One-step method for preparing wood-based activated carbon microspheres and its application

A technology based on activated carbon and wood, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as poisoning and increasing environmental pollution, and achieve the effects of reducing dependence, reducing poisoning and environmental pollution, and reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for preparing wood-based activated carbon microspheres in one step, and the specific steps are as follows:

[0038] 1) Mix 100g of 40-mesh wood powder obtained by crushing wood with 400g of phenol, add 50g of acidic catalyst phosphoric acid, and 25g of PEG600, keep warm at 130°C for 2h, and set aside;

[0039] 2) After fully mixing 25g of hexamethylenetetramine, 5g of polyethylene glycol and 100g of polyvinyl alcohol, add to the system obtained in step 1) and stir and keep warm at 130°C for 60min to form wood-based microspheres, which are pre-oxidized (heating Speed 1°C / min, heat up to 280°C, keep warm for 2h) and activation treatment (at a heating rate of 4°C / min, keep at a constant temperature of 800°C for 60min), to obtain wood-based activated carbon microspheres.

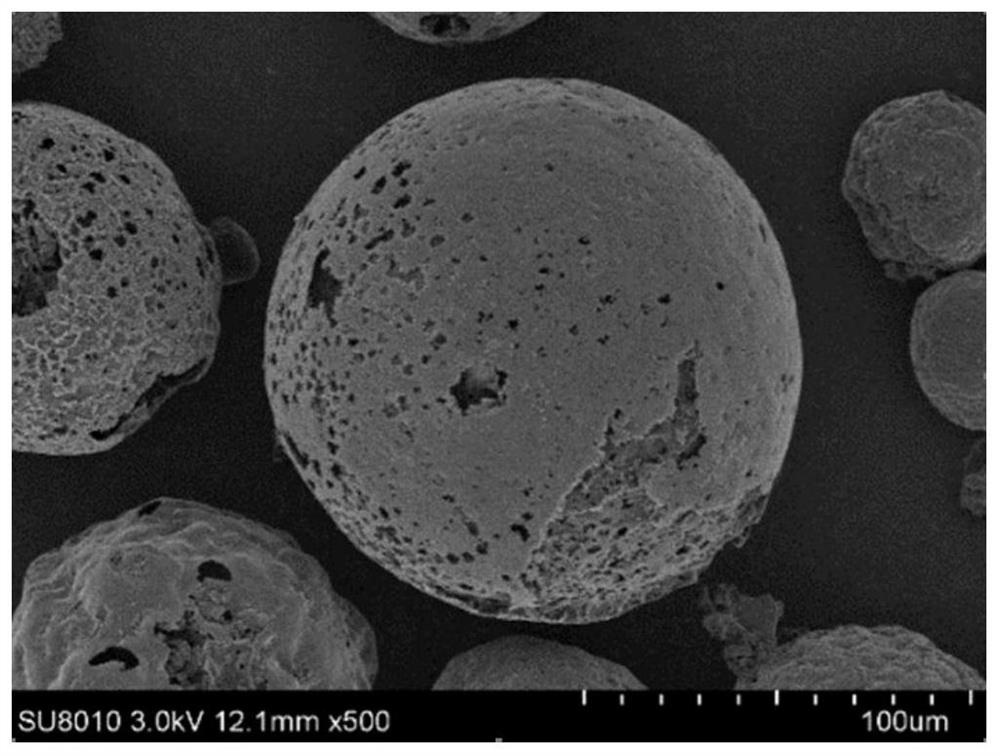

[0040] figure 1 It is the scanning electron microscope picture of the wood-based activated carbon microspheres prepared in Example 1.

Embodiment 2

[0042] This embodiment provides a method for preparing wood-based activated carbon microspheres in one step, and the specific steps are as follows:

[0043]1) Mix 100g of 40-mesh wood powder obtained by crushing wood with 300g of phenol, add 25g of acidic catalyst phosphoric acid, and 15g of PEG600, keep warm at 150°C for 3h, and set aside;

[0044] 2) After fully mixing 20g of hexamethylenetetramine, 20g of polyethylene glycol and 100g of polyvinyl alcohol, add to the system obtained in step 1) and stir and keep warm at 150°C for 120min to form wood-based microspheres, which are pre-oxidized (heating Speed 0.5°C / min, heating up to 250°C, holding for 1h) and activation treatment (at a heating rate of 4°C / min, 800°C constant temperature for 90min), to obtain wood-based activated carbon microspheres.

Embodiment 3

[0046] This embodiment provides a method for preparing wood-based activated carbon microspheres in one step, and the specific steps are as follows:

[0047] 1) Mix 100g of 60-mesh wood powder obtained by crushing wood with 500g of phenol, add 60g of acidic catalyst phosphoric acid, and 50g of PEG800, keep warm at 160°C for 2h, and set aside;

[0048] 2) After fully mixing 50g of hexamethylenetetramine, 5g of polyethylene glycol and 100g of polyvinyl alcohol, add it to the system obtained in step 1) and stir and keep warm at 160°C for 30min to form wood-based microspheres, which are pre-oxidized (heating Rate 2°C / min, heat up to 310°C, hold for 1h) and activation treatment (at a heating rate of 4°C / min, keep at a constant temperature of 900°C for 30min), to obtain wood-based activated carbon microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com