Preparation method of phosphorus ammonium compound fertilizer

A compound fertilizer and ammonium phosphate technology, which is applied in ammonium orthophosphate fertilizer, phosphate fertilizer, alkaline orthophosphate fertilizer, etc., can solve the problems of increased cost and lack of fertilizer, and achieve the effects of preventing loss, improving soil, and improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

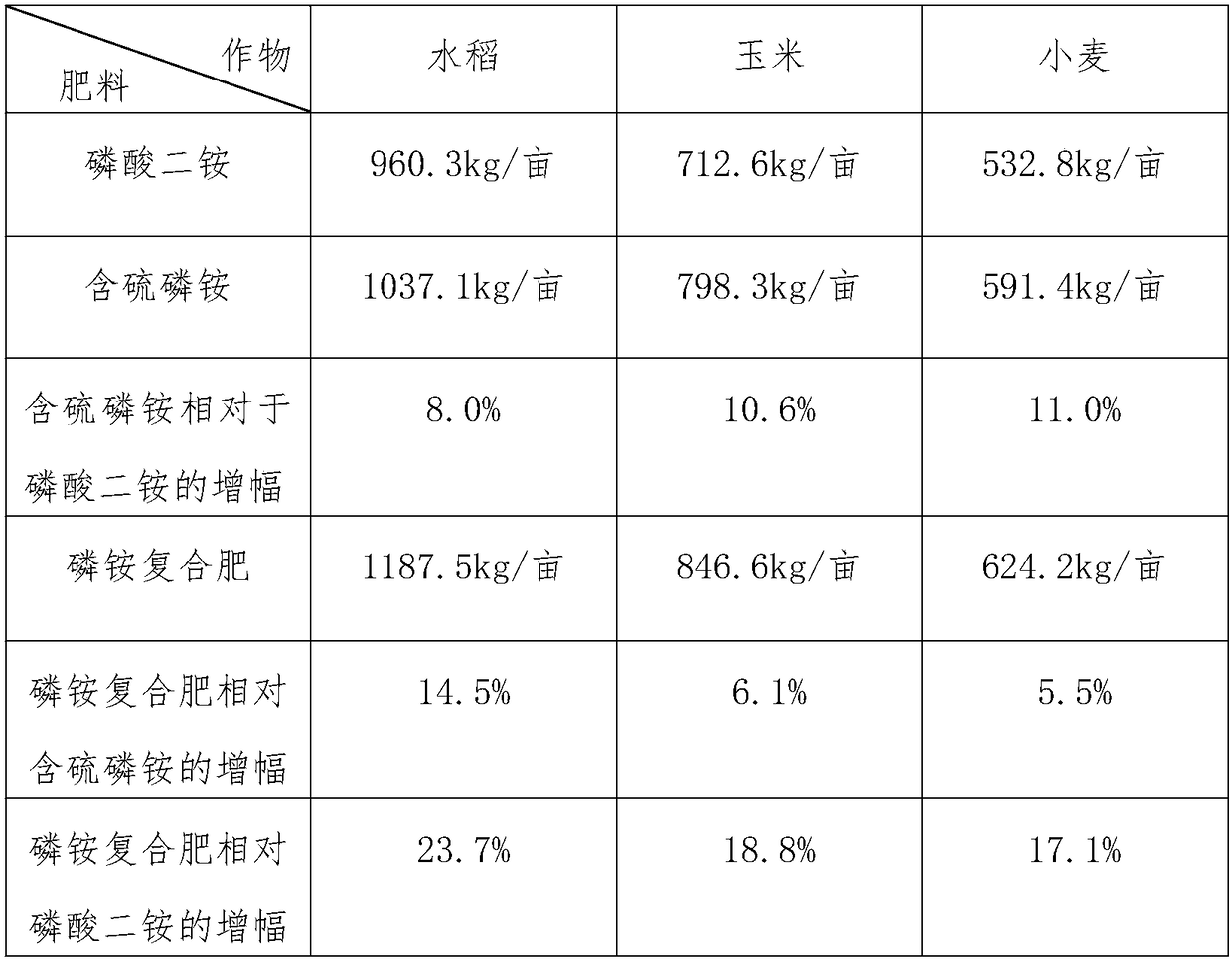

Examples

Embodiment 1

[0021] A preparation method for ammonium phosphate compound fertilizer, comprising the following steps:

[0022] (1) Sodium silicate, potassium fulvic acid, sodium lauryl sulfate are mixed with water, heated to make a very mixed solution, cooled, and set aside;

[0023] (2) adding the sulfur powder and the mixed solution into the wet milling system, and sieving after wet milling, the mixed material with a solid content of 40%;

[0024] (3) The mixed material is transported to the reactor of the diammonium phosphate plant to react with the ammonium phosphate slurry to make the mixed slurry;

[0025] (4) Part of the mixed slurry is sent to the reactor of the diammonium phosphate plant as a return material, and the remaining slurry is sent to the diammonium phosphate granulator for granulation to obtain pellets.

[0026] (5) The pellets are finally dried in a drier until the water content is lower than 3%, and then sieved and crushed to obtain ammonium phosphate compound fertili...

Embodiment 2

[0034] A preparation method for ammonium phosphate compound fertilizer, comprising the following steps:

[0035] (1) Sodium silicate, potassium fulvic acid, sodium lauryl sulfate are mixed with water, heated to make a very mixed solution, cooled, and set aside;

[0036] (2) adding the sulfur powder and the mixed solution into the wet milling system, and sieving after wet milling, the mixed material with a solid content of 46%;

[0037] (3) The mixed material is transported to the reactor of the diammonium phosphate plant to react with the ammonium phosphate slurry to make the mixed slurry;

[0038] (4) Part of the mixed slurry is sent to the reactor of the diammonium phosphate plant as a return material, and the remaining slurry is sent to the diammonium phosphate granulator for granulation to obtain pellets.

[0039] (5) The pellets are finally dried in a drier until the water content is lower than 3%, and then sieved and crushed to obtain ammonium phosphate compound fertili...

Embodiment 3

[0047] A preparation method for ammonium phosphate compound fertilizer, comprising the following steps:

[0048] (1) Sodium silicate, potassium fulvic acid, sodium lauryl sulfate are mixed with water, heated to make a very mixed solution, cooled, and set aside;

[0049] (2) adding the sulfur powder and the mixed solution into the wet milling system, and sieving after the wet milling, the mixed material with a solid content of 60%;

[0050] (3) The mixed material is transported to the reactor of the diammonium phosphate plant to react with the ammonium phosphate slurry to make the mixed slurry;

[0051] (4) Part of the mixed slurry is sent to the reactor of the diammonium phosphate plant as a return material, and the remaining slurry is sent to the diammonium phosphate granulator for granulation to obtain pellets.

[0052] (5) The pellets are finally dried in a drier until the water content is lower than 3%, and then sieved and crushed to obtain ammonium phosphate compound fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com