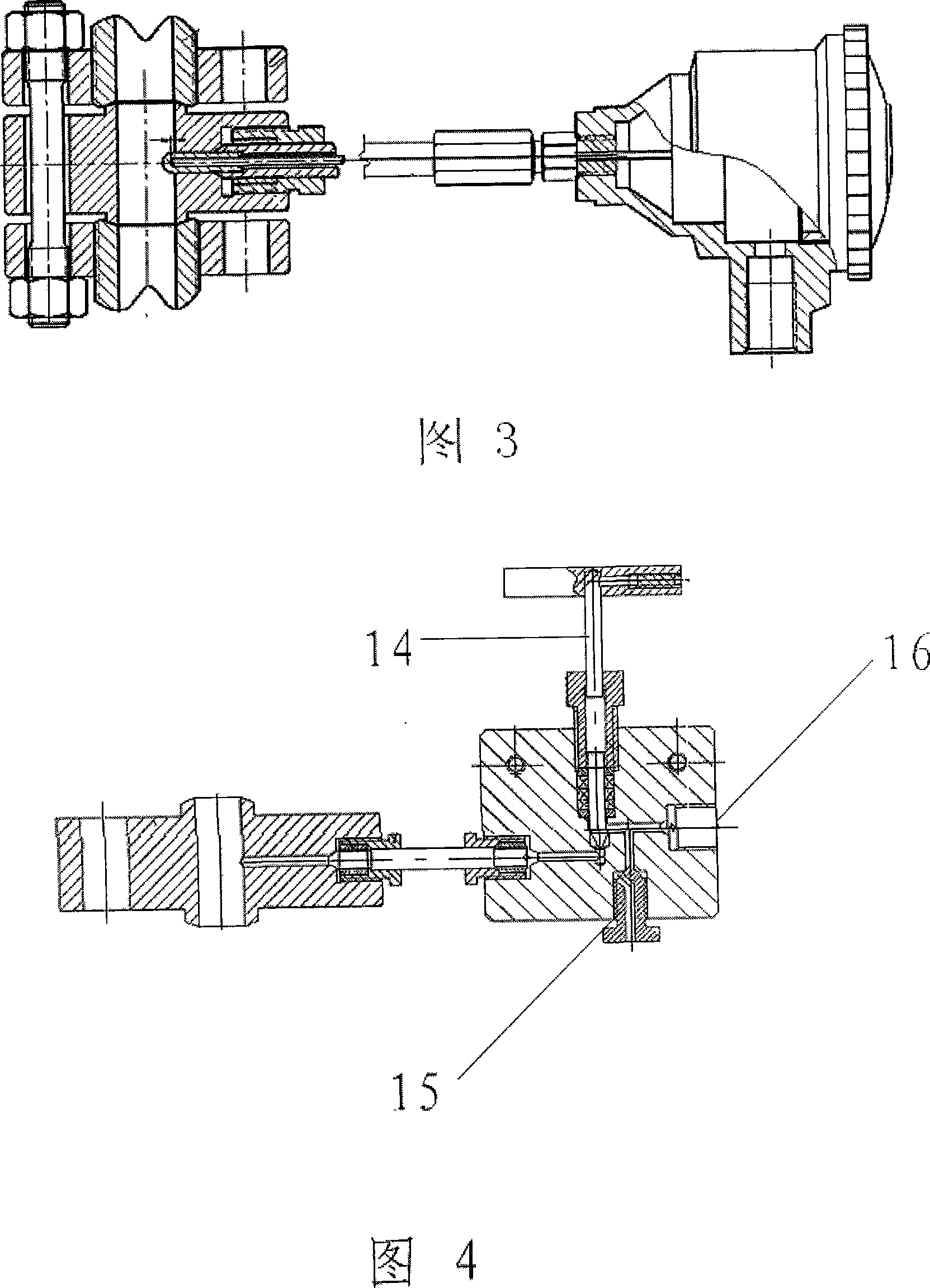

[0030] As shown in Figure 2 and Figure 3, when measuring temperature, a temperature measuring end sleeve 5 and a sleeve 6 are installed in the detection port, and one end of the sleeve is connected to the end sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com