A kind of polydimethylsiloxane/nanometer cellulose composite film and preparation method thereof

A technology of polydimethylsiloxane and dimethylsiloxane, which is applied in the field of polydimethylsiloxane/nanocellulose composite film and its preparation, and can solve problems such as poor mechanical strength and easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

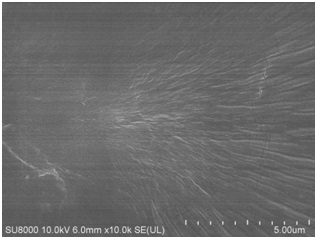

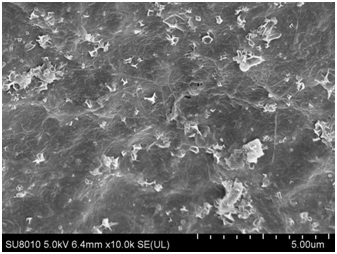

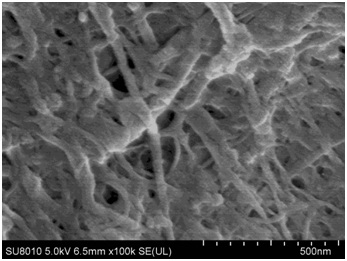

Image

Examples

preparation example Construction

[0034] A preparation method of polydimethylsiloxane / nanocellulose composite film, comprising the following process steps:

[0035] S01 Extraction of cellulose from bamboo powder

[0036] Preparation of Nanocellulose by S02 Mechanical Grinding-High Pressure Homogenization

[0037] Preparation of Nanocellulose Membrane by S03 Vacuum Filtration

[0038] Preparation of Polydimethylsiloxane / Nanocellulose Composite Membrane by S04 Solvent Displacement-Dipping Method

[0039] The step S01 extracts cellulose from bamboo powder, and has the following process steps:

[0040] (1) Add an appropriate amount of 80-100 mesh bamboo powder into deionized water, prepare 1700-2000ml of a suspension with a mass fraction of 1-1.5wt%, and stir magnetically for 0.5-1h to fully contact the bamboo powder with deionized water. Set 10h~12h.

[0041] (2) Weigh an appropriate amount of sodium chlorite to prepare a sodium chlorite solution with a concentration of 0.8-1 wt%; weigh the acetic acid soluti...

Embodiment 1

[0062] A kind of polydimethylsiloxane / nanometer cellulose composite membrane, is made up of following process steps:

[0063] (1) Add 10 g of 80-mesh bamboo powder into deionized water, prepare a suspension with a mass fraction of 1 wt%, stir it magnetically for 0.5 h, make the bamboo powder fully contact with deionized water, and let stand for 10 h.

[0064] (2) Weigh 10g of sodium chlorite and make it into a sodium chlorite solution with a concentration of 0.8wt%; weigh the acetic acid solution with a mass ratio of sodium chlorite and acetic acid solution of 4:1, first take the required solution Add 1 / 3 into the beaker of (1), heat and stir in a water bath at 80°C for 1 hour, then add the remaining solution in 2 times according to the above process, and vacuum filter the obtained sample with a Buchner funnel. Then rinse repeatedly with deionized water, and vacuum filter the sample with a Buchner funnel until the filtered solution is neutral.

[0065] (3) Weigh potassium hyd...

Embodiment 2

[0073] In Example 2, the impregnation concentration of polydimethylsiloxane is 1 wt%, that is, the nanocellulose membrane is dipped in a 1 wt% polydimethylsiloxane prepolymer solution, and then cured by heating. The polydimethylsiloxane content in the prepared polydimethylsiloxane / nanocellulose composite film was calculated to be 23.7%±4.1%. The polydimethylsiloxane / nanocellulose composite film was cut into a width of 5 mm and a length of 35 mm. Measure and record the thickness and width of the sample, clamp the sample between the fixtures, and ensure that the span is between 20-30mm. The universal mechanical testing machine (Model3365; Instron Corp., Canton, MA) was set with a load of 1 kN and a loading speed of 2 mm / min to test the tensile strength and Young's modulus of the samples. The test results of tensile properties show that the elongation at break of the composite film is 3.03%, the modulus of elasticity is 1617MPa, and the tensile strength is 32MPa; the elongation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com