A regeneration method for dust removal and denitrification multifunctional filter material

A filter material regeneration, multi-functional technology, applied in filter regeneration, separation methods, chemical instruments and methods, etc., to achieve the effect of good impact resistance and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of cleaning solution

[0034] According to the mass ratio of 0.1:0.1:1, weigh the diffusing agent alkylphenol polyoxyethylene ether, ethanol and nitric acid with a molar concentration of 0.02mol / L, perform ultrasonic treatment for 30 minutes, mix them evenly, and prepare a cleaning solution.

[0035] 2. Preparation of regenerated catalytic membrane

[0036] ① Preparation of catalytic membrane blank

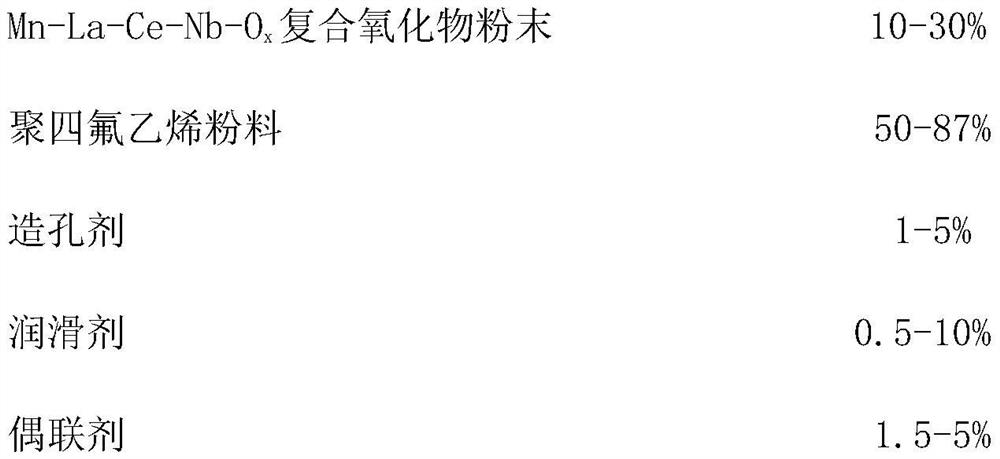

[0037] Step 1: Weigh 100g (10%) Mn-La-Ce-Nb-O x Composite oxide powder (Mn / La / Ce / Nb=1:0.1:0.1:0.1, the average particle size of catalyst powder is 0.1um), 870g (87%) tetrafluoroethylene powder, 10g (1%) polyethylene glycol Alcohol 400, 15g (1.5%) N-(β-aminoethyl)-γ-aminopropyltriethoxysilane, 5g (0.5%) oxidized polyethylene wax;

[0038] Step 2: Put the weighed powder into a stirrer for mixing and stirring, the stirring speed is 120 rpm, and the stirring time is 360 minutes. After taking it out, let it stand at 20°C for 48 hours to obtain the catalytic mem...

Embodiment 2

[0053] 1. Preparation of cleaning solution

[0054] According to the mass ratio of 0.5:0.3:1, weigh the diffusing agent alkylphenol polyoxyethylene ether, ethanol and nitric acid with a molar concentration of 0.15mol / L, perform ultrasonic treatment for 240min, mix them evenly, and prepare a cleaning solution.

[0055] 2. Preparation of regenerated catalytic membrane

[0056] ① Preparation of catalytic membrane blank

[0057] The first step: weigh 220g (22%) Mn-La-Ce-Nb-O x Composite oxide powder (Mn / La / Ce / Nb=1:0.2:0.25:0.25, the average particle size of catalyst powder is 0.2um), 655g (65.5%) tetrafluoroethylene powder, 30g (3%) polyethylene glycol Alcohol 600, 35g (3.5%) N-(β-aminoethyl)-γ-aminopropyltriethoxysilane, 60g (6%) isoparaffin solvent;

[0058] Step 2: Put the weighed powder into the mixer for mixing and stirring, the stirring speed is 500 rpm, and the stirring time is 180 minutes. After taking it out, let it stand at 35°C for 30 hours to obtain the catalytic me...

Embodiment 3

[0070] 1. Preparation of cleaning solution

[0071] Weigh the diffusing agent alkylphenol polyoxyethylene ether, ethanol and sulfuric acid with a molar concentration of 3mol / L according to the mass ratio of 1:1:1, and perform ultrasonic treatment for 360min to mix them evenly and prepare a cleaning solution.

[0072] 2. Preparation of regenerated catalytic membrane

[0073] ① Preparation of catalytic membrane blank

[0074] Step 1: Weigh 300g (30%) Mn-La-Ce-Nb-O x Composite oxide powder (Mn / La / Ce / Nb=1:0.3:1:0.5, the average particle size of catalyst powder is 0.5um), 500g (50%) tetrafluoroethylene powder, 50g (5%) polyethylene glycol Alcohol 800, 50g (5%) N-(β-aminoethyl)-γ-aminopropyl triethoxysilane, 100g (10%) isoparaffin solvent;

[0075] Step 2: Put the weighed powder into the mixer for mixing and stirring, the stirring speed is 800 rpm, and the stirring time is 120 minutes. After taking it out, let it stand at 60°C for 24 hours to obtain the catalytic membrane blank; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com