Preparing method of pH control porous material for oil/water separation

A technology of porous material and water phase is applied in the field of preparation of porous materials to achieve the effects of low material density, mild reaction conditions and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

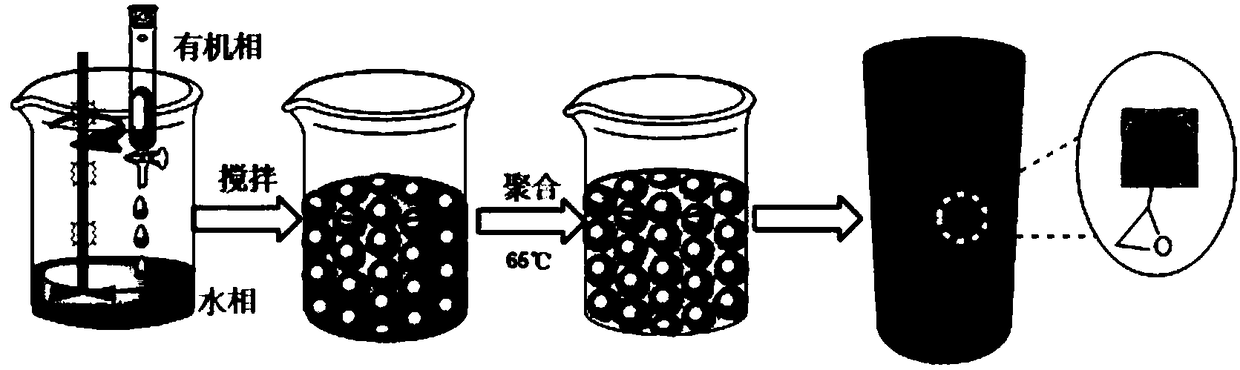

[0031] A preparation method of a porous material used for oil / water separation by pH regulation, the porous material in this embodiment is a porous structure with uniform distribution of pores; a preliminary porous material containing epoxy groups is obtained by high internal phase emulsion polymerization, and the porous material containing epoxy groups is obtained by containing The porous material is prepared by the ring-opening reaction of the tertiary amino compound and the epoxy group of the preliminary porous material.

[0032] The schematic diagram of the preliminary porous material synthesis in this example is as follows figure 1 shown.

[0033] The schematic diagram of porous material obtained by functionalization in this embodiment is as follows figure 2 shown.

[0034] The preparation method of the porous material and the functionalized porous material of the present embodiment is as follows:

[0035] In the reactor, the first monomer glycidyl methacrylate (cont...

Embodiment 1

[0038] In the reactor, the first monomer glycidyl methacrylate and the second monomer styrene (the molar ratio of glycidyl methacrylate to styrene is 50:50), a certain proportion of toluene (50% in The total mass of the first monomer and the second monomer), the crosslinking agent (5% in the total moles of the first monomer and the second monomer) and the emulsifier (20% in the total mass of the organic phase) are mixed uniformly at 350r Under the rotating speed of / min, initiator (2% is in the total mass of the first monomer and the second monomer) and CaCl 2 (1% in the mass of the aqueous phase) composed of an aqueous phase (the volume ratio of the aqueous phase to the organic phase is 90:10) was added dropwise to the reactor. After the dropwise addition, adjust the speed to 700r / min, stir for 30 minutes, transfer the emulsion system to a fixed container, seal it, and react at 60°C for 12h. The porous material is obtained by immersing and washing in deionized water, followe...

Embodiment 2

[0043] In the reactor, the first monomer glycidyl methacrylate and the second monomer styrene (the molar ratio of glycidyl methacrylate to styrene is 70:30), a certain proportion of toluene (50% in The total mass of the first monomer and the second monomer), the crosslinking agent (10% in the total moles of the first monomer and the second monomer) and the emulsifier (20% in the total mass of the organic phase) are mixed uniformly at 350r Under the rotating speed of / min, initiator (2% is in the total mass of the first monomer and the second monomer) and CaCl 2 (1% in the mass of the aqueous phase) composed of an aqueous phase (the volume ratio of the aqueous phase to the organic phase is 90:10) was added dropwise to the reactor. After the dropwise addition, adjust the speed to 700r / min, stir for 30 minutes, transfer the emulsion system to a fixed container, seal it, and react at 60°C for 12h. Deionized water immersion washing followed by ethanol immersion washing to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com