High-temperature-resistant in-adhesion PCV conveyer belt and preparing method thereof

A conveyor belt, high temperature resistant technology, applied in the field of high temperature resistant non-adhesive PVC conveyor belt and its preparation, can solve the problem of affecting the bonding strength of the covering rubber layer and the skeleton layer, prone to foaming, peeling or falling off, and unfavorable material transportation and other problems, to achieve the effect of increasing the Vicat softening point, not easy to peel or fall off, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

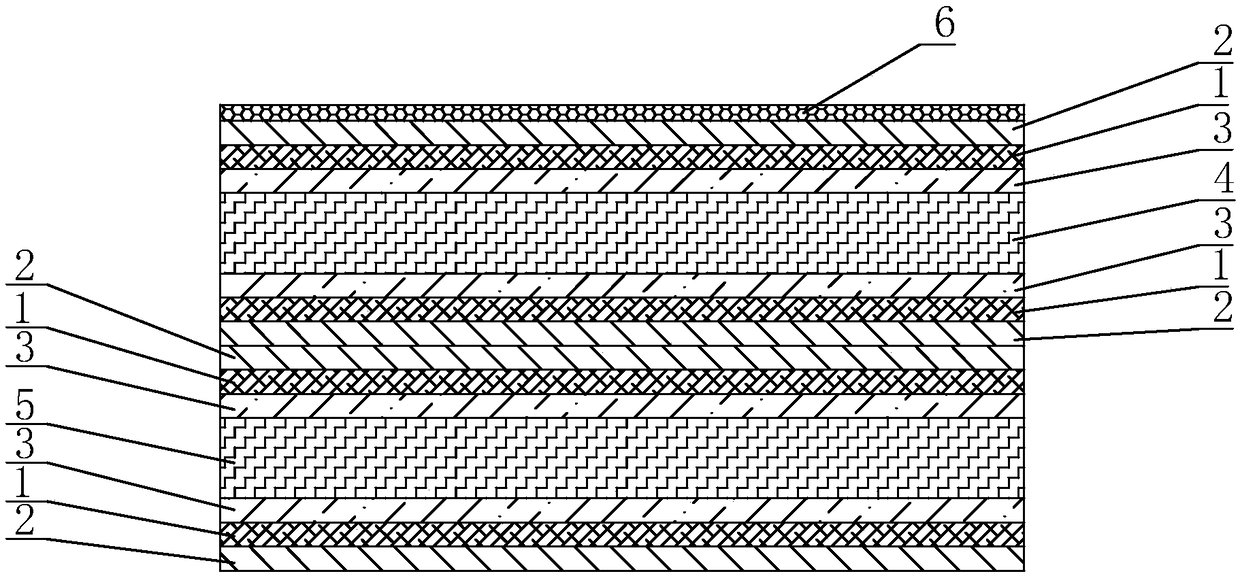

[0082] Embodiment 1: as figure 1 As shown, a high-temperature-resistant non-adhesive PVC conveyor belt includes a product skeleton and a surface glue. The product skeleton adopts a polyester fabric woven from polyester fibers. 1, and prepared by the following steps:

[0083] Step 1, polyvinyl chloride paste resin PB-128, 1 / 3 dioctyl terephthalate, 1 / 3 epoxy soybean oil, 1 / 3 N-cyclohexyl-2-benzothiazole The sulfenamide and 1 / 3 of the color paste were mixed and stirred, and vacuum defoamed to obtain the first slurry 1 with a viscosity of 4000Pa·s;

[0084] Step 2, polyvinyl chloride paste resin PB-108, PVC-KP-11 paste resin, 1 / 3 dioctyl terephthalate, 1 / 3 epoxy soybean oil, 1 / 3 N-ring Hexyl-2-benzothiazole sulfenamide, calcium carbonate, and 1 / 3 of the color paste were mixed and stirred, and vacuum defoamed to obtain a second slurry 2 with a viscosity of 4000 Pa·s;

[0085] Step 3, 1 / 3 of dioctyl terephthalate, 1 / 3 of epoxidized soybean oil, 1 / 3 of N-cyclohexyl-2-benzothiazol...

