Rare-earth-based light absorption material and preparation method and application thereof

A light-absorbing material, rare-earth-based technology, applied in the direction of rare-earth metal compounds, chemical instruments and methods, rare-earth metal oxides/hydroxides, etc., to achieve low cost, simple operation, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

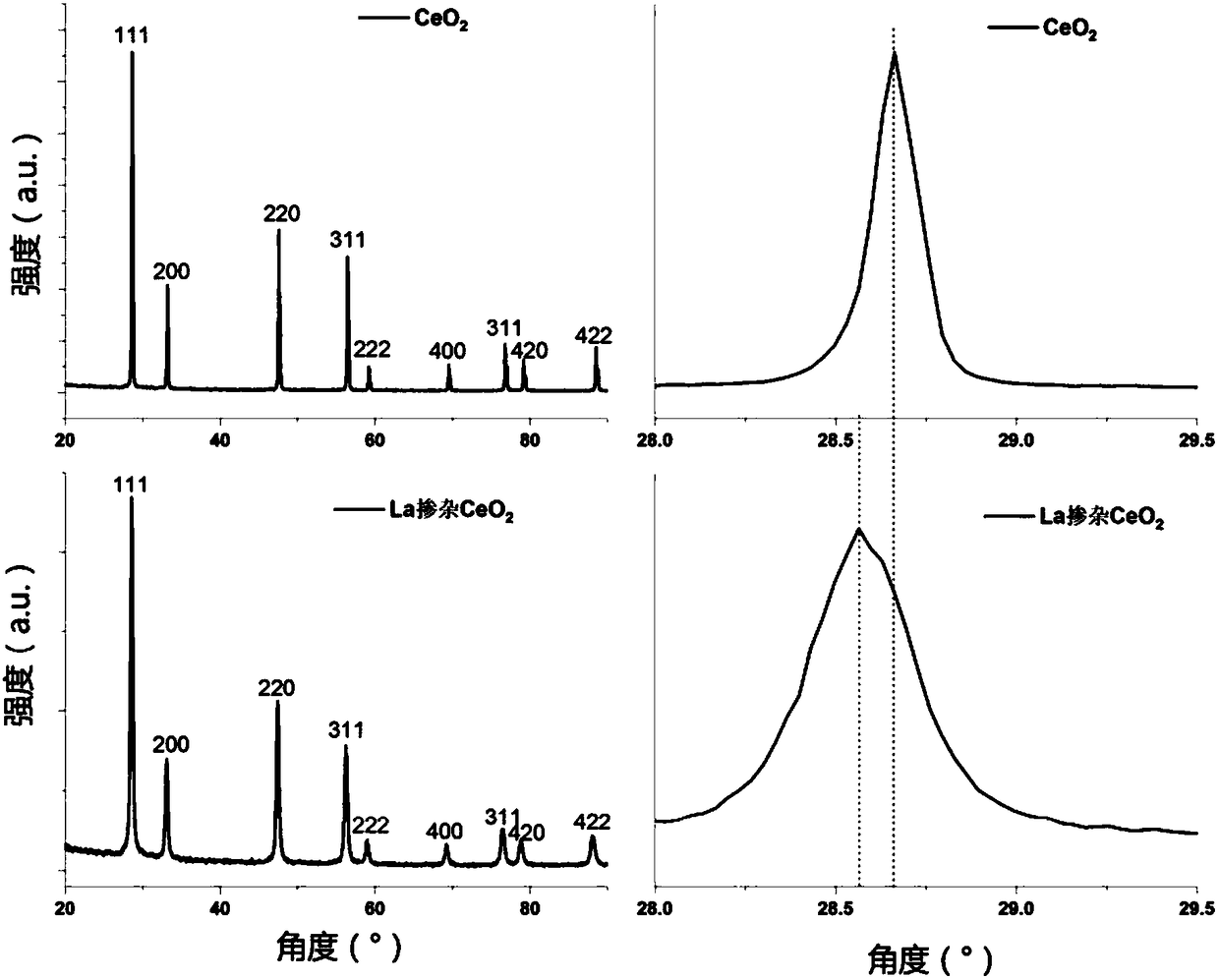

[0039] The steps of preparing the cerium oxide powder material doped with lanthanum are as follows:

[0040] 1. The rare earth chloride solution is prepared according to a certain mass ratio of the lanthanum and cerium elements, so that the lanthanum elements account for 5% to 15% of the mass of the lanthanum and cerium elements. The prepared rare earth chloride solution is composed of cerium chloride and lanthanum chloride.

[0041] 2. Preparation of rare earth oxalic acid precipitate: Add the prepared saturated oxalic acid solution to the rare earth chloride solution. During the precipitation process, the liquid phase temperature is kept between 20°C and 40°C. After all the rare earth elements in the solution are precipitated , for suction filtration.

