Antibacterial liquid toothpaste

A liquid toothpaste and mixed liquid technology, applied in the field of oral care, can solve the problems of low liquid viscosity, easy loss of active ingredients, poor bacteriostatic effect, etc., and achieve good compatibility, protection from damage, and mild tooth cleaning performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

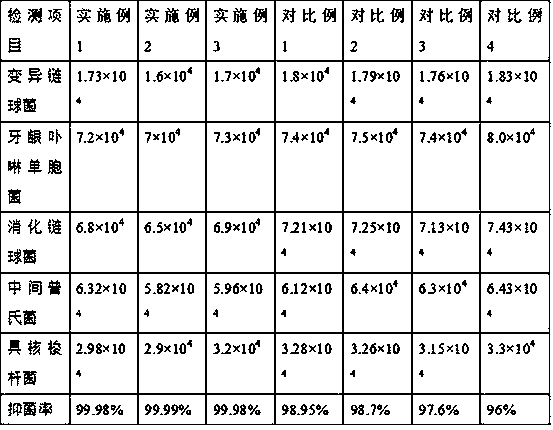

Examples

Embodiment 1

[0029] Friction agent: Take sodium silicate and add deionized water at a mass ratio of 1:8, stir and mix for 20 minutes, add sodium chloride with 2% of the mass of sodium silicate, heat up to 65°C, and then add 20% of the mass of sodium silicate 80% sulfuric acid, stirred and mixed for 30 minutes, then added 80% sulfuric acid with a mass fraction of 40% sodium bicarbonate and mixed to obtain a mixture. Take the mixture and mix it with hydroxyapatite at a mass ratio of 2:1 to obtain a friction agent .

[0030] Foaming agent: Take sodium lauroyl sarcosinate and mix it with propyl betaine cocoate at a mass ratio of 3:1 to obtain the product.

[0031] Moisturizing agent: take sorbitol and add xylitol and carboxymethyl cellulose in a mass ratio of 2:1:2 to mix.

[0032] Bactericidal active agent: take ethyl orthosilicate and mix it with calcium nitrate tetrahydrate at a mass ratio of 4:2 to obtain mixture a, take mixture a and add 80% ethanol at a mass ratio of 1:8, adjust the pH ...

Embodiment 2

[0037] Friction agent: Take sodium silicate and add deionized water at a mass ratio of 2:11, stir and mix for 25 minutes, add sodium chloride with 3% of the mass of sodium silicate, heat up to 67°C, and then add 25% of the mass of sodium silicate 80% sulfuric acid, stirred and mixed for 35 minutes, and then added 80% sulfuric acid with a mass fraction of 50% sodium bicarbonate and mixed to obtain a mixture. Take the mixture and mix it with hydroxyapatite at a mass ratio of 3:2 to obtain a friction agent .

[0038] Foaming agent: Take sodium lauroyl sarcosinate and mix it with propyl betaine cocoate in a mass ratio of 4:2.

[0039] Moisturizing agent: Take sorbitol and add xylitol and carboxymethyl cellulose in a mass ratio of 3:2:3 to mix.

[0040] Bactericidal active agent: take ethyl orthosilicate and mix it with calcium nitrate tetrahydrate at a mass ratio of 5:3 to obtain mixture a, take mixture a and add 80% ethanol at a mass ratio of 2:9, adjust the pH to 1.5, and stir ...

Embodiment 3

[0045] Friction agent: Take sodium silicate and add deionized water at a mass ratio of 3:12, stir and mix for 30 minutes, add sodium chloride with 5% of the mass of sodium silicate, heat up to 70°C, and then add 30% of the mass of sodium silicate 80% sulfuric acid, stirred and mixed for 40 minutes, then added 80% sulfuric acid with a mass fraction of 60% sodium bicarbonate and mixed to obtain a mixture. Take the mixture and mix it with hydroxyapatite at a mass ratio of 5:3 to obtain a friction agent .

[0046] Foaming agent: Take sodium lauroyl sarcosinate and mix it with propyl betaine cocoate at a mass ratio of 5:3.

[0047] Moisturizing agent: Take sorbitol and add xylitol and carboxymethyl cellulose in a mass ratio of 5:3:5 to mix.

[0048] Bactericidal active agent: take ethyl orthosilicate and mix it with calcium nitrate tetrahydrate at a mass ratio of 7:4 to obtain mixture a, take mixture a and add 80% ethanol at a mass ratio of 3:10, adjust the pH to 2, and stir Mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com