Nitrogen-doped self-shrinking 3D graphene for capacitive deionization electrode and preparation method thereof

A technology of capacitive deionization and graphene, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as poor anion and cation, large pore structure, and influence on the CDI ability of three-dimensional graphene, so as to avoid Effects of decreased specific surface area, increased specific surface area, and excellent CDI capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

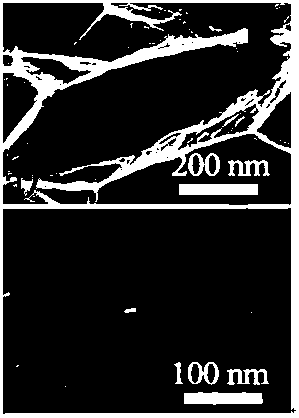

[0024] Add 2.5 mL of 98% pyrrole to 30 mL of homogeneous graphene oxide aqueous solution with a concentration of 2 mg / mL, and mix uniformly for 20 min. Get above-mentioned aqueous solution and add in the hydrothermal kettle, then hydrothermally 12 hours at 180 ℃. After the graphene oxide hydrogel obtained in the above steps was washed 3 times with deionized water, the graphene hydrogel was subjected to self-shrinkage treatment. The self-shrinking treatment is: place the washed graphene hydrogel at 25°C for 3h, add 0.08mol / L ethylenediamine to react for 6h, wash with deionized water, and place at 25°C for 2h. The shrunken graphene hydrogel was then freeze-dried to preserve its internal pore structure. Finally, the freeze-dried nitrogen-doped porous 3D graphene was placed in a tube furnace and annealed with Ar gas at 1000°C for 2 hours, and the product nitrogen-doped self-shrinking porous 3D graphene (N-S3DG) was finally obtained. .

Embodiment 2

[0026] Add 2.5 mL of 98% pyrrole to 30 mL of homogeneous graphene oxide aqueous solution with a concentration of 2 mg / mL, and mix uniformly for 20 min. Get above-mentioned aqueous solution and add in the hydrothermal kettle, then hydrothermally 12 hours at 180 ℃. After the graphene oxide hydrogel obtained in the above steps was washed 3 times with deionized water, the graphene hydrogel was subjected to self-shrinkage treatment. The self-shrinking treatment is: place the washed graphene hydrogel at 20°C for 3h, add 0.08mol / L ethylenediamine to react for 6h, wash with deionized water, and place at 20°C for 2h. The shrunken graphene hydrogel was then freeze-dried to preserve its internal pore structure. Finally, the freeze-dried nitrogen-doped porous 3D graphene was placed in a tube furnace and annealed with Ar gas at 1000°C for 2 hours, and the product nitrogen-doped self-shrinking porous 3D graphene (N-S3DG) was finally obtained. .

Embodiment 3

[0028] Add 2.5 mL of 98% pyrrole to 30 mL of homogeneous graphene oxide aqueous solution with a concentration of 2 mg / mL, and mix uniformly for 20 min. Get above-mentioned aqueous solution and add in the hydrothermal kettle, then hydrothermally 12 hours at 180 ℃. After the graphene oxide hydrogel obtained in the above steps was washed 3 times with deionized water, the graphene hydrogel was subjected to self-shrinkage treatment. The self-shrinking treatment is as follows: place the washed graphene hydrogel at 30°C for 3h, add 0.08mol / L ethylenediamine to react for 6h, wash with deionized water, and place at 30°C for 2h. The shrunken graphene hydrogel was then freeze-dried to preserve its internal pore structure. Finally, the freeze-dried nitrogen-doped porous 3D graphene was placed in a tube furnace and annealed with Ar gas at 1000°C for 2 hours, and the product nitrogen-doped self-shrinking porous 3D graphene (N-S3DG) was finally obtained. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com