[0042] 3. The rare earth oxalate precipitate obtained after suction filtration is sintered at high temperature, the sintering temperature is between 700°C and 950°C, and the sintering time is generally between 1h and 3h.

...

Embodiment 2

[0046] Specifically, lanthanum carbonate and cerium carbonate containing crystal water are used as raw materials to prepare a rare earth chloride solution. Firstly, lanthanum carbonate and cerium carbonate were dissolved in 10mol / L concentrated hydrochloric acid, and the concentration of lanthanum and cerium in the lanthanum chloride and cerium chloride solution was determined by EDTA titration.

[0047] Prepare a mixed solution of lanthanum and cerium elements according to the mass ratio of lanthanum and cerium elements of 1:10, add oxalic acid solution to the mixed rare earth chloride solution, and perform suction filtration after all the rare earth elements in the solution are precipitated.

[0048] The precipitate was sintered at 800°C for 2 hours. After sintering, the precipitate taken out is the target product.

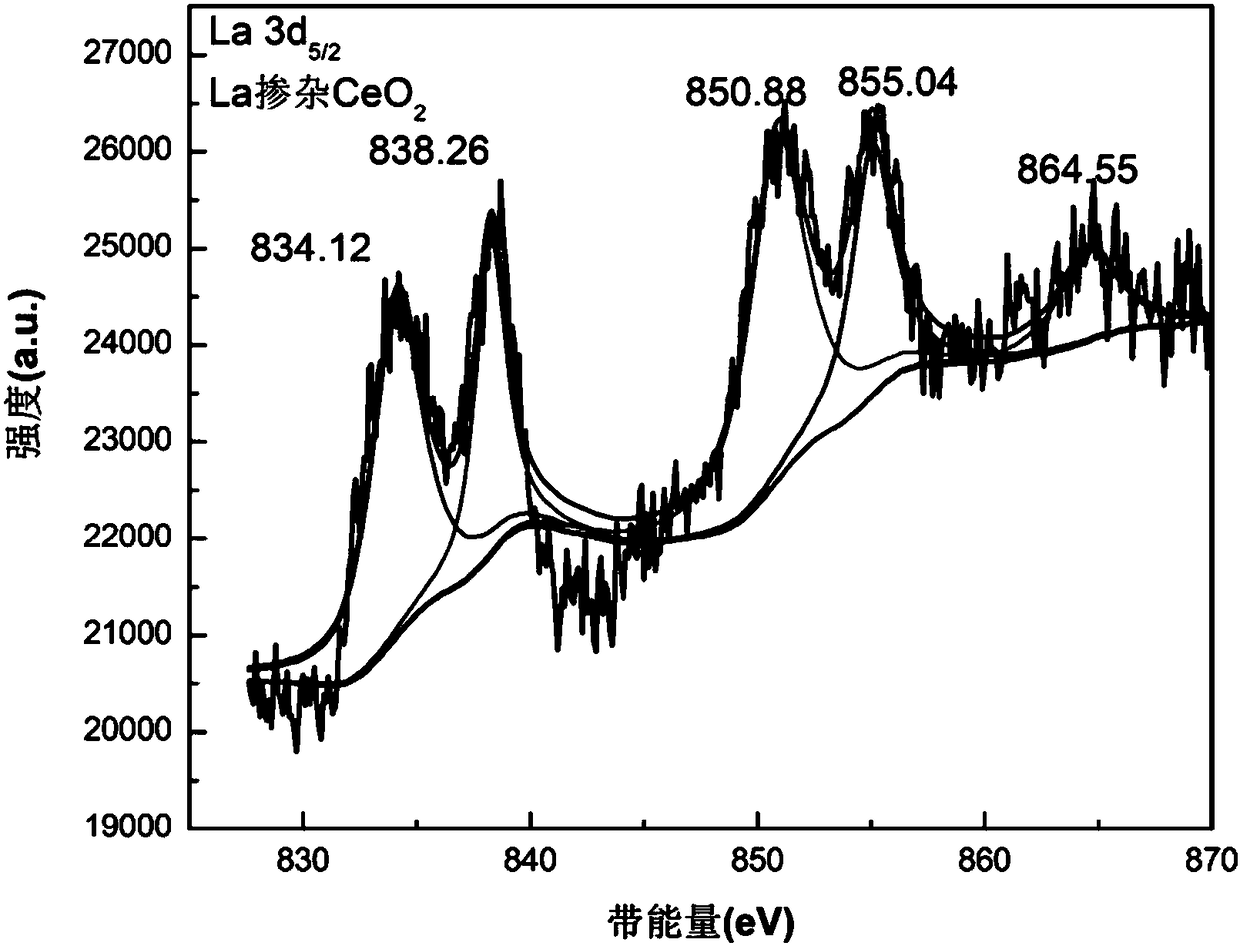

[0049] The ultraviolet-visible light absorption spectrum of the cerium oxide doped with lanthanum element prepared in this embodiment and pure cerium oxide is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com