Embodiment 2-5

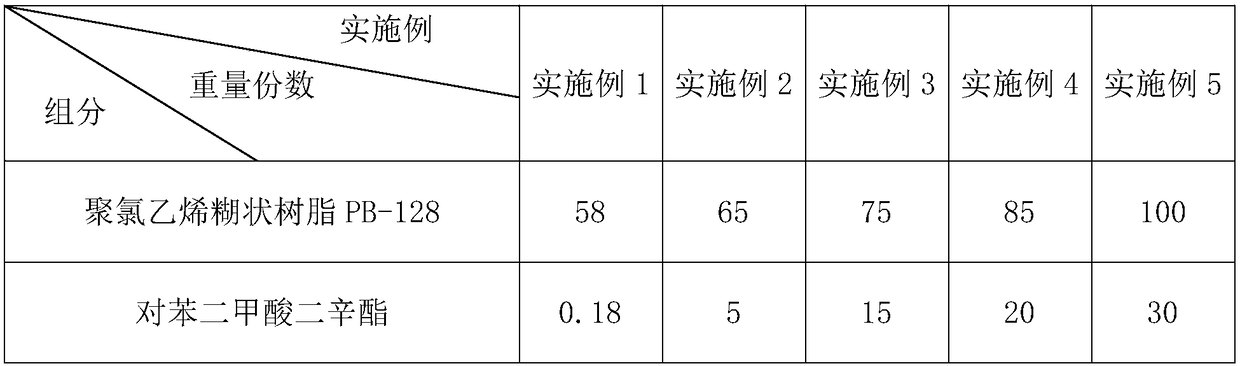

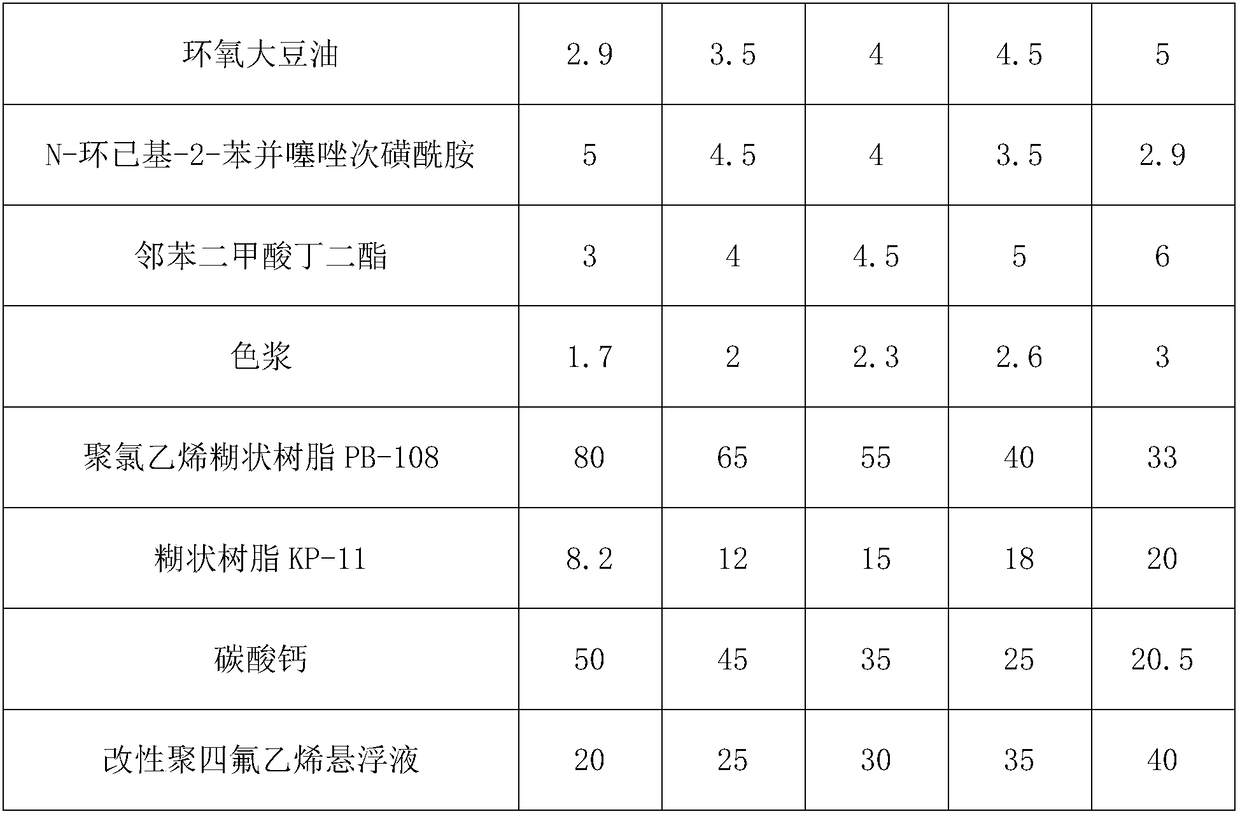

[0097] Example 2-5: A high temperature resistant non-adhesive PVC conveyor belt, the difference from Example 1 is that the components of the surface glue and their corresponding parts by weight are shown in Table 1.

[0098] Each component of face glue and parts by weight thereof in table 1 embodiment 1-5

[0099]

[0100]

Embodiment 6

[0101] Embodiment 6: A kind of high temperature resistant non-adhesive PVC conveyor belt, the difference with embodiment 1 is that the modified polytetrafluoroethylene suspension comprises the following components in parts by weight: 100 parts of polytetrafluoroethylene suspension , 4 parts of polyether ether ketone, 4 parts of molybdenum disulfide, 6 parts of titanium dioxide, 0.002 parts of titanate coupling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com